boilsover

-

Posts

918 -

Joined

-

Last visited

Content Type

Profiles

Forums

Store

Help Articles

Posts posted by boilsover

-

-

On 8/8/2016 at 9:21 PM, Thanks for the Crepes said:

I thought this was such a great idea, I just tried it on my meat and veggie boards. At first I thought the peroxide may have gone inactive, but it's in date. It also reacted when in touched it with my fingers that had recently been washed with soap and water. Then I poured some on the sponge, and it went crazy and the sponge got warm.

So, apparently my current sterilization procedures are working fine for the cutting boards, but I gotta work on the sponge procedures. The one that reacted so strongly has been rotated down for wiping up floor spills, and replaced with a new one.

ETA: When I exposed the new sponge to the peroxide on the boards, it did not react, so it wasn't reacting with the cellulose in the old one, but something more sinister. Well, good to know, and a good test to see how clean your sponge is too. I always wash out the sinks with a sponge and hot soapy water as the last step of cleaning the kitchen and rinse everything well in hot water. Then I prop up the sponge against the backsplash so it'll dry out thoroughly. Clearly, this isn't enough. I guess I have been lucky, but I need to do better here.

It IS a great idea. Hydrogen peroxide is a very versatile and economic chemical to keep in your household. A neighbor recently gave me a gallon of 35% concentrate from here: http://purehealthdiscounts.com/

The key to HP use is its dilution. 35% dilutes down to these proportions

Use Mix Ratio

3% Conversion 1 ounce per 11 ounces water 1:11

Hand Wash 1 ounce per pint water 1:16

General Sanitizing 1 cup per 1 gallon water 1:16

Laundry 1 cup per load --

Vegetable and Meat Wash 1/8 cup per 1-gallon water 1:128

Plant Watering 1/2 ounce per 1-gallon 1:256

I keep a spray bottle of 1:16 around all the time or cutting boards. That strength is also amazing for removing red wine stains, pet accidents, etc..

-

1

1

-

-

Looks very nice.

But $21 for a rubber spatula? That's more than I paid last week for a complete Vitamix Super 3600.

-

1

1

-

-

Ceiling Velcro has its own unique appeal and look...

-

3

3

-

-

Wow! Congratulations. What material are the countertops?

-

My 1905 Monarch solid-fuel and 1948 GE Airliner aren't junk ranges. Neither is my 1960 Frigidaire refrigerator or my International Harvester chest freezer. All are likely to outlast me.

-

3

3

-

-

Unused Mauviel 4.9Q beating bowl for $7 at a garage sale this weekend. Marked Williams-Sonoma.

-

4

4

-

-

Return it if you can, and avoid anything with Stewart's name on it.

If you want a poly board, get a Sani-Tuff or the like.

-

On 5/23/2016 at 4:59 PM, Tere said:

Is there any way I could get to a basic regime? I can read Japanese and can figure out I think what the bits are for.

Yes. I recommend finding a really good pro sharpener who offers classes. For instance, Bob Kramer taught Bob Tate here in Seattle, and he teaches classes to mortals.

My dad was a butcher, and I bladesmith as a hobby, so I know sharp. But either you have the touch, or you don't. Despite having a basement full of all the $$ and $$$ stones, belt grinders, microtome parphenalia, etc., I mostly don't have it. An hour with a skilled pro sharpener should determine if you do. If so, knock yourself out. If not, pay the pro to do it once a year. No powered wheels like Chef's Choice...

-

1

1

-

-

3 hours ago, palo said:

Nope. Only 0.5 mm of the good stuff. But it's better than the "copper" nonstick on the infomercial channels...

-

On 1/17/2016 at 7:27 AM, rotuts said:

you can get 3 mm , perhaps 3.5 mm SS lined pots if thats important to you

Hi:

I'd like to know where. In all my obsessive scrounging, I've seen fewer than 10, 3mm bimetal pans--all vintage and predating Falk's patent. Never a 3.5mm. If you know where they can be had new, I'm all ears.

