-

Posts

5,178 -

Joined

-

Last visited

Content Type

Profiles

Forums

Store

Help Articles

Everything posted by paulraphael

-

I'm interested in all of it, but especially preparations that are ready to use, whether you buy them or make them yourself in bulk. I'd never heard of Maggi. And I left Marmite off the list. An idea I'd like to experiment with: make tomato paste out of sun-dried tomatoes and keep in a small jar. Anyone heard of this? Maybe it can be preserved by using some vinegar?

-

I just like that this sci-fi looking piece of lab kit has a button marked AUTOeasy. It's like seeing that label on a time machine or a doomsday device.

-

I had a conversation with a friend who cooks mostly Japanese-inspired food. He thinks there's a conspiracy against umami in Western cooking. "What are your choices, besides a bag of Doritos?" The conspiracy theory didn't sit well—I could name a lot of things, from sun-dried tomatoes to parmigian cheese. But he had a point. Look to the east and there are countless preparations in a bottle or jar, always at the ready to fill holes in a dish's savoriness. Fish sauce (in its infinite varieties). Dashi. Soy sauce. Anchovy paste. Seaweed. Bonito Flakes. When I thought about non-Asian equivalents, the closest was worcestershire sauce, which tastes so much like worcestershire sauce its use seems limited. Other things seemed hard to use for other reasons: parmigian, tomato paste, pan drippings, bacon. What are your go-to concoctions? Anything unusual that you have to make?

-

Just push the AUTOeasy button.

-

I'm not trying to sell you on one; I haven't sold my self on one either (for many of the reasons you mention). But I don't see how they're suitable only for research. They're in use in quite a few professional kitchens, bubbling out concoctions for paying guests. Batch sizes are way beyond 300mg. Check out the rotavap section on the Cooking Issues site, which includes recipes. The Modernist Cuisine series has an in-depth section also. Its recipes have yields between 180g and 1.5kg.

-

It can produce flavors that aren't possible by any other culinary method. You can get distillates, like brandies, with more vibrant flavors than what you get from traditional methods. And the stuff left behind after distilling is often a delicious syrup, one that has no culinary precedent and that can't be obtained other ways. This is just the beginning of what's possible. And no, I don't have one. It's just easy for me to see the appeal.

-

They work great for long cooks. I'm more concerned with very high temperature cooks. I've used them up to 95C, but you can tell the bag and the closure is soft at these temps. The plastic seems to get its strength back once cooled. When doing veggies at the higher temperatures i'm just extra careful when handling the bags.

-

I think a circulator is more versatile, and will also be more precise for the kinds of jobs that require it. Very hard to go wrong with an Anova. I'd suggest starting with ziplocs. Learn the straightforward techniques for using them, and they provide few real downsides for s.v. cooking, and some advantages, like for foods that you don't want to compress (burgers etc). Obviously they are not useful for vacuum functions like rapid pickling, etc.. You can always get a chamber vacuum machine later. I think their attractiveness will depend somewhat on your counter space. For ziplocs, get the quart and gallon freezer bags, and only the ones with out the plastic zipper handle. I've found these 100% reliable up to 95°C. My only gripe is that after freezing food in them, they will often leak after thawing (whether or not they were used for S.V. cooking). For containers, the nice thing with a circulator is that you can choose anything. Here's what I've found most useful: 1) a 12-quart polycarbonate cambro-type square container. I like the Carlsle brand because it's straighter at the top, but anything will work. This is so useful that I bought a 2nd one (they nest). I use these for cooking most things, for bagging food in the ziplocs, and for chilling the bags in ice water after cooking. 2) a 30 quart beer cooler for bigger jobs or longer cooks. Ideally get one that has insulation in the lid (most don't). Remove the hinges and use a jigsaw to cut a hole for the circulator. You can cook for days in this with the energy consumption of a night light. 3) accessories for the above: a roll of Reflectix insulating bubble wrap, cut to sit on top of the water and reduce evaporative and radiative heat loss (most important with the cambro), and, if you like, a rack to keep the bags organized (the one made for the SV supreme is nice, or you can get something from Staples and hope it doesn't rust).

