KennethT

-

Posts

6,165 -

Joined

-

Last visited

Content Type

Profiles

Forums

Store

Help Articles

Posts posted by KennethT

-

-

22 minutes ago, BonVivant said:

Every. morning. Some dairy and multiple types of fruit.

Then I have to go out looking for new fruits. Visited another market today.

They know you want to take it home. Vacuum sealing the cheese is possible.

Gran Canaria produces some cow's milk cheeses, and some are mixed (cow's and goat's milk).

Tiles are rare here, unlike in Spain. This is a Portuguese shop.

One of my favourites (soursop that is).

Avocados the size of pomelo. (Also common in Chile)

I had hoped to find this fruit in Mexico but still haven't seen it after 3 trips. Finally...

Tiny avocados. A variety that can be eaten young.

You know you are on a (sub)tropical island when...

Ate it all on a bench. Being a fruit monster I have exceeded my limit. Didn't have room for anything else hours later. The egg fruit, my god, what an intense and rich fruit I've eve eaten. Had to pause half way. Very aromatic, impossibly rich. But, if I had to choose between canistel and mamey it would be mamey.

Went to this beer bar a bit later.

Industrial beers on tap and some international beers in bottles.

Back in our neighbourhood, we noticed a bar with a row of taps!

And some craft beer bottles in 2 fridges

A hah! They do have real craft beers here.

Finally, proper (NE)IPAs! Drank 2 rounds of double IPA and NEIPA. Had to make up for the lost time.

A car dealership has a few cars inside a traditional building (across the street from my lodging). No big car parks full of cars like in some countries.

The adverts and tourist brochures only show you the nice (photoshopped) places and things. But in reality the capital is a concrete jungle, dirty, crowded, polluted, many dogs and their crap, and is also "multicultural". Nothing nice to photograph, have to keep an eye on our things at all times. After La Palma it's like a punch in the face. Next time we go direct to a mountain village and stay there.

We have seen a bunch of places that sell takeaway food only so we decided to try some. Seafood paella, octopus salad, and abondigas.

Unfortunately after this day I could hardly eat due to the middle ear pain which also affected my jaw and swallowing. Plus a 24/7pounding headache and fevers.I'm sorry to hear about your ear infection troubles... I find that amoxicilin works very well and quickly.

-

1

1

-

-

6 hours ago, liuzhou said:

Almost unheard of. The ony one I've ever seen in China in the 28 years I've been here belongs to a Chinese returnee after some time in America, with her American husband and his wallet in tow.

None of the white goods stores have dishwashers. I guess they imported it from Hong Kong.

They could have brought it back with them from the US with a transformer. Lots of people moving overseas from the US bring their appliances with them.

-

2 hours ago, liuzhou said:

An evening of firsts.

1. First meal cooked in new apartment.

2. First meal cooked anywhere in a year. Since I got sick and broke my back, I've been relying on delivery meals. Although I was happy with most of them and found things I'd never had before I was aching to get back to the stove.

3. I set out to make my usual 'rou jia mo' but quickly realized I didn't have the large green chilli peppers I use for them. I had everything else. All I had in the vegetable drawer was okra, so I used it, livened it up with fresh red 'facing heaven chillies, garlic, garlic chives and coriander / cilantro, Shaoxing wine and a splash of soy sauce. Thinly sliced beef tenderloin made up the protein. Lapped into the appropriate bread and it's done. I made and ate three.

I think I invented a keeper!

So glad to see you back in the kitchen again!!! Hopefully to stay this time!

-

6

6

-

-

@rotuts I'm sure they're very tasty but the thought of Thai gyoza tickles my funny bone...

-

1

1

-

1

1

-

-

-

37 minutes ago, Tropicalsenior said:

Had no idea those were edible.

They're very fragrant - like a light floral smell. If you read my Penang foodblog here, it was a key ingredient in Asam Laksa - the sour fish noodle soup midway through the post. The flower goes great with sour flavors.

-

1

1

-

-

-

1 hour ago, Duvel said:

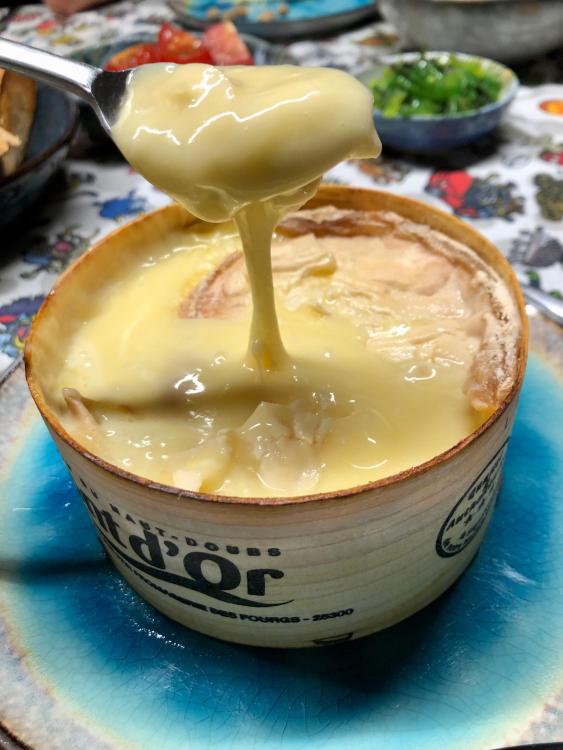

Om our drive back from our holidays in Spain we passed through the Franche-Comté area, and I picked up a raw milk Vacherin Mont d’Or.