Thanks.

-

10 hours ago, paulraphael said:

All the clad copper pans I've seen use three rivets. Not that two wouldn't be just fine, but that's an oddball claim nevertheless.

.

Here's the current Mauviel line usuing two: https://www.mauvielusa.com/products/FamilyGroup.html?categoryId=95

-

Yes, preheating with oil is the same advice for tinned as well. Far too much is made of tin melting. In normal use, it's a non-issue.

-

Well, you're just going to have to wait for BCC to offer a 28cm saute.

At the IHHS show in March, Mauviel's USA distributor told me they've changed to 2 rivets, in order to show the brand in between.

Tin vs. SS... We've had that debate ad nauseam. Searing can be done under 450F; if you want to dry sear above that, great, either don't worry about the tin or break out the CI. It's not an issue with saute.

-

Brooklyn Copper Cookware 3 Quart Sauté—Worth the Wait

Figure 1 -- It's here!

The BCC Story

A few years ago, what started as an arms-length business transaction with Brooklyn Copper Cookware blossomed into a friendship with its once and future owner, Mac Kohler. This was back when BCC’s production work was done with the help of Hammersmith. For those who don’t know, Hammersmith was heir to the old and well-worn machine tooling used to make the long-defunct Waldow lines of American copperware. From BCC’s founding, Mac has always had the passion and vision to make copper pans—top grade pans—in America again. BCC and Hammersmith succeeded in making very good wares, and developed a loyal following.

What Mac did not have in those days was a means to produce true restaurant- and hotel-grade copper pans, what we collectors and the French cuisiners call “extra fort”. While “fort” at 2-2.5mm in thickness makes for good pans indeed, 2.4mm was the thickest metal the creaky Waldow hand-me-down tooling could handle. Even chefs and cooks who could justify dropping $400 on a single pan sometimes balked at a 2-something-mm sauté when there were 3-something-mm ones to be had. And, some sniffed, what does an American know about making the very best copper pans?

What Mac also didn’t have was dependable production capacity to fill orders for BCC’s pans. This was partly due to the fact that Hammersmith’s work with pans was not their bread and butter—painstakingly making and fitting architectural metal in New York City rail stations was. It was also the case that skilled metalworkers were rare in Brooklyn. So orders lagged, customers started grumbling, and the copper snobs kept sniffing. When Hurricane Sandy, a major gas leak, and a lost lease conspired to halt production completely, BCC and Hammersmith went their separate ways, and it looked like the end.

Passion is a marvelous thing. Mac had it, never lost it. It took him and his new partner, Lane Halley, years, blood, sweat and tears, to resurrect BCC. Mac turned to the heartland to find the materials, tooling, capacity and worker skill sets he would need to make extra fort pans, cast his handles, assemble them, and line their wares with tin. BCC utilized a top casting designer for what are destined to become iconic iron handles. It’s a success story within a success story: Not only are BCC’s pans American-made, they’re produced by metal crafters in America’s rust belt who kept these irreplaceable skills alive like a lost language. And, as you’ll read, while the BCC v2.0 pans are at least the equals of the greatest European makers’, they stand apart as unmistakably American in form.

Fair disclosure: Mac gave me this pan to review.

