-

Posts

50 -

Joined

-

Last visited

Content Type

Profiles

Forums

Store

Help Articles

Posts posted by Muscadelle

-

-

There seems to be a great fear of working with eggs for bonbon fillings and I have to ask why. As long as the eggs are cooked over 80C to kill any possible salmonella and the AW is adequate, why would it be anymore problematic than dairy? Am I missing something?

-

@EvgenyPI still get them from time to time but I drastically reduced those by not tapping the mold to remove air bubbles when capping. I realized that many of those air bubbles that would come up to the top where created by the air between the shell and mold that was escaping and that’s why I had chocolate slipping in between leaving big streaks.

Sometimes when you look at finished bonbons of Melissa Coppel you can see some small chocolate ring at the bottom too. They don’t have to be all perfect all the time, remember that maaaany photos are edited and that some bonbons that you see on Instagram and such are just pictures of the shell and not the finished product. 😊-

2

2

-

-

37 minutes ago, pastrygirl said:

It's not the cost so much (but for those of us actually trying to make a profit/living, every dollar counts) as how much more plastic waste do I really need to create? Between gloves, plastic wrap, bonbon trays, clear boxes to show them off, and more trays & bags to keep truffles fresh, all the bubble wrap for shipping ... I think I make enough already

How many customers even look at the bottoms? Sure, having your logo or another design on the bottom can make it extra special, but I think chocolatiers are just doing it to impress each other on Insta 🤣

Reading that, I thought some people might like to know that cellulose acetate can be 100% compostable. That’s what I use. In bulk, they are 0.20$USD per sheet. So that’s an additional cost of approx 1 cent per bonbon. They give a nice sleek look and I can fill my bonbon generously 😊

I don’t know if it’s because of the material but even if it gives a perfectly flat bottom, the surface, although not dull looking, never gets as shiny as it would with a plastic sheet.

-

2

2

-

-

Can’t you just tap your bowl/pan full of tempered chocolate for a minute or two to get rid of most air bubbles? I get those a lot in my milk chocolate but not so much in my dark chocolate. It’s a little better when I use cocoa butter to temper, I guess that’s because it increases the fluidity just a notch.

-

8 hours ago, Jonathan said:

So still haven’t gone back to the baklava ones yet, had a new idea and got side tracked. If one were to make a cereal milk ganache, could I directly infuse the cream with the cereal or would it be best to infuse some milk and reduce it and add it. I worry soaking in the cream directly would result in a weird texture if the cereal breaks down

I tried infusing toasted oats in Half cream/ half milk overnight and it resulted in a solid dry and mushy mess. Impossible to extract anything even after warming it up. I don’t know how different cereals could react though...

-

7 hours ago, Jonathan said:

I had something similar happen in a batch of mine but it was a really high fat content filling (hazelnut) so initially I suspected that. However I’ve been taking the step to polish again after the alcohol polish incase of residue and it seems to have made it a non-issue so I don’t know which one to attribute it to? You’re taking a lot more steps to keep your cocoa butter in temper than I am so I don’t know if it’s that

Thanks Jonathan! Those are only the shells so I know for sure the problem is not caused by fillings. I double polish as well! haha glad to see that i'm not so over-zealous after all

I'm wondering if maybe I'm keeping my cocoa butter at a too low temperature. maybe I should keep it more around 30C? I'm using my notes from my Melissa Coppel workshop, but maybe there's something i forgot to write down?

Anybody know enough about Crystals and tempering curve of cocoa butter? I'm wondering if the flecks looks like the result of over tempered CB or maybe CB that went out of temper?

-

I’m really puzzled by some dull or white flecks that appears on some of my chocolates on almost every batch I make. By the look of it, do you think it’s because my cocoa butter gets somehow out of temper when I paint, even though I have a high accuracy thermometer in my cocoa butter the whole time. I keep it around 28.5C.

My molds are always between 18 and 19. I have to say it happens the most often with that technique. (Drop of cocoa butter dispersed by the airstream of an airbrush).

Does it happen to any of you?What would you bet the issue is?

It’s getting very annoying and I’m not sure what to do because most of them are perfectly fine.

Also, I wash and polish my molds with 94% alcohol at every use.

-

-

32 minutes ago, Jonathan said:

I love the first ones! They give a Van Gogh vibe!