Today I stuck some garlic cloves in, topped it up with a bit of white wine and popped it into the oven …

Served with good bread, cornichons, honey cukes, olives, some sausages, tomatoes, celery sticks, …

Soooo good 🤗

Fondue the easy way!!!

-

2

2

-

1

1

-

-

15 hours ago, BonVivant said:

We move on to another place next (the second part of the trip).

This means that this is not the end of this trip, no? I hope not - I always enjoy reading about your trips. Thanks for putting in the effort to document them so well!

-

2

2

-

-

2 hours ago, Tropicalsenior said:

If I remember their blurb correctly, this is a group of young Chinese American people that are trying to recreate the recipes that they remember from their childhood. Mostly by trial and error.

Andew Zimmern had (has?) a show on HBO where he would visit with various families making food together.... they were one of the first episodes.

-

1

1

-

1

1

-

-

2 hours ago, Tropicalsenior said:

If I remember their blurb correctly, this is a group of young Chinese American people that are trying to recreate the recipes that they remember from their childhood. Mostly by trial and error.

It's a Chinese American nuclear family (father, mother, two adult daughters) who lived in Beijing for a few years and are now back in NY, trying to recreate what they had while still in Beijing.

-

1

1

-

1

1

-

-

1 hour ago, Duvel said:

Hope you didn't catch what your wife/son had!

-

2

2

-

1

1

-

-

-

24 minutes ago, Dejah said:

Our little Chinese grocery store has been getting vacuum sealed packages of fresh lily bulbs in. I love this soup made with pork bones. Made chicken patties, a different kind of recipe, without any bread crumbs, etc as a binder. They were sloppy to work with, but turned out lovely! Perogies made by a good friends, cooked in air-fryer.

Went to Safeway for bananas, and their rotisserie chickens were just coming out of the oven! Chose potato wedges and creamy coleslaw for sides. Made a Japanese curry gravy with Glico cubes.Lots left over for sandwiches the next days.

Granddaughter, 9 and 11 year olds, came for supper last night: medium rare steaks and waffle fries. They like only raw vegetables!

For dessert, they had their first pomelo and loved it! That was followed by Chapman's Coffee Chips ice cream. These girls have healthy appetites. They ate from the time they walked in the door!

Were the lily bulbs fresh or frozen?

-

-

-

46 minutes ago, weinoo said:

From??? (Did you see that Dhamaka/Biryani Bol is now offering a meal kit for their biryani at home?)

This came from Bhatti Indian Grill in Curry Hill. I did see that Dhamaka started offering the Biryani to go/delivery that you heat at home. We were about to go away when they first introduced it but I'm considering it for one day soon. We do like ourselves some dum biryani.

46 minutes ago, weinoo said:Mulberry/Canal?

Yes.

-

-

1 hour ago, Shelby said:

I need to get to the Asian market. Are pea leaves the same a pea shoots? I love pea shoots.

Here they are but in other places, pea shoots looks like a week older than microgreens. In my local HMart, they're called Bean leaves or something like that.

-

1

1

-

-

-

-

In don't usually post take out meals but I was discussing this with @liuzhou over here which got me in the mood for some....

Supposed Hunan bamboo shoots with pork underneath are rice noodles and it came with a side of broth to add to make soup noodles. Also hiding are more green and red chillies. It was quite spicy tonight, my nose was running for a good 20 minutes after. I'm sure something else will be running tomorrow morning... 🤣

ETA I ordered this "medium" which is 2 out of 4

-

5

5

-

1

1

-

5

5

-

-

@Shelby First, looking at the most recent photo, I'd say the tomato plant needs more light - the internode space (vertical space between the branches) looks pretty big. Like others have said, if it's an indeterminant plant (like most heirlooms), topping the plant will NOT help. Don't ask me how I know... ok, I'll tell you - I did it, and the tomato plant became this GIANT bush that took over my apartment. Pro tomato greenhouses train the plants to grow up a strong supported by the greenhouse ceiling. As the plant gets taller, they let out more string which causes the plant to lean. You can lower the plant a few inches a day to make sure you don't snap the stem. Over time, all the lower leaves on the main stem will die off leaving only maybe 5 feet of leaves, but tomatoes will actually form on the long main stem. Rather than leaning the plant straight as is done in the greenhouses (they've got lots of space) you can actually slowly wind it around the pot its planted in in a spiral so it doesn't take any extra space. Indeterminant tomato plants can get to be 30 feet long and will keep producing for a year, even though they start to slow production after 9-10 months or so.

If it's determinant (most hybrids), then you can top it but it probably won't keep growing vegetatively after 5-6 feet or so.

-

1

1

-

-

Dinner 2024

in Cooking

Posted

Sichuan twice cooked mahi mahi