A Pan by the Numbers

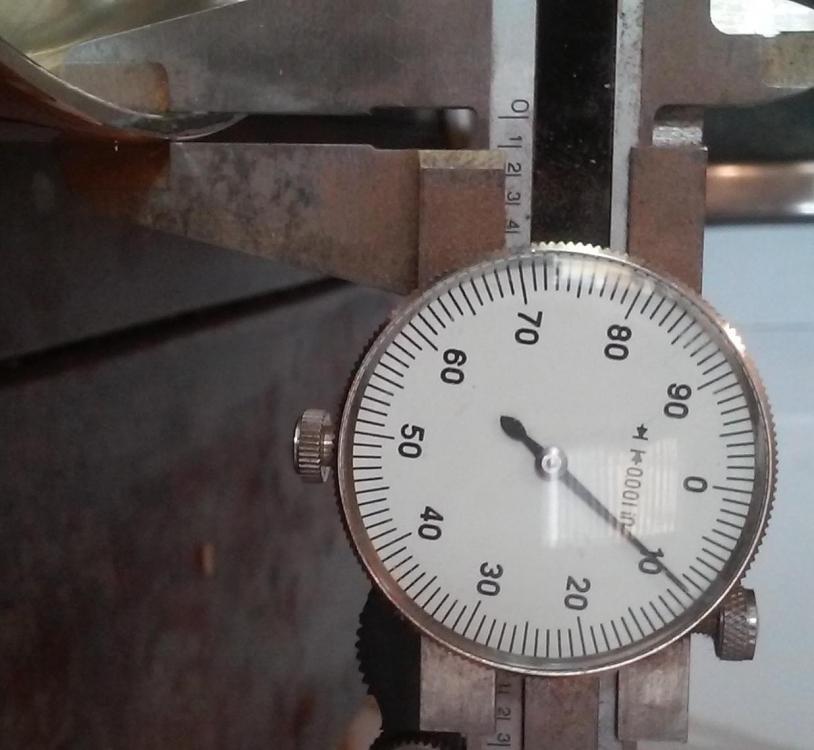

Figure 2

At present, the pans BCC offers (sauté, rondeau, casserole, and stockpot) are all 9.5” or 24cm in inside diameter. This number relates to the fact that all can be spun using the same 9.5” diameter lathe tooling. Sautés, unlike frypans, are sized not by diameter but volume; in this case the sauté is truthfully advertized as 3 quarts. However, putting 3 quarts in this pan entails raising a meniscus above the pan’s rim. One quart submerges a rivet, and two quarts would be all the liquid a jittery cook would ever put in it. The floor of the pan is 8.25” or almost 21cm in diameter.

This sauté weighs 6.8 pounds, or roughly 3 kilos. Needless to say, this feels heavy, especially at the end of a handle—few cooks will be able to jump this pan one-handed. Fortunately however, BCC has paired it with both a long (10”/25.5cm) tongue and a loop helper handle. Much more on those in a minute, but for a pan this heavy, it’s been made as jumpable/shakable as possible.

The pan stands 2 11/16” or 6.8cm tall at the walls. This yields a height-to-diameter ratio of 1:2.8, which is a classic proportion for sautés. Its total overall height, from underside to handle top, is only 5.75” or 14.7cm. This makes it easily stowable in short cupboards and shelving. The short handle rise also allows this sauté to hug within 4 inches of a wall when hung from a hook; compare this with over 6” protrusion for most classic sautés.

Figure 3 --Note the Protrusion Difference

When hung freely from an overhead rack, the pan only occupies 6” of horizontal space—a saving of 2 inches over my other sautés. However, the long tongue and helper handles together mean that the pan’s overall length is a surprising span of 22 inches.

BCC states that its pans are made from full 1/8” copper foil. It also advertises that its pans are 3mm thick. Since 1/8” is almost 3.2mm, I asked Mac why BCC doesn’t tout the higher 3.2mm number. The answer came back that, while the foil itself is 3.175mm, the turning process moves material on the mandrel, effectively stretching and thinning the walls as the pan is formed up to the rim. My measurements verified that the sauté’s floor is indeed 3.2mm, and that the walls measured between 0.108 and 0.110 inches thick (2.74-2.8mm).

Figure 4 -- Wall is 0.015" or 0.3mm thinner than floor

At first glance, I was doubtful the walls were even 2.7mm thick, but the weight told me otherwise. On closer inspection, however, I found that both the inner and outer edges of the rims had been “broken”, or rounded over ever so slightly. This was, I was to discover, just the first of several classy finishing touches BCC gives its pans. Bottom line: Where it matters, this pan is 3.2mm.

Figure 5 -- Still thick. Note gentle rounding of edges.

