choc.frogs

participating member-

Posts

11 -

Joined

-

Last visited

Recent Profile Visitors

818 profile views

-

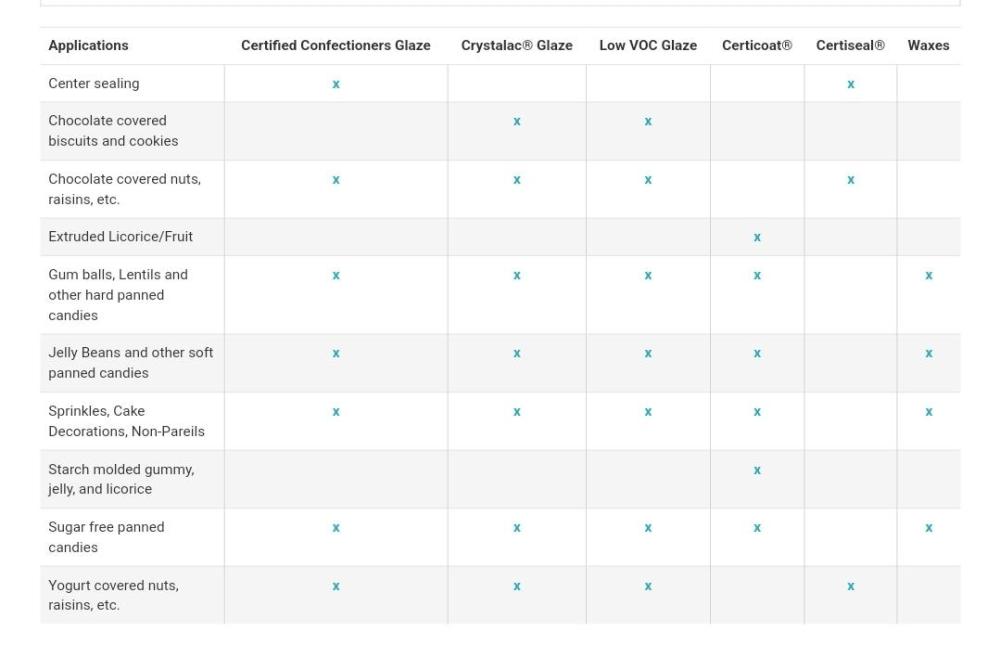

Thanks Kerry! The waxes seem geared to hard shells.. per the chart below it seems like the offerings are either Certiseal or Vegetable based protein glaze (mentioned in the chocolate coatings and then glaze section). Unfortunately I'm not in the US, rather in the UK although I'd happily pay the shipping if I was able to get a small batch. Really useful though! I'll try and speak to their contact support, perhaps they can guide me elsewhere or to trade shows more local to me.

-

After much research on finding alternatives to Shellac as a glazing agent in chocolate panning, the alternative I've found is corn (maize) protein called Zein. Gum arabic has been floated in the past but its more of a polishing agent with little glazing properties i.e. protection against moisture in a high humidity environment, prolonged shelf life, aesthetical protection. Has anyone had any experience in working with this or alternative vegan Glazing agents? Any pointers on where one can find this or a suitable alternative in limited quantities?

-

my aha moment! I do sometimes leave my decorated moulds in the fridge between decorating and chocolate tempering lags and I have noticed that the CB in the mould pulls away. I'd just never though that chocolate could seep in between! I will certainly test that out if(when!) it happens again. I was using demispheres when this happened. Hasn't happened to me using quenelles or a bunch of other shapes but I haven't used them in years. The only thing that's changed are my patience levels and thus holding technique but now it's occurred to me it's the added fridge step due to being in a warmer climate.

-

..also what I'm scared of. I'd overheat the edges and the cocoa butter design will melt/seep through as well. I've had this at times when I've loaded the mould with chocolate incorrectly (rather than the 90 angle held the mould at 45) and as it pours over in to other cavities the cocoa butter melts off the edges slightly. A mm or 2 but enough to be noticeable. Tbh I'm also a bit of a fire hazard in the kitchen, all in all it's probably best to err on the side of caution 🤭 A hair dryer (if needed) it is 👍

-

I've got away without heating so far but I've sometimes had leakage issues (might be to do with overfilling or an excessively runny mixture). Though I've never had breakage as such. TBH heating to help create a bond between the shell and base had never occurred to me until I visited this forum. having seen so may videos of it I wondered if I'd been missing a step.

-

Hi guys, When sealing bon bons what do you use? Do you leave the bon bons out to come back to room temperature or heat the edges? If using heat, what would you use (& recommend)? Could I get away with a small travel size hair dryer? Thanks

-

Thanks! @Jon S I haven't experimented with ganche mixtures enough. Mostly been the aesthetic side of bon bons (pics aren't the best but you get an understanding) Looking forward to our discussions

-

Spraying Chocolate: Equipment, Materials, and Techniques

choc.frogs replied to a topic in Pastry & Baking

whopping* to clarify: +0.7mm for airbrushing coloured CB; and ~2.0mm for spraying CB and Choc mixture for the velvet effect -

Spraying Chocolate: Equipment, Materials, and Techniques

choc.frogs replied to a topic in Pastry & Baking

I've read through the whooping 34 pages - can I summarise then that the recommended nozzle sizes are; +0.7mm for airbrushing coloured CB; and ~2.0mm for CB and Choc mixture for the velvet effect? For the latter, does it have to be 2.0mm - do you think I could potentially go lower to a 1.8/1.4? Any experience or recommendations? If not, I'll stick to the 2.0mm guidance. Also, I'd second what Jim D said earlier re trigger style airbrushes vs one's with a toggle at the top - pricier but much more comfortable/easy to use. I've struggled with a painful, often swollen, index finger with the the toggle type. Perhaps I've never fully understood the correct hand posture considering it is used in other industries with prolonged use but it's a never again for me. -

Does Callebaut 811 work for molding filled chocolate shells?

choc.frogs replied to a topic in Pastry & Baking

I felt the same way in the beginning, especially when you notice the change in the fluidity as the chocolate drops down to 32 C. I've never really had a problem with thick shells but I couldn' get the idea of a higher fluidity choc out of my head and decided to experiment. Thinking I new better than a chocolate production brand was quite the mistake - Big Homer D'Oh moment for me. I thinned the 811 & 845 (separately) with cocoa butter and was delighted with the result when casting my moulds and emptying them. Once they were "set" or should have been set, I realised I couldn't get them out of the mould. After much searching I discovered it was because the chocolate shells were far too thin & therefore weren't able to contract enough. Not an experiment I'll be repeating but thankfully it was fixable. Added a bunch of more chocolate to the mixture which fixed the fluidity (I was working with small amounts to begin with which made the fix an easy one!). -

Hi All! Recently joined the site (long time lurker) as a novice/hobby chocolatier. I got in to the world of chocolate after attending an annual chocolate fair in London way back in 2014. It was love at first taste for Aztec chilli truffles and Lauden's decorative chocolates served on BA flights (which I now know is done using transfer sheets). I went from making truffles to buying a bunch of different moulds to experimenting with cocoa butter and airbrush/sprays. A lot of the regulars comment that there's no such thing as a one time attempt - this couldn't be truer for me! I've learnt so much from the regular contributors and yet there's still a very long way to go. I look forward to being able to contribute some and meanwhile interact with the others on here! Choc.frogs