-

You're right, the food processor is easier to scrape the food out of. But you'll never get as smooth a paste. If you're going for a rustic texture it doesn't matter. The blender isn't so bad to clean out if you've got a thin spatula. And for the final cleaning it cleans itself. Fill halfway with a drop of detergent and blast it on high speed. Rinse and you're done.

-

I make nut butters in a blender every week. Almond, pecan, walnut, etc... The big blender makes them perfectly smooth, and does up to 2 pounds at a time. But the 90-second hobart dishwasher ... that's the piece of kit that should inspire all the envy.

-

I'd think a vitamix or equivalent would prove more useful than a food processor for most of the things you've mentioned. They can also do things that nothing else can do. They're not so easy to use if you only want to partially puree something, but a stick blender might be the best of all for that. The biggest disadvantages I've found with the monster blenders are getting the last bits of food out of the jug (I bought a thin silicone spatula just for this, but it can still be a pain), and the noise. When I do anything that needs long blending (nut butters, etc.) I use ear plugs. The cuisinart's mercifully quiet thanks to a much slower motor.

-

Have you tried this in a high-powered blender?

-

I'd agree that a food processor is a pretty low-priority machine, especially if you have a powerful blender for purees and flours. And things that can be done by both a processor and a mixer are generally better done by a mixer. I think the food processor does pastry dough better than anything else. The standard blade cuts fat into flour very efficiently, and does it so fast that nothing has a chance to get warm. And the slicing blade is great for aromatics when you're making stock. It makes short work of slicing a pile of vegetables, in an application where presentation doesn't matter.

-

A few people have said the newer ones are way too big, but I've looked on Amazon and see several models, including one that looks basically unchanged from my 20+ year-old model. This guy breaks down the history and the various models in his review. I can't vouch for the info but he seems to know what he's talking about. I'd just get this model if mine broke.

-

If the newer cuisinarts are truly crappy (no personal experience there) maybe a used robot coupe would be an alternative. I see a bunch on ebay for somewhere between the cuisinart price and the new r.c. price. Maybe budget for a new blade ... I'd think these machines would be a pretty safe bet used.

-

I'm intrigued by the commercial machines, but have never found a task that my 11-cup cuisinart couldn't handle easily. These are simple machines ... a blade at the end of a motor shaft. They don't have the myriad complexities and points of failure of a stand mixer. My only nitpick with the Cuisinart is the safety mechanism that forces you to have the tamper stuck into the chute before it will turn on. I've disabled this by cramming a piece of foam in there, and now the thing is convenient to use. So no Robot Coupe-envy. If it died I'd probably get another cuisinart in a similar size. Mine has lasted since the mid-90s. Light use ... pastry dough, mostly, and also thinly slicing vegetables for stock. I used to use it for more kinds of purees, and making oat flour but those tasks go to the vitamix now.

-

Before reshaping the edge, why not compare its performance to a thin sharp knife you already have? See if the the thinner one requires significantly less force. If it does, compare that one to a sharp knife that has a fat blade. You can see which if any of these factors makes a difference, and potentially save yourself some trouble.

-

I'm not convinced that a thin blade makes a huge difference. If you're trying to cut thick slices from a wheel of cheese that's so stiff that it will actually wedge the knife, then yeah, it probably will. But for most cheese cutting I don't feel much difference between a very thin gyuto or fillet knife and a fat German knife.

-

For cheese, the edge really doesn't matter much. It's helpful to have a fairly robust edge, as Dave suggests, because cheese can be tough and grabby and can damage a very thin edge. But almost all of the resistance you feel when cutting is friction with the side of the blade. That's why shavers and wires work so well ... very little surface area. With any standard blade, and a tough block of cheese, you end up using force. That's why that knife has a handle on both ends. So you can lean on the thing. Sharpening might help a little if it's very dull, but I wouldn't sweat the details.

-

I don't like cutting on poly boards, but it's really just about the sensation. If you're using well-sharpened Japanese knives with an appropriately light touch, there's nothing wrong with them. You're not going catch and edge and chip if you're using the knife properly. Most restaurants, even at the top end, use these things. If I had to use a machine-washable board I'd prefer the sani-tuf rubber ones. These are expensive and heavy and puke-colored, and also require a bit of adjustment to how they feel. But they're very soft and gentle on a knife edge.