BCC Has it Handled

One thing that sets BCC apart is its unique, robust cast iron handle designs. Mac hired noted designer Barbara Stork to create something distinctive, yet completely functional. What BCC and its customers got were works of elevated art. These designs are so beautiful and detailed, in fact, that BCC chose to cast its mark in the handles rather than stamp it on the pan body (There is a designator mark “S3” stamped on).

The tongue and helper handles on the sauté are unique to this pan (The rondeau, casserole and stockpot each have two different loop handles, and the universal cover also has a different tongue). Classical French sauté handles typically rise almost vertically from the flange and, after a curved section, climb in a straight line at a relatively steep rake of up to 40 degrees; a classic French sauté can have its loop end perched nine inches above the hob. This traditional design is good for leverage and carrying, but the vertical start makes cleaning the pinched space between handle and pan difficult. And a high handle oftentimes means the sauté won’t easily fit in an oven; even if it will, it must usually sit alone on a bottom rack, hogging the whole space. Potatoes go cold while the veal medallions finish…

The BCC tongue handle solves both problems. Its shaft leaves the flange at a much lower angle, and there is a nice ¼” space left built in between the handle’s shaft and the pan wall, both of which eliminate that gunk-trapping crevice on other pans. Also, the BCC tongue itself is a compound curve, which allows it to sit lower overall.

Figure 6 -- Note handle's compound curves.

Depending on your oven, this may mean using your oven for more than one dish at a time, or being able to place your sauté on a middle rack. This alone is a big improvement.

Figure 7 -- Finally, the pommes can stay in the oven!

The BCC tongue gives up more surprises when you grasp it. For the first 2/3 of its length, it has a pronounced underside rib which makes the pan less “turny” when gripped over- and underhand.

Figure 8

And the large hanging eye actually curves up over its final 1.5”. It took me several uses to realize this, but with an overhand grip, the heel of your hand fits comfortably into the little dish formed in the oversized eye; this helps with leverage.

Figure 9 –Also a FigFigure 9 -- Also a pivot point

Figure 9 –Also a FigFigure 9 -- Also a pivot point

Finally, the symbolic “mark” is on a raised rectangular cartouche, which doubles as a very nice thumb stop/rest when choking up on the handle.

Figure 10 -- Alchemy for your kitchen. Note ample cleaning space between wall and handle.

Wiccans reading this may recognize BCC’s mark as a fragment of the alchemical symbol for… copper (I didn’t. I had to ask.).

Figure 11 – Your mark of quality and gnosis.

I’ve never seen anything quite like the helper Stork designed for the BCC sauté. I think it looks like a leaf. I was skeptical at first about it, but after use, I think it’s very ergonomic. It is technically a bent loop, with room to accept a very large finger, but it also functions as an “ear” that can be securely grasped with a side towel or mitt. This is brilliant.

Figure 12

The tongue handle is secured by 3 large rivets in an inverted classic offset pattern (contrast with Mauviel and Falk’s two).

Figure 13 -- Classic pans have the one center rivet above, two flankers below.

As you can see, even the handle flange got special attention. Rather than start with the traditional, boring blob-shaped flange, BCC and Stork imparted a little flair with a gentle point and swoops.

The helper is held fast by two more husky rivets.

Figure 14 – No bean-counting engineering here.

All 5 rivets are decidedly stout, with a shaft diameter of 0.315” or just under 8mm. While the rivet heads are smaller than those monsters found on the best vintage European pans (and the Duparquet homages), they are substantially larger than those tiny blips used by Falk, Mauviel, Bourgeat and other modern makers.

Figure 15

Finally, the handle castings are perfectly textured where they should be for grip, but smooth where they could bite or scratch.

Tinning, Fit & Finish

The lining arrived very bright, almost mirrored, a finish that I normally associate with electroplated tin.

Figure 16

But a glance in good light reveals the sworl marks that come with a hand-wiped lining (more on this in a second).

