-

Posts

2,411 -

Joined

-

Last visited

Content Type

Profiles

Forums

Store

Help Articles

Everything posted by Jim D.

-

I'm still thinking over the baklava possibilities, and honey definitely has to be in the mix. Any honey plus white chocolate ganache I have found sounds as if it would be teeth-torturingly sweet. I don't see that a milk or dark chocolate ganache would be part of the baklava taste.

-

Another thought just popped into my head: There is such a thing (I had to consult Google) as dried honey. I have no idea what it tastes like, though I have some molasses powder that tastes fine, but it might even be possible to put all the flavors (not the rosewater) into the gianduja. But I think I would go with the two layers for the sake of contrast.

-

I agree. I wouldn't expect feuilletine to stay crisp when mixed with a ganache. What I would try is to make pistachio gianduja instead of a ganache. It has more flavor than a ganache can deliver. What I do is to toast some pistachios (very slightly--I know some people disagree with the toasting, but a side-by-side test left me thinking toasted is better). Then melt pistachio paste and white chocolate to make gianduja, plus some feulletine (if you want more crunch since pistachios aren't really very crunchy). Pipe a tiny amount of the gianduja into each cavity, sprinkle in the pistachios, then pipe more gianduja on top. My thinking on this somewhat elaborate procedure is that is if you try to pipe pistachios mixed in with the gianduja, they will stick in the piping bag, and if you put the nuts in first, air bubbles will form (experience speaking), so they are enclosed in the gianduja. Let that set. In keeping with Peter Greweling's thoughts on migration within bonbons, I would paint the gianduja layer with a thin layer of melted cocoa butter (obviously this step is optional). Then you could make a ganache layer (getting the honey and cardamom flavor into that, maybe even some rosewater--some baklava has it) and pipe that on top of the gianduja. In thinking about this whole idea, I am getting inspired to give it a try myself.

-

I know what you mean by looking "forced." I have that same trouble when using a sponge, whereas others seem to have it all blend together with no obvious separation between the colors. If you want to be really depressed, take a look at the Gallery section of Monde du Chocolat. Coming close to replicating the Easter eggs are a goal of my life. Someone suggested that somehow blending in some white cocoa butter makes it all come together.