Thats what I use for some of my metallic effects:

I'm in love with the copper, it gives such a pretty result! But the one used for the quenelle chocolate (ombre) is the bronze highlighter.

-

3

3

-

-

-

Staying on the same topic (invert sugar)

Has anyone of you ever tried using the syrup from your candied fruits (citrus peel, cherries etc) in a ganache to replace invert sugar?

I'm really trying to do something with all my syrups, it seems like such a waste otherwise.

Do you think that the resulting syrup of candying fruits is in fact invert sugar? If not, is it possible to make it an invert sugar? (by adding acidity and boiling it to 114 maybe?

-

24 minutes ago, Jim D. said:

As Kerry pointed out, the machine cannot read the sample until the it and the sample are approximately the same temperature. It makes sense to me that the sample should be measured when it has crystallized, but, for a filling that eventually firms up quite a lot, it's very difficult to get it into the little cup if you wait, especially since the entire bottom of the cup is supposed to be covered for best results but there isn't supposed to be any of the sample at the top edge of the cup--in other words, the "target" area is quite restricted. I have no scientific evidence about this, but it seems to me that the filling would be at its most "watery" (and therefore have its highest Aw reading) when it is just made. I'll experiment and see if I can get more information.

Thank you Jim! Maybe we could pour the ganache in the little cup when it's still warm so it can flatten out and cover the bottom perfectly and then wait the next day to place it into the meter to get a reading?

-

4 hours ago, Kerry Beal said:

It has to cool at least - it’s reading vapor so warm triggers an error

Interesting! Thank you

-

I have a question for those who own a water activity meter. Do you let your ganache crystallize before putting it into the meter? It would makes sense to me... but i'm not sure

-

Hi everyone,

When I started my business, trying my best to be eco-friendly was a priority. I realized soon enough that it was not a piece of cake to make my ethic works hand in hand with my business.

For reasons like hygiene, costs, standards, it's not easy to make it all work.

I'm creating this topic so we can inspire each other with simple tricks to help our planet!

I just want to be clear, we're not here to shame anyone's practices. I want this to be a safe-space for people wanting to upgrade their eco-friendly game!

Please, feel free to ask any questions, validate your ideas you're not sure about, and of course share all the little things you do you think ca help the environment! 🌱

Let's talk packaging, food waste, ingredients, plastic usage, water usage, etc...

What are your biggest challenges when it comes to eco-friendly practices?

-

6 hours ago, Rajala said:

I made a ganache with 200 grams of white chocolate (37% cocoa butter, overall fat content at 44%), 100 grams of cream (36% fat), 20 gram of glucose (around DE 40), 18 grams of sorbitol and 15 grams of invert sugar (yeah, this came out sweet.) I've been using these ratios with milk and dark chocolates getting a great result in terms of texture - but this white chocolate ganache becomes so soft I can't cap the bonbons.

Any suggestions on how to balance it? I tried adding some extra cocoa butter, but the texture ended up a little grainy - maybe I didn't emulsify it enough though. Maybe just a bit of less cream is the way to go? But how much less?

I made a test with the same chocolate and just cream. No sugars added and it's still a little soft in room temperature, but not as soft. Maybe I've just forgotten that white chocolate ganaches are really soft? 😂

My advice would be to use less sorbitol (half of it) and make sure your ganache is tempered

-

4 minutes ago, Rajala said:

Is there anything one can do about the contraction marks? Or or do I have to live with it? A chef once told me; "a cake always have a front and a behind." - I guess you can apply that to bonbons as well then?

I'll try your suggestion. I'll lower it to 14° when I put them in the fridge next time. I'm gonna do a new test soon. This time going down to 27,5° and heating the molds to around 25-26° just as a test.

I don't know, they do keep happening to me from time to time, but maybe I'll try like really mixing the chocolate between each molds, I've been given them a few swirls but maybe it will help to be more careful. Also, sometimes it's due to my shells being too thin and they can't contract enough to release from the mold entirely, leaving a mark.

-

On 11/28/2020 at 1:19 AM, Jonathan said:

Hi guys, I've started a small chocolate business and have swiftly found the constraints of a home kitchen quite limiting. I also don't quite have the confidence in my work to drop my day job for this yet. Does anyone based in Australia have any advised on how to expand on a small scale? Ideally a rental kitchen would be a good starting point but as I work full time during the week it would ideally only be for 2-3 days/week which is a little awkward.