Figure 17 –Machines can’t do this. Ohioans can.

I have no means of measuring the tin thickness, but I’m told this falls between 0.35mm and 0.45mm. Note that this is roughly twice as thick as the stainless linings in bimetal pans. BCC’s linings should last decades with proper utensils and care.

The top surface of the rim was uniformly tinned, no mean feat considering the edges had been broken. I learned that this rounding of the edges is not merely a matter of comfort. It turns out that when sharp corners are tinned, the tin is prone to seize and come off when, e.g., a wooden spoon is rapped on the rim. I’ve personally experienced tinned rims blistering when nowhere else did; this may be why.

The exterior arrived polished brightly, but well short of a mirror finish. In fact, the pattern imparted by the cutting rouge was still visible in good light. Having said that, this is definitely not a brushed finish like Falk’s.

The fitment of rivets and handles is tight, square and flawless. I have never seen better.

Finally, a wonkish word on hardening. This subject would not normally fall under finish but it belongs here for this pan. That is, traditionally, copper pans were worked to shape in stages, originally by hammering the soft metal. Hammering (a/k/a planishing) hardens the copper. This is good in a finished pan, but can be bad if there’s forming yet to be done, because hardened copper can crack when it’s worked. Coppersmiths learned that their work could be resoftened by heating, annealing the metal so it could be further worked to a pan’s final shape without cracking. Pound a little, anneal, pound some more, repeat. After forming, the best pans got a final session of planishing, intended to work harden the copper. Harder pans meant longer-lived, flatter pans, and so the planishing marks became recognizable signs of high quality. Uniform, interlocking patterns became the beautiful, prismatic “painting” on the “canvas” of the copper.

BCC’s pans are obviously not planished, but they are work-hardened. Because they are spun on a lathe and formed in one fell swoop by a craftsman using his hands and ears, they get their hardening all at once, while they’re being made. BCC’s website explains this in deep detail; suffice it to say, stamped copper pans don’t get hardened this way, and the bimetal ones can’t be hardened by planishing—if it weren’t for the thin steel liner, they’d bend, warp and dent like crazy. The BCC craftsmen listen for the sounds the copper makes as they work it, and the art is in fully forming the pan just as the metal rings like a bell. The BCC pans needn’t be planished to be hardened. Ergo, planishing would be purely a cosmetic, expensive finish.

Astute readers of BCC’s website might wonder as I did: If BCC applies linings after preheating its pans to 1200F, why aren’t they annealed back to soft and don’t they lose this work-hardening? The answer turns out to be that only the surface of the metal is brought to that perceived temperature, and much cooler (500F) molten tin is quickly ladled in to moderate the heat. Yet there’s enough stored heat left to keep all the tin flowing and get a good, thick, even wiped coating. This is yet another example of the craft required to make these pans correctly.

Comparisons

BCC’s website describes their pans as: “… merely the best and most beautiful copper cookware in history.” Now, I know Mac to be a temperate man, not prone to puffery, but is this objectively true? Is such a claim of the reasonable-minds-can-differ flavor, or is it pride and hyperbole?

The only way I can judge is to compare this pan with the finest vintage copperware I own or have handled. I do not have another 24cm sauté, but my best extra fort sautés and rondeaux are three made by the famed house of Gaillard, one sauté a 22cm and the other a 28cm, and the rondeau a massive 36cm.

I can objectively state that my Gaillards are thicker, close to 4mm bottoms. I can also say the Gaillards are marginally thicker in the walls, “miking” at between 3.0 and 3.1mm average (compared with this pan’s nominal 2.8mm thickness). Measuring these planished pans’ walls is uncertain to some degree, because the hammer blows push the copper about, making it thinner where the center of the hammer fell and thicker around the edges. Gaillard was also famous for intentionally tapering its walls toward the top—its pans were sometimes well under 3mm at their rims and much more than 3mm in the bottoms. But if greater thickness alone in a sauté equates with best ever, BCC may be fudging a little. However, Gaillard has been out of business for a long time. Other than a handful of tiny boutique ateliers, I don’t think anyone is making copper sauté pans any thicker than BCC’s.

