-

Posts

518 -

Joined

-

Last visited

Content Type

Profiles

Forums

Store

Help Articles

Everything posted by PedroG

-

Thank you, Nathan, for all you did for the community and for your plausible explanations. Do I get something wrong, or are the tests you mention in contrast to what you write in your book? To answer the question "boiling or crushing", I suggest the following experiment with three similar cuts of chicken breast and/or fish: Expose to maximum vacuum (99%+30sec), do not seal, release vacuum, seal at 80% vacuum. -> boiling, no crushing. Seal at 99%+30sec vacuum -> boiling and crushing Seal at 80% vacuum -> no boiling, no crushing To prevent floating with 80% vacuum sealing, either use an edge sealer for 80% vacuum, or try to squeeze most air out of the bag before sealing in the chamber sealer as I suggested upthread. Cook chicken at 63°C to pasteurizing conditions according to thickness, or fish at 48°C as Dave Arnold did. Check liquid loss by aspect and by weighing. Check organoleptic outcome by blind testing. As I have only an edge sealer, I can't contribute to these experiments.

-

See upthread

-

The vacuum level dilemma with chamber sealers for sous vide cooking Edge sealers suck all air out of the bag before sealing, tightly fitting the bag to the food; so even with low vacuum levels, there is virtually no air left in the bag, except for some surface irregularities of the food to which the plastic may not have been snugly fitted. Maximum vacuum levels achieved by edge sealers (80-90%) will not damage food by cold boiling and/or compression (see Dave Arnold's "Boring but useful technical post: vacuum machines affect the texture of your meat" and Modernist Cuisine page 2•213 "Boiling not Crushing"). In contrast, chamber sealers suck the air out of the bag and its surrounding, then seal, and the bag will only be fitted tightly to the food after releasing the vacuum from the chamber. To fit the bag snugly to the food, vacuum levels of 99% to 99.9% are applied. These vacuum levels may damage delicate food like fish or poultry. Reducing the vacuum level in a chamber sealer to e.g. 80% may leave some air in the bag causing floating and poor heat transmission: if the initial air volume between food and bag was e.g. 200ml, after sealing in an 80% vacuum there will be 40ml of air (that’s a jigger!) left in the bag. If there is no edge sealer at hand for sealing delicate food, a Ziploc bag may be preferable to the chamber sealer. A way out with a chamber sealer might be using a sealed bag of water to weigh down the bag to be sealed and eventually a second sealed bag of water below the bag to be sealed, thus displacing as much air as possible out of the bag before sealing.

-

I did it again (four eggs of 143mm circumference, 75°C / 16 minutes), see upthread. The result was perfect, but one of the eggs must have had a slight crack that had gone unnoticed. It was just a little bit of egg-white that escaped, but what a mess! Cleaning the polycarbonate container and the FreshMealsMagic took me considerably more than half an hour. In the future I will do eggs only in my SVM-controlled stockpot without a circulating pump so eventual cleaning would be easier.

-

Overpressure / underpressure (a geek's Mulligan stew) The posts in this topic on pressure cooking made me reactivate my old Kuhn Rikon Duromatic. I had these vegetables at hand: I had planned to make a stew with a cut of brisket I had previously cooked sous vide ("underpressure") 55.5°C/48h. So I decided to cook the stew under overpressure. Here's the mise-en-place: I sautéed the onions in butter, added the stalk celery, deglazed with 1 liter of vegetable stock plus the pasteurized gravy from a previous brisket, added the rest of the vegetables and cooked 120°C / 7 minutes. Then I let the stew cool down to avoid boiling the medium-rare brisket (reheated SV 55°C/3h), which I cut into cubes small enough to expose more surface to the Maillard reaction but large enough that 2 minutes of stir-frying in smoking hot rice bran oil would not cook them well-done: . After stir-frying I let the brisket cubes rest for a moment before adding them to the stew. In fact, besides being spoon-tender and succulent, they had remained pink inside. SWAMBO found it delicious, me too.

-

Rural, near Zurich / Switzerland. Home cook, interested in the "why" that logically leads to the "how to". Special interest in cooking sous vide.

-

I always warm my plates using a Solis plate warmer. The microwave trick is very smart, but my plates have gold rims and would spark in the microwave and get ugly black spots. Meat and fish cooked sous vide are not very hot, so a hot plate is mandatory.

-

"Modernist Cuisine" by Myhrvold, Young & Bilet (Part 3)

PedroG replied to a topic in Cookbooks & References

A few months ago I would have agreed, but now with this trick and some practice it is feasible, as confirmed by drago. With the usual 80% vacuum of edge sealers, boiling point of water is about 60°C/140°F, so cooling before sealing is not as important as with chamber sealers. -

Can you specify what equipment you have? What's the problem?

-

Brisket „Stroganoff“ Sous Vide With Mixed Mushrooms The perfect "perfect egg" Ossobuco sous vide Olla podrida sous vide Marinated brisket Enjoy!

