Search the Community

Showing results for tags 'Charcuterie'.

-

One taste which does vary hugely between cultures is what kind of bacon to eat, how to cook it and how to eat it. I was raised in England on medium thick rashers of bacon, fried only until just cooked through and still tender, with just a slight crunch to the outer strip of fat, or rind. I am vague on the correct terminology (and I am sure others here can fill me in), but we rarely ate what we called "streaky bacon" - the thin rashers with several strips of fat. In the States, of course, this is the most popular kind - as far as I can see - cooked absolutely crisp. I have been instructed that the correct way to eat this is to drop your utensils and use your fingers. Thick cut, meaty bacon can be found in New York. The excellent butchers on the Ninth Avenue food strip always have it, as does the considerably pricier French Butcher on Third. In a desperate pinch, I have sometimes bought a chunk of pancetta and cut makeshift rashers myself. So, lots of options: meaty, fatty, soft or crisp, smoked or unsmoked. I am scratching the surface here. Do people have strong views - I am particularly interested to know if crisp-bacon-eaters find the tender stuff aversive? I prefer tender, but will eat both.

-

I was going to put this in the Australia and New Zealand forum but I wonder if it is unique to us or cross-cultural. New to me Australian subculture - snapping the kabana. Apparently kabana originated in Poland but somehow became common here. I now know a kabana is a long skinny Polish sausage, kind of like a non-spicy pepperoni. Somehow I had missed that and that Australians have embraced kabana. When you buy one at the deli counter, they typically snap it in half to wrap it. According to the internet, only a mad person would want their kabana whole, but supposedly deli workers are trained to ask before snapping in case they encounter such a person. I, of course, had to buy one. The clerk snapped it in half without asking. I was very disappointed. Tastes good, though How do you eat kabana? Do you get it snapped in half when buying? Do they ask first?

-

The middle child has been yammering all summer for "brisket like we used to get in Texas." I don't have a smoker, but I've got a reasonably-sized (~ 22" x 36") grill. I'm pretty accomplished at ribs and chicken and the usual stuff, but I've never done a big hunk of meat on the grill, and I've never cooked fresh brisket in any form. Make my little girl happy and pass along some tips--I know there's some heavy smokers out there.

-

I LOVE BACON Im cooking bacon right now actually...how do you all cook it - do you flip it, cook until crispy or not...etc... I cook my bacon in a non stick fry pan ( all-clad) and flip often on medium heat until almost crispy - I make sure that the fat, however, has gotten brown...

-

I am looking for good sources on the process of making dried and/or cured sausages. I am fairly comfortable making fresh, but really need some direction when it comes to safely drying and curing them. Thanks and happy eating.

-

Pâtés & Terrines What can be more inviting than a slice of a carefully balanced, well spiced and rich pâté, perhaps with a fresh tart side salad and a warm crusty bread? Well, you’ll soon be in for exactly that treat: welcome to eGullet Cook-Off #89 - Pâtés & Terrines! Although at first glance* a bit more technical & complex than our previous wings topic, it offers plenty of space to explore and experiment: from a simple pâté de campagne to a foie gras-centered pâté en croute with a delectable pasty shell and a jellied Sauterne cover. There has been a longstanding topic on terrines with spectacular entries in the past, so we felt it would be more than justified to open the topic up for a spirited exchange in the course of our popular Cook-Offs. Typically something rather enjoyed in a restaurant setting (where these time-consuming, yet economical preparations have undergone a renaissance due to the nose-to-tail movement) or as a treat from your deli or traditional butcher, pâtés and terrines are surprisingly not difficult to prepare. They make – however – usually more than two servings, so maybe the upcoming Easter holidays could help to encourage you to give it a try and surprise your family and friends** … There are many definitions of what makes a pâté a pâté, and how and why terrines are different. I am happy to discuss with you the intricacies of these, but for setting a non-threatening starting point I’d like to think of both as a fancy meatloaf or maybe an oversized sausage (in a funky rectangular shape perhaps) with interesting, maybe surprising additions (such as liver, offal, nuts, dried and alcohol-soaked fruits), herbs, liquors and spices (quatre épice anyone?). What kind of meat do you prefer? The world is your oyster, and beside all types of game, domestic animals, poultry and fowl, fish & seafood (including said oyster) can be used as well. Do you like a smooth texture or a coarser product, maybe with inlays ? You can shape your loaf into animal shapes, wrap it in bacon, fatback or puff pastry perhaps and glaze it with any gelled liquid you fancy. I can already see your minds starting to get creative … Rabbit terrine from the Rabbit Cook-Off. So break out your books and magazines, peruse your favourite websites and maybe even show off tried & trusted family recipes and show us what you are capable of – if you can get ground meat and have an oven*** I’ll repeat my mantra: there is really no excuse this time 😊 See the complete eG Cook-Off Index here: https://forums.egullet.org/topic/143994-egullet-recipe-cook-off-index/ —- * well – having seen how much work can be put into a humble chicken wing, only at first glance. ** they make a terrific presents as well. *** or sous-vide setup, or …