-

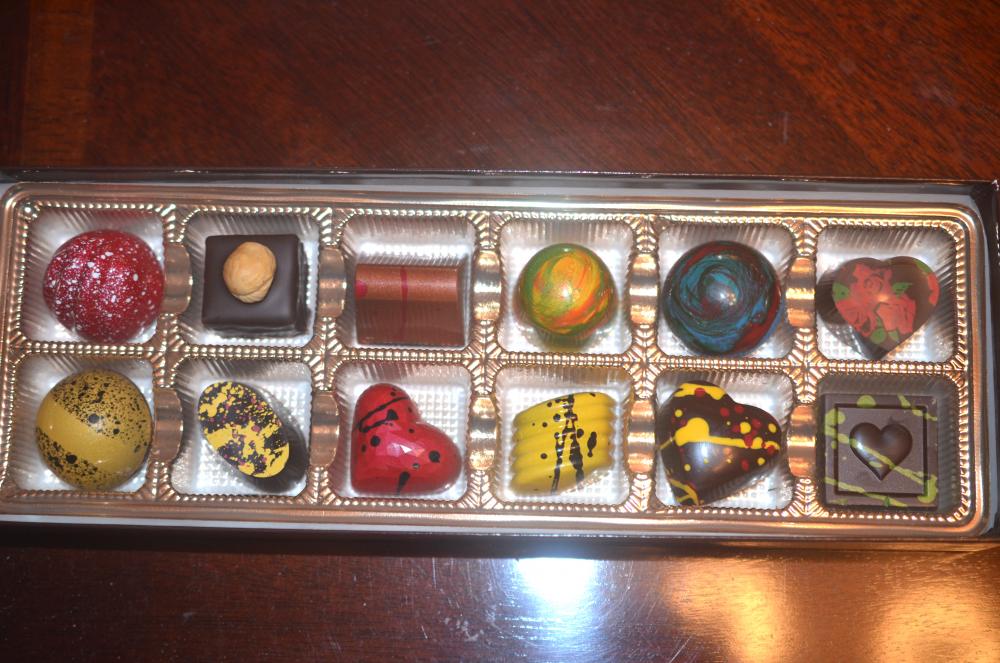

My Valentine's Day assortment for 2021: Top row: (1) "pecan pie" (dark caramel, pecan praline gianduja, pecan shortbread), (2) coffee ganache with Kahlúa & hazelnut praline gianduja, (3) "crème brûlée" (vanilla buttercream with crunchy caramel), (4) milk chocolate & caramelized sesame crunch, (5) dark chocolate ganache with absinthe, (6) "raspberry rose" (dark chocolate ganache with raspberries and a dash of rosewater). Bottom row: (1) Speculoos cookie butter & milk chocolate, (2) passion fruit ganache, (3) dark caramel with Maldon sea salt, (4) banana & passion fruit caramel, (5) almond praline gianduja with caramelized almonds & dried cherries, (6) squares of Arriba 72% with peppermint oil. All pieces were enrobed in one of two Felchlin chocolates: Maracaibo Clasificado 65% or Arriba 72%.

-

Perhaps I should not use an electric mixer to cream the butter and sugar to start--although doing it by hand does not sound like an easy task (yes, I do know electric mixers have not always existed!). But why would the "crater" effect not happen with larger pieces made from the same dough?

-

@jmacnaughtan, others on eG have mentioned making a pipeable layer with crushed gingersnaps or graham crackers, and I have experimented with that concept. You are certainly correct that it takes some "playing around" to get the right mix of the crushed item and whatever holds it together. Cocoa butter and the crushed cookie tasted horrible; chocolate tended to cause the layer to lose its crunch. Most recently I tried @Rajala's idea for a gingersnap bonbon. It calls for partially crushing gingersnaps and adding chocolate, ghee, and coconut oil, but my attempt lost the crunch (I finally made gingersnaps instead, and the resulting filling was delicious). After my experiments, I concluded that a "praliné layer" (as it is called by some) does not come close enough for me to the crunch of a cookie. It is an idea certainly worth more experimentation because it is so much easier to pipe in a layer rather than add a cookie plus a "moisture barrier."

-

No, but I will the next time I make them. Thanks.

-

350F, for about 15 minutes or until they brown slightly.

-

These go into a dome, so the curved bottom wouldn't hold the cookie. The appearance of the cookie doesn't really matter since it will be surrounded with gianduja (or a meltaway or chocolate); the issue is that it almost dissolves if it is too thin (and if it's too thick, it take up too much room in the cavity). Let me see if a photo makes it clearer: The crater at the left is the problem. The cookie gets too thin at that point. They work, but they could be better, and (I am discovering) if they are thicker, this issue doesn't happen as much. But, as mentioned above, at that point they take up too much room. Today I was making a "pecan pie" bonbon: On the bottom, a thin layer of salted caramel, then some chopped toasted pecans, then pecan praline gianduja, then the cookie (it's pecan shortbread) pressed into the gianduja. You can see that thick cookies present a problem.

-

I don't have that particular issue. I make shortbread cookies as inclusions in chocolates. They are about 3/4" in diameter. It's difficult to explain, but the bottoms often come out with indentations; the tops are fine, the bottoms are almost lacy in appearance. It doesn't happen with every one of them, and when I have leftovers (and the cook feels like a little shortbread reward), I cut the dough into larger pieces. With those, the bottoms are perfect. It has something to do with the size of the circle, but that makes no sense to me. I have posted this issue before and have tried all the ideas presented, but nothing has worked. They are fine in the filling and remain crunchy (as desired), but this is a persistent annoyance.

-

@kriirk, earlier in this thread, in your discussion of the NYT shortbread recipe, you stated that one should not make rounds from it: "Please also note that low flour content means non-suitable for making 'rounds.'" Can you explain why this is true? I ask because I often make round cookies from shortbread and have had some difficulty with them and am always looking for a solution.

-

I found this on Ecole Chocolat: And this:

-

Non-Airbrush Alternatives for Spraying Colored Cocoa Butter

Jim D. replied to a topic in Pastry & Baking

I am not so positive as pastrygirl about the opacity of the colored cocoa butters available. If they contain a great deal of white (identified--if you have an ingredient list--as titanium dioxide), they will be mostly opaque. This includes yellow, most blues, greens, and the metallic colors. Since I hate spraying that extra layer of white (which creates a huge amount of cocoa butter sprayed into the air), I am paying closer attention to which colors absolutely need the white. For example, I made a filling with orange flavoring and wanted the shell to be orange; I did not spray with white. I compared two molds, one before filling with dark chocolate, one after. The "before" one was definitely brighter. I also find red problematic; for me it gets muddy and requires white, or at least a light color, behind it. If I am making a red heart for Valentine's, which I will be doing all too soon, I want that red to pop. I don't know what access you have to U.S.-made colored cocoa butters, but a company called ChocoTransferSheets has a line of opaque colors, which contain a larger amount of white, a fact that, of course, makes them lighter in color. -