Interestingly, the 24cm BCC saute’s gentle shoulder radius means that the 8.25“/21cm floor is large enough for three of the enormous chicken breasts now dominating the consumer market. In comparison, my 22cm Gaillard, with more acute corners and a slightly smaller floor of 7.875”/19.7cm, would only fit two without crowding. In other words, the BCC pan cooks “bigger” than the 1cm floor size difference would indicate.

I can also say that, poor cook that I am, and sautéing not happening on the walls, I can tell no performance difference between these pans. So any debate about “best” in this lofty class of pan necessarily devolves into a near-theological debate. To keep things real, if BCC’s pan is the thickest one you can buy new, and it ranks 99.7% (compared to 80% for best-in-class clad), and the only arguably “better” pan ranks 99.8%--and is unavailable—why isn’t BCC’s the best?

I have no problem whatsoever judging the BCC sauté as attaining the finest level of fit, finish and ergonomics I’ve ever seen. Nothing else I’ve handled comes close.

On the aesthetic side, the Stork handles are beautiful in ways that a classical pan’s handles have never been. In fairness, no one before lavished such design acumen and attention on functional handles for copper cookware. Simply as a matter of industrial design, these handles are masterpieces; if Alessi copied these handles in stainless steel for some Danish designer’s clad pans, they’d instantly be on display in MOMA.

I confess I prefer the look of planished pans, and I still consider planishing a mark of quality. But I accede that it’s not a necessary condition for attaining work-hardening. There are also some touches on some vintage pans, e.g., stepped chamfering on the bottom/wall radius (barely visible in Figure 3), that I find particularly beautiful.

Finally, the form of BCC’s pans is distinctly American even in ways that transcend those glorious, muscular Stork handles. I find intrinsic beauty in this, even if I can’t fully articulate all the style elements.

The Beauty Marks

This is the hardest part of this review to write. Far be it for me, a spectator and dilettante, to deign to tell BCC what it could do better. There are probably 100 reasons I’m wrong to quibble over minutia, and it’s all just my opinion, but here I go, telling Rembrandt how to paint…

I find the overall length of 22 inches too long to fit on a crowded cooktop. I wish that—for a 24cm sauté—the tongue was shorter, and I may have omitted the helper on this size pan. For comparison, my 22cm Gaillard’s handle adds <7 inches to the pan’s overall length; if it were fitted to the BCC sauté, the OAL would be more like 16 inches overall.

I wish BCC had found a way to employ inner rivet heads that sit flush with the pan wall. I put this in the “nice touch” category rather than a problem.

The leverage could be better. Perhaps this is because I’m accustomed to high-rake, traditional handles, but the 6.8-pound, 24cm BCC pan feels more than 1 pound heavier than the 5.8-pound Gaillard 22cm.

For my large hands, I wish the waist of the tongue handle had been kept a bit fatter—it still feels slightly “turny” like some Mauviel pieces.

Figure 18 -- Handle waist viewed from beneath

As long as I’m fantasizing, offering a silver-lined option would be nice. Make it thick Sheffield plate while you’re at it, Rembrandt.

Final Words

Upper 99th percentile in performance. Flawless fit and finish. Iconic styling. Versatile size. Designed and made in America by really good people. Immortal. Stunningly beautiful. The best pan of any kind available at retail. A value at $400.

This pan will either make you cook better, or care about cooking more—in which case, you’re also likely to cook better. If consumers have any sense at all, BCC v2.0 will be a smashing success.

To Learn More:

Brooklyn Copper Cookware, Ltd.

687 Jay Street

Brooklyn, NY 11201

(347) 866-2600

www.brooklyncoppercookware.com

-

1

1

-

-

9 hours ago, andiesenji said:

They apparently had boneless picnics for $1.78 a pound but someone bought all they had and they won't get another shipment till next Tuesday and can't guarantee they will be at the same price.

