-

Posts

518 -

Joined

-

Last visited

Content Type

Profiles

Forums

Store

Help Articles

Everything posted by PedroG

-

boudin noir, welcome in the community of sous vide cooks! You don't have to wait until you can afford an immersion circulator, you might start like I did. When it comes to long time cooking, a PID controller (DIY or SVM) and a bucket heater (or FreshMealsMagic) will do, eventually enhanced by an aquarium bubbler (supporting higher temperatures than fountain pumps). Have fun! And don't be scared by cholesterol in food, as 70% of your circulating cholesterol comes from your liver, not from the food.

-

I think sous vide cooks are (or should be) the kind of people not just asking for the "how to" (recipes), but for the "why", i.e. curious cooks reading books of Harold McGee, Nathan Myhrvold, and the like. This knowledge can significantly help cooking better with traditional methods as well, e.g. knowing the temperature ranges and actions of the tenderizing enzymes calpaines, cathepsines and collagenases, which makes us understand Harold McGee's "Guidelines for Succulent Braises and Stews" which I cited in the old sous vide topic. My personal experience with tough meat 48h/55oC sous vide is that some thick tendons may escape enzymatic denaturation, as collagenase sits in the sarcoplasm (the cytoplasm of muscle cells) and has a long way to travel into thick tendons. A workaround might be cooking below 60oC until the thin collagen sheaths (endomysium and perimysium) surrounding the muscle fibers have been enzymatically hydrolysed by collagenases, thus avoiding contraction of intact collagen sheaths at temperatures above 60oC, squeezing juices out of the muscle cells. Subsequent heating to temperatures between 75oC and 80oC will hydrolyse thick tendons and fasciae thermally.

-

Sorry, boudin noir, I hanged you - yesterday at 07:30 AM - in the water bath, together with liverwurst, green bacon and sauerkraut, set the temperature to 80oC and let you simmer until lunch time. Then I just pulled you out of the water, served the contents of the bag on warmed plates, making up a nice little metzgete, and ate you up with relish, leaving only the skin. Even the bacon's rind was completely converted to tasty gelatin.

-

Welcome to the eGullet forums, boudin noir! You could do the community a great favor by explaining how one can do better with traditional methods: Cooking tough meat fork-tender yet medium-rare Cooking eggs with a set white (neither runny nor rubbery) and a creamy yolk We are eagerly awaiting your explanations.

-

Justin, for how long did you marinate?

-

I think your new probe is more responsive. The plastic covered one is also shielded inside. I don't think it would be a problem to shorten it. Instead of guessing you might determine the thermal time constants of your probes like this: Determining thermal time constants of temperature sensors can be done by changing ambient temperature from e.g. 55oC (PID-controlled water bath) to 0oC (ice water stirred with a milk frother). The thermal time constant (tau) is the time to change by 63.2% (T) of the temperature difference: T = 0.632 * T2 + 0.368 * T1 (20.24oC in the above example) So just note starting time at 55oC and look for the time when 20.24oC is reached, the difference is your thermal time constant. Inappropriate relation of thermal time constant and cycle time of the PID-controller may lead to aliasing. Looking forward to your results (they may be counter-intuitive).

-

I never did an organoleptic comparison of non-frozen-SV versus frozen-thawed-SV versus frozen-SV. Anyone else?

-

No problem directly from freezer to the SV bath. See Core temperature development in frozen versus refrigerated meat cooked sous vide

-

I used it up to 80oC without any problems, and I guess 85oC will not melt the bubble wrap. Alternatively, use a tall beverage cooler. Edit: The melting point for average, commercial, low-density polyethylene is typically 105 to 115oC (221 to 239oF).

-

Very funny, but this would really be an awful lot of trouble. Cooking in-shell eggs in a 75oC water bath for about a quarter of an hour is fast and simple and straightforward.

-

I can just confirm what Kerry said. I have no problem with the FMM's polycarbonate container not being insulated, although steady state energy consumption could be reduced from 100W to 40W by insulation with bubble wrap. Without bubble wrap the pot is transparent and you see what happens inside, and with more heat loss recovery from temperature overshoot is faster, making tuning even easier. Immersion heaters (SVP, FMM or simple bucket heater) have less thermal inertia than rice cookers and other cookers with the heating element outside the vessel wall; this makes (PID-)tuning easier, see my last post in the old SV topic. With SVM plus Marshalltown plus an aquarium bubbler or fountain pump you are within your 200$ limit. A simpler PID-controller may do for an immersion heater system, although SVM has a more sophisticated Ar function than usual PID-controllers (see PID tuning guide), making tuning of more inert systems like rice cookers easier. But I also fully agree some tinkering makes things more interesting for a geek. Be aware that fountain pumps are rated 35oC, if you are lucky they may tolerate 60oC, but at higher temperatures they melt, so you might opt for a bubbler (use the air stone as a weight only, but cut one or two sideward holes in the tube just above the stone, larger bubbles rise faster resulting in more vigorous circulation and less evaporation. Edit: workaround to write 35oC instead of 35°C.