-

It is possibly not well-known that China has some wonderful hams, up there with the best that Spain can offer. This lack of wide knowledge, at least in the USA, is mainly down to regulations forbidding their importation. However, for travellers to China and those in places with less restrictive policies, here are some of the best. This article from the WSJ is a good introduction to one of the best - Xuanwei Ham 宣威火腿 (xuān wēi huǒ tuǐ) from Yunnan province. This Ingredient Makes Everything Better I can usually obtain Xuanwei ham here around the Chinese New Year/Spring Festival, but I also have a good friend who lives in Yunnan who sends me regular supplies. The article compares it very favourably with jamon iberico, a sentiment with which I heartily agree. Xuanwei Ham Xuanwei Ham more coming soon.

-

Can anyone recommend a butcher who can handle an order for a pork belly? I want to try making my own bacon.

-

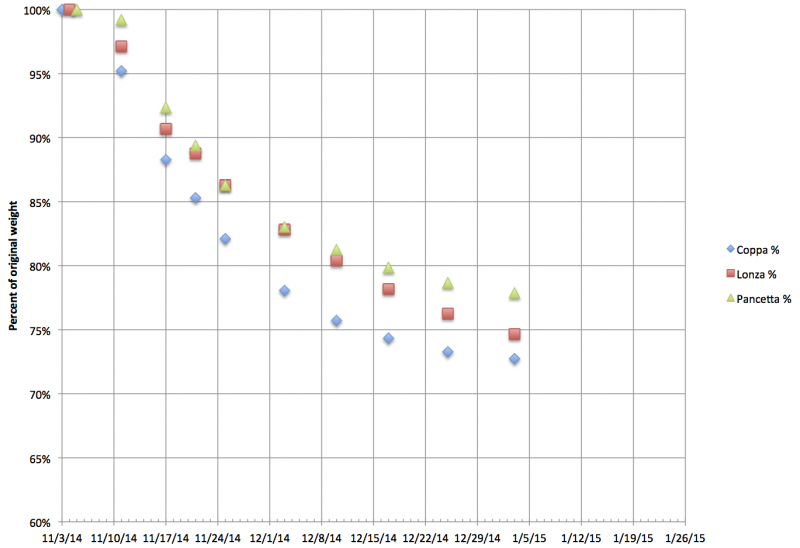

As I mentioned in the Half a Hog Fall 2014 topic, I'm doing a bunch of dry curing right now (in my new curing chamber!). Here's a plot of percent weight versus time as of today: I'm doing the cures according to Ruhlman and Polcyn's Salumi, so am targeting a 30% weight reduction. As you can see, however, while the Lonza is on track to achieve that level of reduction, both the coppa and the pancetta seem to be asymptotically approaching a final dried state that does not achieve the desired 30% reduction. Is this a problem, do you think? Should I keep them curing, or call them done?

-

Hi! i am working at a restaurant in south africa where we are curing our own meet. We are having a problem with tiny little white bugs (they look almost like lice) that are inside our leg hams. Does anyone know what they are and how we should get rid of them. the picture attached is the damage they have done on one of our legs.

-

This is elk bresaola 3 weeks after hanging in the drying chamber, and losing weight as expected. The growth on the outside seems mainly green on the outside of the netting. Probably safe... or pitch it? And if safe, wash or spray with anything? Strip the netting off, or...? Thank you