I phoned the Walmart over on the west side of Lancaster - same thing, they only have 7 of the bone-in picnics left, all the boneless are gone.

Probably the guy who has the mobile barbecue rig. I saw it in the parking lot when I was there yesterday morning early. He does "events" like the air show and the motocross and things like that.

Cooked it turned out beautifully, very moist, tender, not much grease, perfect pulled pork.

I am going to make pork and sweet potato hash for dinner.

It's one of the dishes I have found that is greatly improved with the addition of preserved lemon.

If you have a Cash & Carry in your area, this is a normal price for 15-20 pound Boston Butt, already boned.

-

10 hours ago, xetaprime said:

Thanx! Good to be here! I know, Classic American cookware that was quality made- where'd it go? Not even sure why I've been infected with the Magnalite Bug but I find myself collecting them now. Haven't used them yet but it will be fun cooking in a pan maybe older than I am, I think

Now go out and find yourself some Club and Gaillard aluminum. The omelet pan made by Club is a classic, almost 7mm thick. They put Rudolf Stanish's name on them. There's a "houswife" version that has a phenolic handle and a painted exterior, but the real find is the bare resto version with the steel handle. I picked up the latter for $10 and it's the best omelet pan I've ever used.

-

10 hours ago, Smithy said:

One of my sister's friends makes decorative wine stoppers, and gave one as a gift to my sister. My sister put the stopper into a partly-empty bottle of blackberry-infused balsamic vinegar, and left it in place for some weeks. There was no contact between the stopper and the vinegar, based on the level of the vinegar in the bottle and the fact that the stopper wasn't wet when my sister removed the stopper next. When she removed the stopper, she saw a layer of crystals growing on the stopper. There didn't appear to be any corrosion. I don't have photos of its appearance then, but she packed it along on a road trip in a bag, and this is its appearance now:

Questions:

- What is that corroded layer made of?

- Assuming that the atmosphere in the bottle caused that corrosion, is the vinegar still safe?

Toss it. Sorry. Salts from copper or brass are toxic. If it's zinc, it will make you sick and induce copper deficiency. Nothing good can come of this, except maybe a bag of real corks for next time.

-

3

3

-

Not to discourage you, but there are many, many better primers on induction hobs, how they work, and what compatible pans are on the market. See, https://www.centurylife.org/how-to-choose-a-cooktop/how-to-choose-a-portable-induction-cooker-countertop-burner/

And for the cookware to use on it, see, https://www.centurylife.org/how-to-choose-cookware/

The latter has a dandy little filter tool, so you can narrow the choices. This guy's work is top-notch.

The cheap PICs (portable induction cooktops) go for $50-$100, so factor that into your $130 price difference.

I don't know what I'd do with a 6Q stockpot. 8Q is pretty much the minimum size I use.

-

Hi, robie:

Here are two blades I made and a vintage Zwilling glestain slicer. The "sandwich knife" is SS and chisel-ground. The "Euro Chef" is flat-ground. Both are quite thin for vegetable work on a board, at least as thin as the slicer.

If you want a rocker to the edge and work on a board, I would just go looking for the thinnest chef knife you can find with a decent drop. The Japanese knife nerds sometimes call these "lasers". If you don't mind a completely straight edge--and don't need a tip, those cheese/kamagata knife geometries work well.

Slicers and pettys can be frustrating for cutting anything that is not perched high on something, be it a board or in a pan or rack. If you're cutting against something, you end up dragging the tip through the last of it, which can dull it there quickly, which means you will tend to tear, not cut. This wear happens nauturally over time, which I think is the explanation for the very slight rounding at the very tip of nakiris--now they just put that line on at the factory.

-

3 hours ago, btbyrd said:

t would be nice to have a grease trap around the edges for things like hamburgers and bacon.

I have one of these that works fine if you have room to dangle the edge over the front of your top and hang a little grease-catch can...