-

Hi Peter, before buying a digital thermometer, you might tread this. To my knowledge one of the least expensive precision thermometers is the Greisinger GTH 175/PT (resolution 0.1°C, accuracy ±0.25°C). You get it at www.conrad.at, you might prefer the version GTH-175PT-K which you can use as a core temperature meter in the oven (up to 250°C) as well as for calibrating your SV-rig. Beware cheap "junk" thermometers, they may be miscalibrated by several degrees.

-

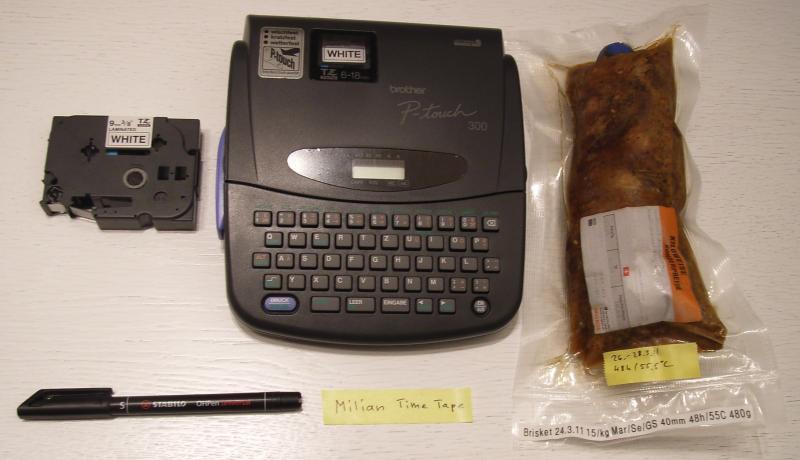

Thanks, Peter. I was hoping for the labels that can be hand-written with I guess a permanent marker. Hi Anna, usually I label my SV bags with a Brother P-Touch with laminated labelling tape. When I am lazy or in a hurry, I use a Stabilo OHPen permanent marker on Milian Time Tape, and sometimes I just write directly on the SV-bag with the OHPen. I get Milian Time Tape from Milian Switzerland; for Canada you may order at Milian USA. BTW in the picture you see a cut of brisket after 48h/55.5°C, and the original supermarket-label which I vacuumed between the cling-film and the bag just got a little bit moist, but the liquid from the meat remained inside the cling-film. Regards Pedro

-

Nathan's table is here, but if you do not have precise temperature control, I would rely on the equilibrium temperature method where you have only one critical parameter (temperature) and time is not critical. Temperature swings in the water bath will be attenuated within the meat by the limited heat conductivity of the meat, so if your water bath oscillates ±2°C or so around your desired core temperature, you will achieve your desired doneness.

-

I guess your tenderloin is near cylindrical, so use this table to determine heating time. If you can keep your water bath temperature between 51-55°C, you should be fine. Post-sear the whole roast and/or sear each individual steak to give more crust. Enjoy!

-

"Modernist Cuisine" by Myhrvold, Young & Bilet (Part 2)

PedroG replied to a topic in Cookbooks & References

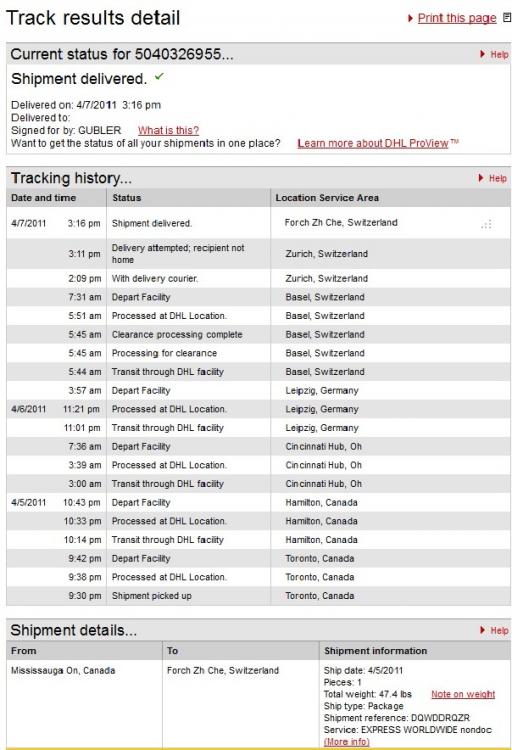

Anna, I miss Kerry's photographs! Well, I couldn't resist either to take a few pictures. I had not noticed our wireless doorbell was out of battery power (doh!), but luckily I looked out of the window just at the right moment and saw the DHL guy typing "recipient not home" into his machine (one minute later he would have been gone!): Heavy! 625 bucks! This should stand the "Philips test 10" (free fall from 10 meters; I did not verify!): The kitchen manual: The perspex box wrapped in paper: Here it is: Other cookbooks look pretty tiny! -

Equilibrium brining On page 3·154 ff the principle of equilibrium temperature cooking we use in sous vide is applied to brining. In contrast to measuring final core temperature in sous vide cooking with a thermometer, the end point in equilibrium brining can be determined by measuring salinity with an "inexpensive salinity meter". Has anyone tried this? Where did you get a salinity meter? At what price? Can you recommend it?

