We're hunkered down in a wind and dust storm right now; it's a good time to backtrack to an earlier stop.

Palmetto Island State Park, in the heart of Louisiana's Cajun country, is a nice new state park set up for RV's as well as tent-camping and backpacking folks. There are paths through the (very dense) palmettos with signs to help one learn how to distinguish poison ivy from Virginia creeper. They have a Dutch Oven cooking festival every month that we still haven't managed to hit, but someday we may make it.

We walked into the registration station. "How many nights?" asked the registrar. We answered as one voice:

"One," said my darling.

"Three," said I.

We looked at each other. Apparently he hadn't registered my discussion about a side trip I wanted to make. We compromised at two.

We set out the next day, our destination only 10 or 15 miles as the crow flies but 30 miles away by road due to the low land, rivers and channels that jigsaw the land. Our GPS took us around Robin Hood's barn, supposedly by the most direct route - which then required considerable backtracking due to road closures. The benefit was that we saw interesting scenery along the way: sugar cane fields in every possible stage of cultivation or harvest,

and a lot of water. Shallow waters abounded with herons and egrets.

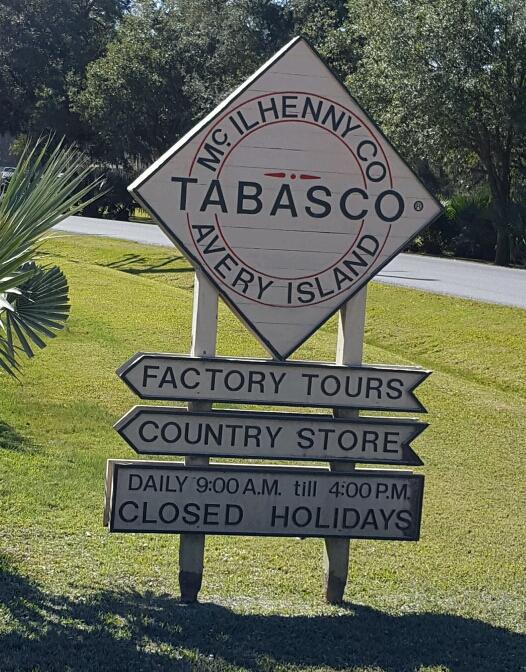

45 road miles later we arrived at our destination.

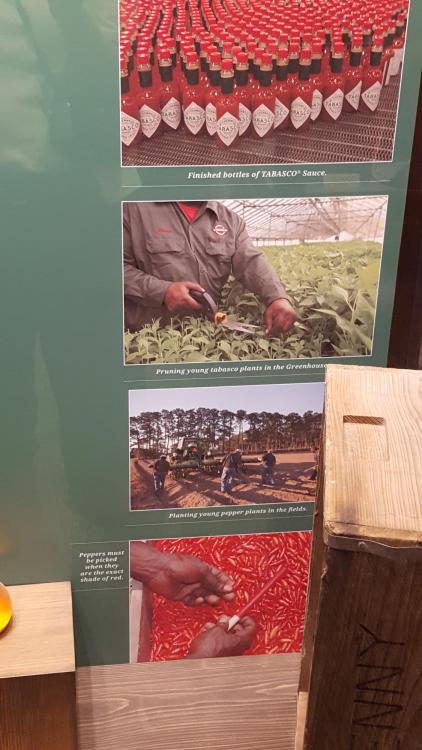

The factory tours are self-guided. You walk at your own pace, see what you want to see for as long as you want to look, and snap as many photos as you wish. (You can pay for a guided tour with a docent, but we chose not to.) The tour begins with a museum that gives the history of the company and the McIlhenny family. It also gives an overview of process, from cultivation through the bottling. I did not know before this trip that the peppers in question are grown in multiple countries on small farms. The company states that they work with their farmers to ensure sustainable practices and fair prices.

In the bottom image above, the worker is holding a red stick that is used as the ripeness gauge for the tabasco peppers. We saw that color a lot - even in a room with one wall painted that particular red.

TABASCOTM sauce has 3 ingredients as shown here: salt, vinegar, and pepper mash. Time, the process and the equipment take care of the rest.

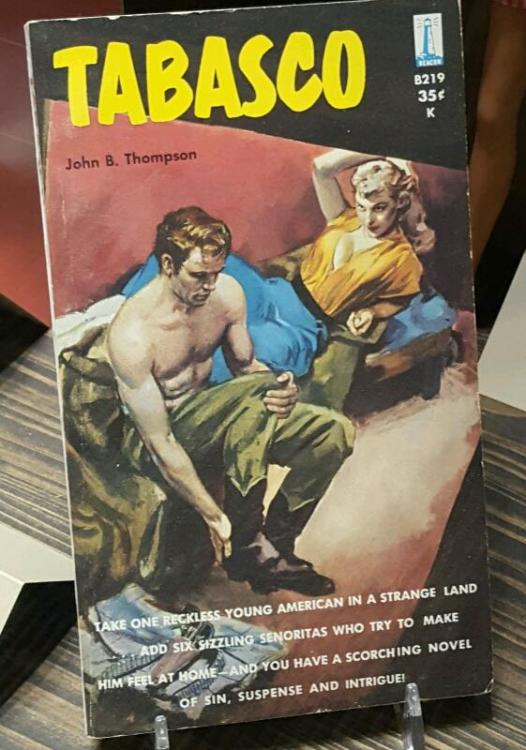

In addition to family information and artifacts, they had amusing cultural displays.