-

This is a product that has been mentioned in various threads here, but I don't think it's ever had one of it's own. This is a shame, because it seems intriguing. It promises the ability to do charcuterie and/or dry aging of steaks without a specialized room or curing chamber - just bags - all in your refrigerator. However like many products, their marketing lacks detail and it's difficult to discern exactly what is being claimed. But basically, the main product consists of specialized bags that will allow moisture out, but nothing else in (like oxygen). And another thing called a VacMouse - which is important in some way that is never totally explained. But the basic idea is that you're going to cure your meat in a standard way for 1-2 weeks and then vacuum pack it in the Dry Bag with the help of the VacMouse using a typical FoodSaver device. Then you just put it in the refrigerator on a rack and wait for weeks or months. Then you have bresaola, capicola, prosciutinni, lonzino, etc. After watching some online videos and doing some web searches, it appears that this may be a very useful thing - with some caveats.... First, dry aging of steaks seems to be a major marketing focus. But it looks like they're taking some criticism from dry aging enthusiasts who point out that without the exposure to oxygen, dry aging isn't really taking place. They are aging, and they're drying, but not with all the benefits of the traditional process. Yet, they do have some support in the form of positive reviews on various sites. For the same reasons, no one is going to challenge Parma for the best cured ham bites using this product. That's just a given. But it could offer something in between. And I'm not ready to build my curing chamber just yet. So I ordered a kit and it arrived today. It will probably be months before I know anything further, but I thought I'd relate what I've found so far. And I hope people who have used it will chime in. I'll have some waiting to do. The particular charcuterie kit I ordered from Amazon (I was using Amazon bucks) was 24.99 plus $8.99(!) shipping. For this I received 5 dry bags, 6 VacMouses, a packet of Instacure #2, and a packet of juniper berries - all packaged frugally, but practically, stored in an elongated ziplock bag between a cardboard brochure. It hardly seemed to justify an $8.99 shipping charge (although perhaps that was Amazon). Anyway, the good news is that after I examined everything, it all went back into it's original packaging without any fuss and awaits its call to duty. So, besides the cure and the spice, we have plastic bags and VacMouses. The plastic bags are apparently special because they will let the moisture out with out letting any of bad stuff from your refrigerator in. The VacMouses appear to be some sort of plastic fabric that make up for the fact that the bags do not have the channeling that FoodSaver bags do. Apparently, they will (along with the recommended crinkling of the neck of the bag) will take the place of those channels until they are sealed shut by the heat of the element. (and again by the recommended second sealing). It all seems plausible, and I feel supported by many wonderful pics on unaffiliated forums of beautifully sliced meats. But then again, I paid nearly $7.00/bag (including spice, and cure, and shipping). If you buy meat at $2/lb and put in a $5 bag, some calculations have to occur. But, of course, we're competing with the cost of high price specialty items or investments in curing chambers. Well, I guess we'll see.... (sorry for the long post, but I wanted to include all the information I wish I'd found upon learning of this product - as opposed to having to all the searching myself. And, also, I could be wrong in anything I have said. I haven't actually used the product.)

-

Hello! I'm not sure if the "cookbook" section of the forum is the best choice for this post, but... I recent was gifted "Dry-Curing Pork" by Hector Kent - a purely self serving gift from my boyfriend, I might add! I'm going to make the coppiette this weekend, and his instructions for slicing the loin are a bit vague to me. He directs to slice it in "... 3/4 inch strips at least 8 inches long." Do you suppose the 3/4" dimension refer to thickness of the slice (ie the smallest of 3 dimensions), or might he mean thinner slices that are 3/4" wide? Misinterpreting this would really change the cure/dry time... Am I making sense? Thoughts? And for fun, here's my report on my first attempt at his bacon recipe (among other things). Um... wow! http://operaflute.blogspot.com/2015/06/when-time-is-on-your-side-bacon-and.html Thanks!

-

I made some Lonza and cured it for 2 weeks. In the drying chamber (70% humidity and 55F with gentle air flow) it's only been 4 days but it's already lost 30% of its pre-drying chamber weight. Normally that can take weeks. Is that normal, and is the meat ready? Thank you

-

Novice at meat-curer looking for advice. I'm making 2 pancettas this season. The first one I used the over-salting technique. What I didn't expect was that the salt would all turn into brine in a day, and I expected that I could scrape away the excess salt at the end. Instead, I left it on the brine for too long, and the result was too salty. The meat firmed up in 2 days so I should've taken it out then. For my second one, which is currently in the fridge, I used the equilibrium salting technique. I added about 100g salt for 3.5kg meat. The problem now is that it's not firming up seemingly at all! It has been 9 days in the fridge, and flipping it every day or 2. After 6 days, however, there was no pool of brine left. I put the meat in a folded over but unsealed bag. Did the brine evaporate or resoak into the meat? Any advice on how to continue would be appreciated.

-

My first Guanciale is looking good. It smells clean, fresh, and is firming up nicely after about 3 weeks in the curing chamber at 65% humidity and 55F. First piece slices nicely and it seems great. I've a question… On the outside are some tiny white/straw-colored flecks (ignore darker flecks - this is some remaining Thyme from the cure). They do not penetrate the skin and I am not sure whether it's mold or salt coming out or fat or what. Thoughts? Likely safe? Thank you

-

I have received a wonderful gift from a lovely friend. A whole home cured, dried pig face. I call her Cameron. This will be used slowly over the winter. I'm dribbling thinking about the ears stir-fried with chilies Hunan style. The cheeks! The snout! I'm ecstatic. Snout I'm watching! I'll follow up with with how I use it, but for the moment I'm just content watching her watching me as she hangs in the wind on my balcony. It's love!