-

4 hours ago, btbyrd said:

It will probably get more use as a plancha than a pizza steel.

Beats going to the gym for a deadlift routine.

What hobs are you putting it over? Are you getting acceptably even heat? I ask because the first prototypes of the hyperconductive cookware I'm working on are rimmed/troughed plancha/teppanyaki. Hopefully, I can post some FLIR thermography soon. I've cooked on it in the lab, and you can put a small gas hotplate at one extreme end, and cook burgers at the other end, 18 inches away.

-

Take a look at RDM's products. http://www.rdm-ind.com/x-tops.htm

-

17 minutes ago, pastrygirl said:

I believe richter farms here in the NW starts the season with hothouse then moves to field grown rhubarb.

With the absence of winter in the PNW (daffodils blooming in February!), you should have rhubarb soon enough...

-

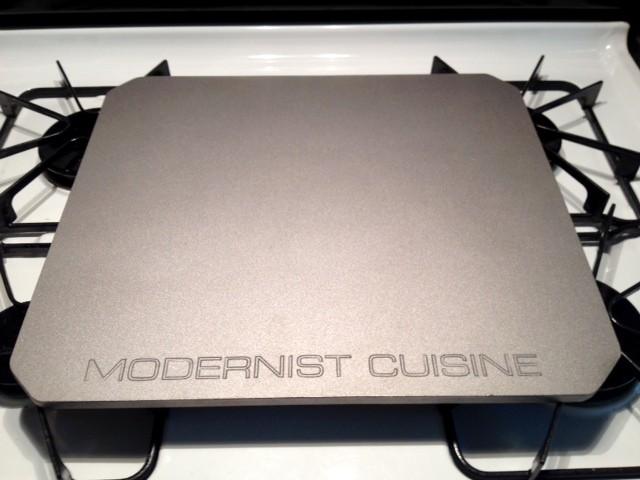

1 hour ago, btbyrd said:

Pizza Steel: A Seasoning Story

A couple years ago, I got myself the MC edition steel for my birthday. It was beautiful and seriously heavy. I was so excited!

The first time I used it, however, it developed some serious rust spots. I used it on my grill for two pizzas and a steak. After use, it was still far too hot to move, so I let it cool down overnight in my covered grill. It wasn't a rainy night and I'm not exactly sure what happened, but the next morning my steel was a freaking rust bomb.

The horror. At this point, I moved the steel to a cool dry place where it sat for a year and a half. Until this weekend.

Cleaning the rust bomb was a rather involved process. I did a 24 hour vinegar/salt soak followed by vigorous scrubbing with steel wool and BKF. The vinegar worked wonders, but the wool and the BKF not so much. So I grabbed a pack of the Grill Stone blocks that the Baking Steel people recommend and went to town. Those things work extremely well, but I used a box of 3 for this (admittedly nasty) job. They're sort of like Magic Erasers for use on metal. After the scrubbing, the steel looked a lot better. It was actually much cleaner than it looks in the picture.

I spent much of this weekend seasoning it to build up a solid rust-proof coating. This is after 3 coats. I think I"m finally done.

So nice... and I'm finally able to use it again! If were to buy a steel again (for the first time) I'd season it once or twice immediately (even though it comes pre-seasoned) just to give myself some extra rust insurance. I also like the uniform darkening that the process creates.

Anyway, the moral of the story is that you shouldn't leave your steel outside overnight -- even on a dry evening. And if you do, grab some vinegar and some scrubby rocks and kiss your weekend goodbye.

Please post a photo after your first 20 pies on this seasoned surface. If it's like my steel, you're just ahead to scrape it with a bench scraper or stiff putty knife, wire brush it, then wipe it down with an oily rag. It's gonna look rasty in short order, no matter what.

Best new product

in Kitchen Consumer

Posted

Yes, $15 for a minty Super 3600 at a grange sale. The seller was tired of it cluttering her counter, so I owed it to her to take it off her hands. I probably could have dickered her to $10, but that would've been so wrong...