Non-Airbrush Alternatives for Spraying Colored Cocoa Butter

Jim D. replied to a topic in Pastry & Baking

Filling the cavities with colored cocoa butter would take an enormous amount of c.b., and the cost would be prohibitive; the layer of c.b. would probably be too thick, depending on its viscosity when you pour it in. The only alternative method I have ever found (to using an airbrush) is to use a fairly large paintbrush and brush in the color. Depending on one's ability, this usually leaves streaks as the c.b. tends to run and leave empty gaps in the colored shell. -

I have been buying from slofoodsgroup.com recently and have been satisfied with the quality. The Tahitian ones are especially fat and juicy. At the moment they have 25 Madagascar beans for $60 ($89 at beanilla.com).

-

Help with dark chocolate fudge and fruit caramel recipes

Jim D. replied to a topic in Pastry & Baking

I sent the link to the confectionery course to my friend. I did also find that adding baking soda is a recognized way of encouraging the fudge to set. -

Help with dark chocolate fudge and fruit caramel recipes

Jim D. replied to a topic in Pastry & Baking

A question on fudge: A friend (who does not belong to eGullet) asked me the following question. I am posting it here for suggestions, as fudge is well beyond my knowledge and experience: One of the treats I made for Christmas was a white chocolate raspberry fudge. It was very easy to make, tasted good, but had a terrible, sticky, gooey consistency. I read that adding baking soda would thicken it and give it a more fudge-like consistency. Have you ever had a similar experience? What do you think about the baking soda suggestion? Thanks for any suggestions. -

Never having tried bacon in a chocolate, I must ask what texture the bacon has. Flabby (like undercooked bacon)? I would think crispy bits might make for an unpleasant experience--bacon can get very crispy. If I recall correctly, in previous chocolate-with-bacon discussions on eG, it was concluded that using the bacon fat is the best way to achieve the desired result.

-

As has already been suggested in this thread, you must have oil-based colorants when working with chocolate. Water and cocoa butter don't mix (unless, of course, you are deliberately making an emulsion with them). I don't know what country you are in, but look for "oil-based" before you buy, regardless of whether it is pre-mixed colors or powder that you will mix with plain cocoa butter yourself. You also wrote about backing colors with white. Unfortunately, that is required with some colors, and you really know which ones only by experimenting. It often depends on how much titanium dioxide has been mixed in (since it blocks all colors). Most red cocoa butter, for instance, turns dark red/brownish when dark chocolate is behind it. But yellows, orange, light blue are usually OK without a white layer. I have found, however, that even colors that block most other colors (orange, for instance) show up brighter when there is a layer of white. You can experiment by melting the colored cocoa butter, spreading a little of it on a transparent surface (a piece of clear plastic, for example), letting it set, then spreading some melted chocolate on top of part of the colored area. When you turn the plastic upside down, you will see how the cocoa butter will show up with and without chocolate behind it.

-

Help with dark chocolate fudge and fruit caramel recipes

Jim D. replied to a topic in Pastry & Baking

I suppose buying your own cow would be too much trouble? -

Help with dark chocolate fudge and fruit caramel recipes

Jim D. replied to a topic in Pastry & Baking

Yes, similar, but it has more white chocolate (and no plain cocoa butter). I also add some dark rum. -

Help with dark chocolate fudge and fruit caramel recipes

Jim D. replied to a topic in Pastry & Baking

Sorry, didn't see this earlier. Wybauw has a banana and passion fruit caramel that (in my most recent measurement) ends up at .50 Aw. He uses cream plus banana and passion fruit in the caramel. The problem with it is that it is impossible to cook it to a usual caramel temp because it splatters so much and the banana tends to burn. So he calls for adding some white chocolate at the end, which eventually thickens the mixture. The butter tends to separate, but I mix the whole thing in a food processor, and it comes out beautifully and is delicious. -

EZtemper - The Help You Need to Achieve Perfectly Tempered Chocolate FAST!

Jim D. replied to a topic in Pastry & Baking

With your expertise in all things baking, you will master this--but perhaps best at a slower time of year! As you already know, you will find all the help you need on eG on tempering chocolate. Chocolate always has its surprises, but once you "get" tempering, it will not seem so mysterious. -

You could get colored tissue paper, which might look a bit better. As you said you include a pad, which I do as well, I assume people will realize the extra paper is for protective reasons only and probably throw it away.