-

These knives do need waterstones if they're going to come anywhere near their potential, but they don't have to be expensive ones. There isn't much need for fancy stones until you're experienced enough to have strong opinions on them. By then you'll have worn out your first set and will need new stones anyhow. It's been a while since I've shopped for waterstones, so there could be better values than these now ... but if you shop around I'd suggest a couple of combination stones (different grit on each side, so you get 4 grits) ranging from a 400 or so to 8000 or so. King and Norton are popular value brands. Norton has a kit with two combo stones and a stone flattener. Should be less than $140. Or you can go the Edge Pro route. Much shorter learning curve, but you won't get as fast as you can get freehand. Your stone choice is also limited. I'd strongly suggest doing your first few sharpening sessions on a knife you don't care too much about.

-

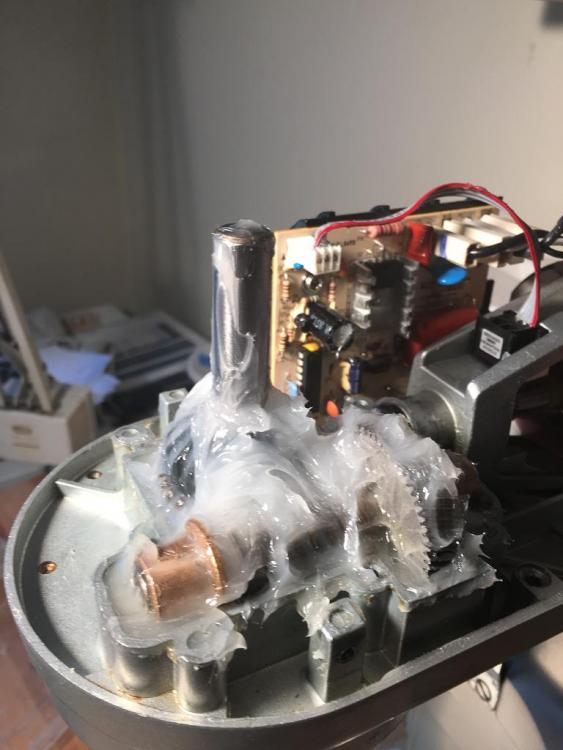

My rebuilt mixer has survived its first few uses, and does seem to run quieter and cooler with the new grease. I think switching to the synthetic grease is a significant upgrade. As is realizing that KA's claim of "lubricated for life" is an insult to the intelligence of every engineer or semi-sentient tinkerer. If you use a mixer hard, you should relube it every few years or so. You might get lucky and get one that survives decades of abuse, but it's not the best bet. One issue with KA mixers is that the transmission is built around a worm gear. These allow huge changes in speed and torque in a compact arrangement. But they introduce a lot of friction, which means added stress and heat for both transmission and motor. I found one study on worm gears that showed an upgrade from mineral oil-based grease (like KA's) to synthetic grease increased efficiency by 15%. This means a reduction in heat produced by both the transmission and the motor. Other benefits include consistent lubrication over a wide temperature range, and much improved resistance to grease breakdown from heat or oxygen or water. No more black goop dripping into the mixer bowl. Unrelated: be very careful not to strip any of the machine screw holes that are threaded into the shell of the mixer, that attach the transmission cover. Some people have done this and had their weekends ruined. Fresh guts with fresh synthetic grease.

-

That's the real deal. I love my Tadatsuna gyuto, but haven't yet graduated to the big-boy knives.

-

And every fish is different. Japanese fish butchery is a great hobby for anyone who eats fish 2 or 3 meals a day, loves knives,and has endless free time. The best resource I now is Ittasan's Youtube page.

-

Another product plug: I really like a product called Howard's Butcher Block conditioner. I used to make my own stuff by melting together mineral oil and beeswax (or sometimes paraffin). The Howard's product lasts much longer. It's a mix of those same ingredients and also microcrystalline wax, which is much harder. With some trial and error you could probably figure out the proportions and make it yourself, but it's not expensive and is just an Amazon click away.