The next stop is the greenhouse, where more information is given about the peppers that they cultivate for their sauces. One distinguishing characteristic of the tabasco pepper is that the fruits grow upward...or so the sign said. It looked to us as though some drooped slightly, but they didn't hang down the way the habañeros and jalapeños did.

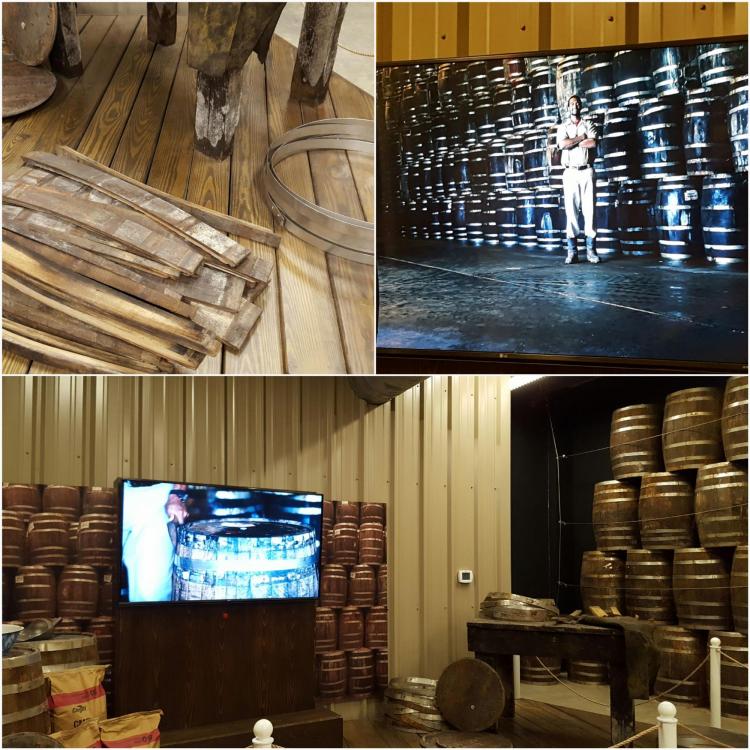

The cooperage had a fascinating short video with one of their coopers explaining his work, and with a number of barrels on display. I've forgotten the source of their white oak barrels, but the barrels are disassembled, scraped inside, and then rebanded with stainless steel rings instead of the original metal (zinc? tin?) bands before being put to use for the TABASCOTM process.

The peppers are mashed. (I think salt is added at this point, but I may be misremembering.) The mash is put in barrels to ferment - for 3 years, for the basic sauce. The barrel tops are covered with a couple of inches of salt to keep out impurities, and the barrels are stored by lot in a fermentation building. The building is closed with a grate that allows air to pass through freely while keeping out unauthorized visitors. I think the powerful odor would keep out most visitors, but the local bears might find it appealing.

After the necessary aging, and after quality control tests, the fermented mash is strained and added to mixing vats with vinegar and perhaps salt. The vat batches are checked for quality, and the mix sits and brews for some weeks before being bottled. This was the stage at which the operation became clearly quite high-tech: with speed control and temperature control and very careful sanitation control. As someone who used to work in industrial process control I loved being able to see so much, at my leisure. This is the view of the vats from the ground floor. From upstairs, you can see the open vats with controllers, piping, and workers going about their business along catwalks. You can also press a button to turn on a fan so you can smell the room. The aroma is much more mellow than in the fermentation area.

The bottling plant looks efficient and well-controlled. There were 4 lines running 4 different sauce products. Machines did the bottling and process monitoring, and humans monitored the equipment. At one point some bottles went awry - it wasn't clear to us what happened - and a worker rounded them up off the belt for, we were told, rebottling the sauce in question. (I don't know whether I believe that, but it's the answer we were given.) The monitoring and quality control were impressive.

I was just as impressed by the company's apparent interest in worker safety and esprit de corp. Those workers were kept informed about what they were making, how well they were making it, and where the product was going. In addition, safety notices abounded. My former employer had a motto: "Whatever you do, do it safely. Someone expects you home tonight." This plant had that feel. If it was all only PR, they made a convincing show of it.

The last stage of quality control is a tasting panel that convenes every few weeks and samples the product. ![]() I'm trying to imagine doing that, year in and year out: first, whether my taste buds could survive and second, keeping a taste-standard in mind. It would be like perfect pitch for the taste buds. I couldn't do that. Apparently some people can.

I'm trying to imagine doing that, year in and year out: first, whether my taste buds could survive and second, keeping a taste-standard in mind. It would be like perfect pitch for the taste buds. I couldn't do that. Apparently some people can.

This post is already long. I'll finish in another installment.

.thumb.jpg.d4da2fd9792741b4100162870769497d.jpg)

.thumb.jpg.403b8a928e1824aacbb20317d5ed0834.jpg)