-

"Modernist Cuisine" by Myhrvold, Young & Bilet (Part 2)

PedroG replied to a topic in Cookbooks & References

coquus and others in the same topic. -

"Modernist Cuisine" by Myhrvold, Young & Bilet (Part 2)

PedroG replied to a topic in Cookbooks & References

Hi Peter, mine arrived, see below. The 5 books are 14.1 kg, the transparent box is 2.6 kg, and the kitchen manual is 966g. The total package was 47.4 lbs. or 21.27 kg. I really hope for you they converted lbs. to kgs and then again which might explain 10kg. -

Hanger steak My first experience with diaphragm was not bad, but not "the ultimate treat". Now the same supermarket had hanger steak (cuts of about 400g, thickness 35mm) on the self-service shelf at a price 1/6 of tenderloin or 2/3 of brisket, so I gave it another try. Marinated two days at 1°C, 48h/55.5°C (batch cooking together with three cuts of brisket), chilled quickly and 9 days later reheated 2¼h/55°C, seared in smoking hot rice bran oil, it came out fork-tender, with a nice dark crust and perfectly red inside, very tasty and succulent. A few thick tendons were not gelatinized as I experienced earlier with enzymatic tenderization. I hope I can repeat this experience in the future. I was so excited I forgot to take a picture of the finished dish, so here are only the pictures before vacuum-sealing:

-

According to Nathan's table you can cook a 150mm slab at 65°C bath temperature for 3h53' to a core temperature of 50.5°C which during rest time of 58' will rise to a final core temperature of 54.4°C, and you are still safe without the heat pipe thing which I suggested rather for fun as a theoretical possibiliy and not meaning you really should do that.

-

"Modernist Cuisine" by Myhrvold, Young & Bilet (Part 2)

PedroG replied to a topic in Cookbooks & References

Just got an e-mail from amazon.ca, shipped April 5th, estimated delivery in Switzerland April 11th. Ordered in October. -

Hi Anna, just to illustrate what Douglas explained, see the graphs in my wikiGullet article, and the discussion in a late topic. The difficulty in calculating cooking/pasteurizing times from frozen is caused by the chaotic behavior of heat conductivity during phase change (i.e. the transition from ice to water). We always refer to danger zone and pathogens but not to spoilage germs. I quote from my above-mentioned article: "Thawing in cold water (0°C) would shorten the time in the "danger zone" but prolong the time in the "spoilage zone", as spoilage bacteria begin to multiply at 23°F/–5°C."

-

vengroff, that's awesome! Would you mind programming this for a common Windows-PC (Excel-sheet)? Or a Windows-Mobile-PDA? Thanks Pedro

-

See comments

-

Hi Pedro! Thanks for asking and offering a suggestion. So, I've cooked salmon before using the temp/times from Doug's book before, but have never frozen them after cooking. I can't remember what was in the bag with the salmon, but I believe very little. Most likely only either some butter or a splash or two of olive oil. This was sushi grade Norwegian salmon that was typical of what they sell here in the states; about an 1.5 inches in the middle tapering down to "very thin" on both ends (no skin). I sealed the salmon using the Sous Vide Supreme vacuum system - most likely running on automatic. In looking in my "Sous Vide for the Home Cook" book; I would have cooked them for about 45 minutes @ 140. I would have then quick chilled them in a pot of icewater for 30-40 minutes and then put them in the freezer. On the reheat, I would have set my bath (Sous Vide Supreme) for 130 and placed the frozen salmon in for approx. 1.5 hours. I don't recall ever having the problem when I simply cooked the salmon and then ate it right away, but I never froze it before. Once again, since my wife LOVES salmon, it would be uber cool to be able to buy a large portion and cook/quick chill it and then freeze it. In response to another reponse here, my thoughts on why I don't simply buy the salmon and vaccuum and freeze it raw was that I thought I read the the quality would be higher by cooking it first. For example, a cooked piece of salmon frozen would be in better shape and taste better on the reheat 3 weeks from freezing than a raw piece of salmon being vacuum packed and froze. Is this a misunderstanding on my part? Which is better? Freezing raw product or freezing cooked/quick chill product. Specifically salmon. Thanks all! Todd in Chicago P.S. My VP112 just arrived today! I can't wait to check it out tomorrow! Hi Todd, in my experience, salmon gets falling apart when cooked for substantially more than the minimum required heating time. Heat-freeze-reheat more than doubles your cooking time. After cooking fish sous vide, you will notice a layer of albumin that has leached out of the fish and coagulated and which you would dab off before searing; this might have glued to the plastic during freezing. So I would recommend to buy your fish frozen. Frozen fish is fresher than fresh fish as it is frozen immediately after catching, and I guess deterioration of quality be freezing is less in professional freezing than in home freezing, and furthermore you are safe from parasites like Anisakis after professional freezing. As a cooking temperature for salmon, I prefer about 45-46°C and post-searing in smoking hot rice bran oil or grape seed oil, so the center remains a little bit translucent. P.S. Be happy with your new Vacmaster VP112, but be careful not to apply more than 90% vacuum to fish, or else it may get mushy, see wikiGullet.