-

We made some salami a couple of months back using the pork from our berkshire pigs (which we rear on our orchard). We followed Hugh Fearnley-Whittingstall's advice in the River Cottage Cookbook, using LS25 as a starter and hung the sausages in our verandah, which is well aired and generally in shade except perhaps at sunset. We were going to take them down around about now, but have noticed the mould on them is not quite as it should be. They developed white mould about midway through the process of being hung, but this week we spotted other colours. We are uncertain how long they've been like that - maybe just a few days, potentially a few weeks. They are partially covered in a thin layer of white mould, but also in places grey/green and, more worryingly, with spots of black. The black seems to be a development of the white mould - you have spots of black surrounded by a circle of white. In addition, they have some moisture on them - which looks to me like condensation but appears slightly correlated with the black mould. (There appear to be spots of black where the condensation is - possibly just random coincidence.) I took a couple of pictures, below. Does anyone have any experience they could share on this? I've seen a lot of different opinions, ranging from "anything other than white is potentially deadly" to "you can just wipe it off with vinegar and it should be fine". Obviously I don't want to take risks with our health, but nor do I want to throw away 3 kilos of our produce. So I'm hoping someone will have useful insights! Thanks Josh

-

I've recently been reading (well, skipping around) my copy of Ruhlman & Polcyn's Charcuterie. My interest is primarily in dry cured products like prosciutto or bresaola. So I'd like to start a thread specifically about these variants. As my plans for building a curing chamber (and a proper place for it) take a back seat to other pressing home renovations, I'm in a kind of limbo between consumer and producer/both. But my imagination goes on and I keep finding new questions - among these are: 1) Commercial prosciutto: I've been doing taste tests with various super/specialty market prosciuttos and have found less differentiation than I would've expected. Even between a Walmart Del Duca and a Boar's Head imported Prosciutto di Parma, The Parma did take the edge in the judging, but not but not at a premium of $10/pound. Is actual prosciutto bought in Itally better? 2) The book Charcuterie seems to stop at describing the procedure for specfic things, That's fine, but what if I want to do something different (e,g, treat a pork loin as a breasaola)? Could science create a prosciutto in a shorter time by cutting it down into smaller pieces?

-

This afternoon I found a bag of sliced supermarket Genoa salami in my bedroom, where it had been several days without refrigeration. I was wondering where it went. It looked OK. Do you think it is safe to eat? Perhaps should I try to pasteurize it?

-

Is there anyone in the forum that can suggest me how to cook this kind of Portuguese sausage? Many thanks in advance!!!!

-

Where I live pork loin is often on sale for $2.00 or even less... Has anyone an opinion about using just pork loin for the meat along with the 20% pork fat? ? I've read that any meat can be used to make the cured salami... I'd like to hear from anyone before I try it...

-

Hi. I'm brand new to this site. I used to be on Chowhound but I see now that that site is a mess. I found this site and it looks pretty cool. The main reason I joined is I’m looking for recommendations for a restaurant to hold my wedding in March 2018. We were hoping maybe in Brooklyn but we are open to anything interesting. There will be 55-60 people and the ceremony will also be at the restaurant. I’m thinking of a brunch/early afternoon affair, most likely on a weekend. Would love to find a funky/old school/unique/charming type of place for my sweetheart. Inexpensive please! Thank you in advance!

- 7 replies

-

- 1

-

-

- Charcuterie

- Italian

-

(and 2 more)

Tagged with:

-

Hola egulleters! Those of you who know me know that I like to turn my hand at Charcuterie now and then. Nothing is more satisfying than breaking down a whole pig and turning it into delicious cured meats and sausages. I'm quite happy making a wide range of products but there's one thing that I just can't get right. Fresh Spanish cooking chorizo, in particular I want to try and recreate this wonderful stuff from Brindisa http://www.brindisa.com/store/fresh-chorizo-and-morcilla/all-fresh-chorizo-and-morcilla/brindisa-chorizo-picante/ They're wonderfully red, juicy and packed with deep pimenton flavour. Now when I make them I can get the flavour right but the texture is all wrong, very mealy, not at all juicy and the colour loses it's vibrancy too easily. What's the secret to them I wonder? Some kind of additive and/or food colouring? My recipe sees me mincing 2.3 kg fatty pork shoulder through a fine die, mixing with 80g pimenton, 50g salt, 30g sugar, 35g fresh garlic and stuffing into sheep casings. Here's a photo of them: I rest them overnight in the fridge before cooking with them. Maybe I should be putting some curing salt in there and hanging them for a couple of days? Does anyone have any experience making this kind of juicy fresh Spanish chorizo or even chistorra?

-

I'm thinking of dry-curing some duck prosciutto for the first time and I've been reading through a lot of blog posts about it. I've noticed that most people who don't have access to a humidity-controlled chamber end up with a very hard surface on the meat due to the overly-dry air. When curing regular prosciutto, most producers avoid this by covering the exposed meat with lard. Has anyone tried covering the exposed meat on the duck breasts with either lard or rendered duck fat?