-

Posts

821 -

Joined

-

Last visited

Content Type

Profiles

Forums

Store

Help Articles

Everything posted by keychris

-

ditto. I only really use guitar sheet for sealing moulds if I'm in the mood.

-

The problem I have with that technique is that it's kind of fragile, every time I've done it it tends to brush off very easily

-

your chocolate is squeezing the filling as it contracts. did you leave the shells to contract before adding the filling? Caramels are a pain in the butt 😛

-

I think you'll get too much insulation from wood, and I'd be surprised if it would release. Also there's hygiene issues with porous materials like wood.

-

to my eyes, you're capping in milk chocolate, and you can see the small amount of milk around the edge as you would expect from contraction. The white I have two theories for: the first is that when you're handling the moulds before you spray the white you're wiping off some of the red somehow, the second is that you're putting on so much red cocoa butter that it's contracted before you're applying the white and the white is then moving into the space between the red and the mould when you spray it. Can you show us pictures of every stage of the cocoa butter so we can see how much you're putting in?

-

Yeah, my response when I saw that was "are you bleeping kidding me" I like seeing these techniques, but the ones that are just so impractical as to be unusable I just shake my head at.

-

off topic, I had a panned smoked almond which was coated in milk chocolate and crispy bacon pieces, it was wonderful.

-

I do basically what @Chris Hennes says above, except my ratio is 1:5 starter to flour. Recently I've changed to a 50% hydration starter and it's going very well.

-

I've always sprayed at 86-88F (30-31C) with no problems. This is the method they teach at Savour in Melbourne. The cocoa butter in @eglies original post - if it's thick enough to chip, it's too thick as @pastrygirl said.

-

I believe the nibs are added to a clean mold, but because it's not a solid, even layer, some of the chocolate comes through and spreads out as you see there. I've had exactly this happen when creating easter eggs with inclusions on the shell.

-

it really depends on the bloom strength of your powder. I'd go by weight though, it's easy enough to find the weight of different strength gelatin sheets online.

-

They look great!

-

whilst an ez temper is helpful, it's definitely classified into the "expensive toy" category for me (sorry @Kerry Beal). But that's mostly because Australia is a long way to ship one and the exchange rate is horrible. I think if you want to experiment, you'll need a few polycarbonate moulds. You can temper in the microwave or by seeding, I did that for a year before I invested in a large piece of stone to table my chocolate on. I didn't have melting tanks for a year, I just did everything in bowls with a heat gun and as fast as I could. It's possible All the toys just make it easier. If you're looking to actually create things to sell, then you'll want some of the things that make it easier, because time is money. If you wanted, you could also enrol in an online class, there's a few around with a relatively low month to month cost which will provide you with heaps of info on the basics.

-

Chocolate making: Things I learned in my early months

keychris replied to a topic in Pastry & Baking

It is a lot! It's actually really useful information, as some of the pieces I do for Easter always ended up with super thin walls, I guess I was underestimating the amount of chocolate I needed by a looooong way -

Chocolate making: Things I learned in my early months

keychris replied to a topic in Pastry & Baking

heh, my technique. Except I don't have the snow 😂 -

Chocolate making: Things I learned in my early months

keychris replied to a topic in Pastry & Baking

How are you going to spin it? -

I feel that unless you have active cooling for your moulds (cooling tunnel, refrigerator), you probably don't want to add heat to the system, as the more heat you have there even at the same temperature as the chocolate is more heat you have to remove for the chocolate to set, and you'll be more likely to get bloom due to heat from crystallization pushing it out of temper.

-

it seems to be saying that you can have 0.5% of alcohol in your product that is only from "flavoring extracts" so I guess... like vanilla essence? Are the alcohols we use classified as flavoring extracts? Probably not. But this page itself isn't talking about labelling, it's saying that what you're producing is classified as an adulterated food.

-

How much kahlua is in the 2.5g? and what is the weight of the finished truffle?

-

Need more numbers. Total ganache weight, amount of wine in that ganache. Here come lots of assumptions. Let's assume 60/40 chocolate/wine ratio. Also assume each chocolate weighs 12g, but 2g is the shells. Leaves 10g of filling, which is 4g of wine. Let's say 12% alcohol content in the wine, leaves you at 0.48g of alcohol, which is 4% of the total product weight. Very rough figures, but I think you're going to be significantly higher than 0.5%. Is it as simple as just relabelling correctly or is getting the alcohol license a pain in the butt?

-

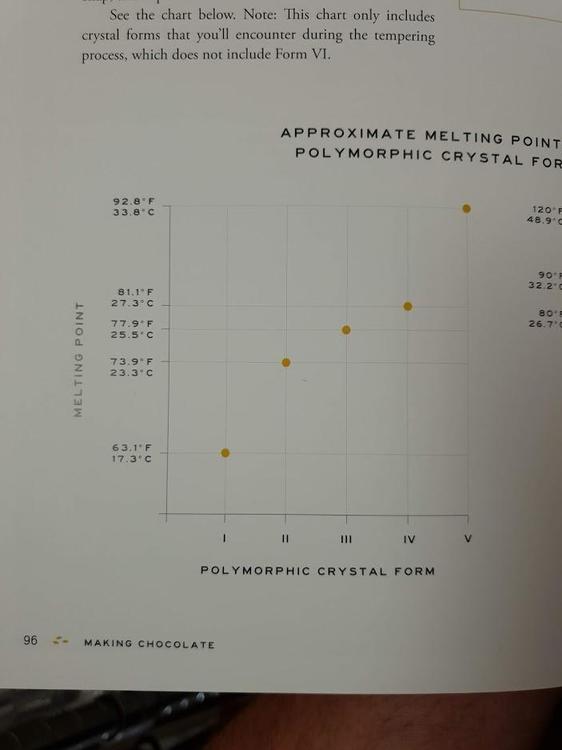

I remembered this topic when I found this graph in a book I was reading recently. I thought it showed nicely why you don't have to cool the chocolate lower than the working temperature, the other crystals don't start forming until under 28C. So if your temperature is higher than that, you're only working with Type V crystals and the amount of them. Of course, other fats are going to interfere in milk and white chocolates.

-

A scraper AND elbow grease AND warm soapy water.

-

I'd recommend contacting savour directly via the email on their website and asking if they know of anyone else that has any issues in argentina - they may be able to help you subscribe successfully. Disclaimer: I've been part of their online classes since day 1

-

did the pectin fully dissolve? the only time I've had an issue with pdf is when I didn't disperse the pectin in the sugar properly before adding it to the puree and it (the pectin) went clumpy and stuck to the sides of the pan

-

It also depends how you're applying the heat - if you're using a heat gun, you're generating a very high localised heat which melts the crystals in that area, but not the rest of them, then you stir and melt more, etc.