-

Maybe this would make measuring easier and faster: Download here: PedroGs Egg cooking ruler.pdf (Any suggestions for improvement?)

-

I just saw an "as seen on tv" ad for this, and it's now selling for $20, which includes a vacuum sealer. Obviously, I'm not expecting this to be on par with my SVS, but I'm having a hard time thinking of a reason not to try it out. If it works reasonably well, I'd use at as a sort of portable "road" sv setup. $19.95 is for a 30-day-trial, then it's 3 payments of $39.95 if you want to keep it. Totalling to $140 instead of $200. Looking forward to someone reporting on its temperature accuracy and stability, as well as the internal dimensions of the bath.

-

I never noticed any smell from SV bags; I use vacuum bags (rolls) from MagicVac which are multilayer PA/PE (polyamide as an oxygen and aroma barrier and polyethylene as a water vapor barrier and sealing layer). I routinely wrap spiced and marinated meat in cling wrap before bagging, keeping the sealing region of the bag clean; after 48h cooking, the gravy remains within the cling film. My Ziploc bags (which I use rarely) are PE (polyethylene) only; PE is known to be permeable to oxygen, carbon dioxide and flavors. So some smell with Ziploc bags is not surprising.

-

To keep the bags in place and vertical, place a glass bead or glass rod or marble in the bag's bottom and suspend the bags on a skewer. To make a suitable skewer, use 3mm or 4mm SS wire from a hardware store or a farming supplies store, bend to fit your container, and sharpen one end to facilitate piercing the bag. Suspension also facilitates retrieval of the bag without scalding your hands.

-

You might precook many eggs at 75°C for the required time, then either transfer to your 60°C bath until served, or chill for later use and reheat in the 60°C bath.

-

Did you try this method, i.e. 75°C for a time depending on circumference, see here and here and here?

-

I admit to being anal but since the water often smells after I have cooked something in it, despite the vacuum bags, I am not willing to let it sit for days at any temperature. If I empty it immediately and dry it out and refill with hot tap water next time I want to use it, I don't find it takes more than 15 minutes to reach temperature. Your mileage may vary but I think there are enough risky things with SV that this is not something I am willing to compromise on. I never noticed any smell in the water bath, and I see no problem changing the water only every now and then. I use distilled water (i.e. the condensed water from the air dehumidifier in the cellar), thus avoiding limescale as well as growth of most bacteria. Every 48h/55°C cooking should theoretically reduce eventual pathogenic bacteria by something like 150D. For additional safety, the water could be heated to e.g. 80°C for an hour between rounds of cooking.

-

When the superficial layer contracts by cooking, the cut has to change its shape towards a cylinder or even sphere in order to encompass the same volume (like a balloon). So if your chicken breast thickened from 45 to 55mm, its width had to get smaller accordingly, so your cut approached cylindrical shape to some degree, speeding up heat transfer to the center. Maybe our mathematician can tell you if this fully compensates for increased thickness.

-

Up to 30mm, meat heating times and poultry pasteurization times do not differ much, but with thicker cuts, poultry cooked 63°C is pasteurized before it reaches 62.5°C core temperature, so if you want 62.5°C throughout, you have to pick whatever time (heating or pasteurizing) is longer, and if you just want safety, you may stay with pasteurization time and accept the core temperature to be eventually lower (which may be desirable, less liquid loss). Heating time tables may be quite different depending on the underlying assumptions. Douglas calculated all tables up to version 0.4h of his guide with thermal diffusivity α = 0.995×10-7 m2/s, whereas in the new version 0.4i he used thermal diffusivity α = 1.4×10-7 m2/s for heating beef, α = 1.11×10-7 m2/s for pasteurizing beef and α = 1.08×10-7 m2/s for pasteurizing poultry. Moreover he used a geometric factor β=0.28 for all thicknesses in the poultry pasteurization table, whereas in the beef pasteurization table, he used β=0 (corresponding to an infinite slab) up to 30mm thickness and β=0.28 (corresponding to a 2:3:5 cuboid) above 30mm. These changes are reflected in the quite different times in my old thickness ruler and the new thickness ruler.

-

Be aware of the text to Douglas' table 2.2: So heating times are practically the same for heating from 5°C to 55°C or 63°C. From Douglas' table 4.1, pasteurization times for poultry I picked 63°C for the ruler because at 63°C minimal heating time and pasteurization time are about the same, as a compromise to avoid very long pasteurization times which might lead to mushiness and too high core temperatures leading to dryness and toughness. And have a look at the wikiGullet article Importance of temperature control on pasteurizing times: When cooking to higher core temperatures, pasteurization is achieved before final core temperature is reached.

-

I would try 55C for 48 hours. It should come out juicy and medium rare. Sprinkle it with salt and pepper, add a 6-10 garlic cloves and a sprig or two of thyme wrapped in a paper towel. This will prevent the garlic and thyme from overpowering the flavor of the meat. I agree with 55°C/48h if you like your meat as pink as possible, otherwise at 58.5°C collagenase works faster, but above 60°C collagenase gets inactivated and collagen starts shrinking and squeezing liquid out of the muscle cells. So my advice is to cook tough meat either between 55°C and 59°C (collagen gets denatured enzymatically) or braise traditionally (collagen gets denatured thermally) at 78°C (not above 80°C where actin coagulates and cell contents are densely compacted, resulting in a texture like cardboard or shoe leather). See Harold McGee, On Food and Cooking, page 152. See also paulpegg's experience with leg of lamb upthread.

-

The idea of the plastic tree caliper is brilliant, but unfortunately the resolution of 1cm is not exactly brilliant. Still simpler is the precursor of my ruler I posted 26 February 2010:

-

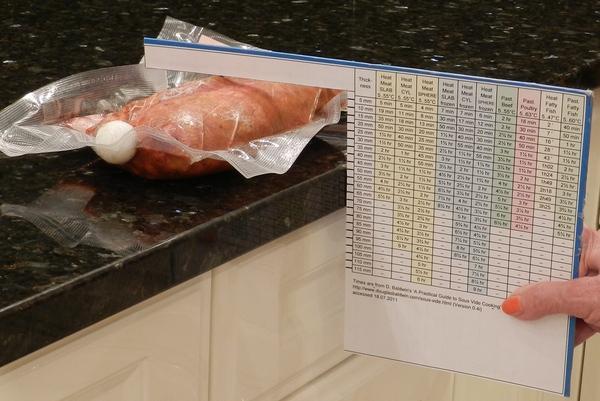

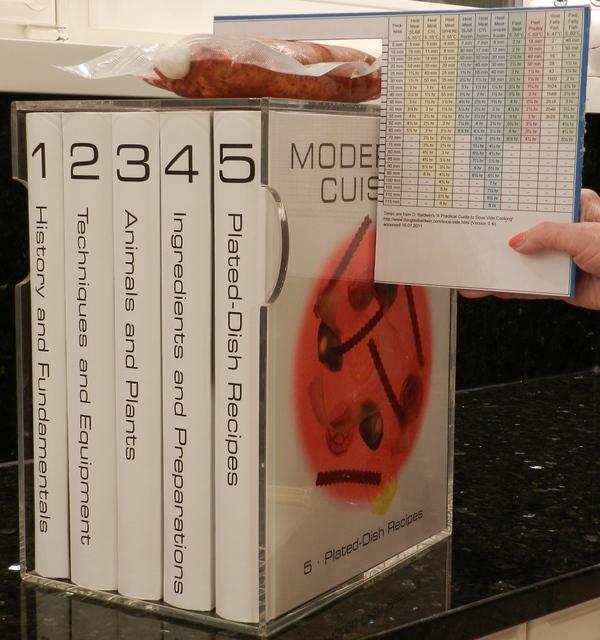

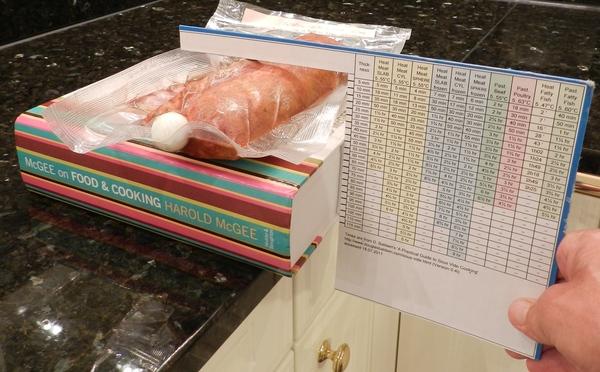

When using my ruler, calipers are not necessary anyway, a kitchen table with a rectangular border will do to adjust the ruler exactly vertical/horizontal: If your table has rounded borders, just use MC: If you do not have MC at hand, McGee will do:

-

Jaws are too short (1-9/16").