I'm in the same boat as you, my apartment seems to be shrinking as my chocolate production is getting bigger. Not sure what to do just yet. I hope you'll get some insightful replies.

-

1 hour ago, Rajala said:

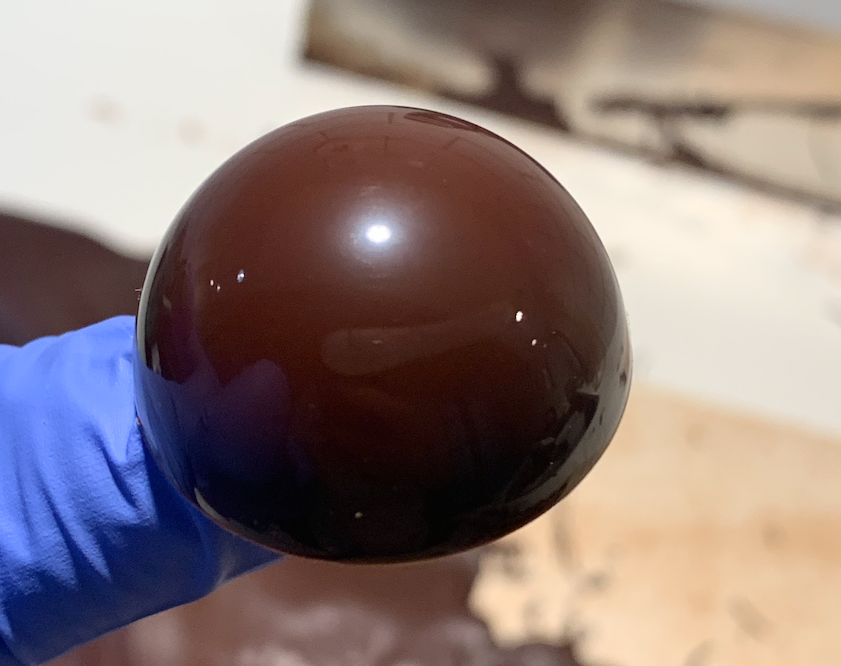

Thanks Teo. I usually never check my chocolate, so I'm thinking that it's not tempered properly now. As I wrote, it's much colder than normal, so maybe I'm off with the temper for some reason here. I just made a new test and went down to 27,5° with my dark chocolate - with much better result. Still 5 of the shells didn't contract successfully. I wish I could figure out why certain shells behave like this. I'm only doing one mold right now, testing things out.What do you guys think about this? That little streak below the spot reflection. It's not a reflection but some kind of mark on the shell. Dirty mold? Something else?

That chocolate indeed seems well tempered. I always work with half-sphere too. That spot looks like a release mark, and it's very tiny. I feel like @teonzo might have pinpointed a very probable cause. Either that or your cooling process may not be fast enough. When I put my mold in my chocolate fridge, I lower the temp of the fridge by1 or 2 degrees so that the cooling system kicks in and there's a nice cool air flow that helps the chocolate contract quickly.

Next time, watch your shells contract from the molds: If you see a tiny spot that sticks, you can be pretty sure it will leave a mark, and it's due to the contraction of the chocolate, not the cleanliness of your molds.

That's all I have! Keep us posted on your results

-

3 hours ago, Rajala said:

So, I spent the night reading all posts in this thread, maybe skimming a few text heavy posts. My question and what I want to talk about, might have been answered elsewhere. But due to my so-so English skills, I really don't find anything good while searching the forum. Please point my in the right direction if you know where I could find an answer.

I've been experimenting with getting my kitchen temperature down to 20°, which works fine, humidity is at around 40% or sometimes hitting high 30s. Which I guess should be fine - if there aren't any issues related with too low humidity that I'm not aware of. The issue I have is that multiple shells really don't contract from my mold at the moment, and I have no idea why - it's not like they're all in the same spots, they can be all over the mold. I've made two tests today with dark chocolate (Cacao Barry Extra Bitter Guayaquil - I had to google that

). With one test I heated up the mold to around 25° before pouring chocolate in the mold, and letting it set in room temperature (20°) - around half of the 21 shells contracted from the mold. With the other test I begun with the same process, but I let the chocolate set in my chocolate fridge at 16°. In this case, only 6 of the shells have contracted as they've cooled down.

). With one test I heated up the mold to around 25° before pouring chocolate in the mold, and letting it set in room temperature (20°) - around half of the 21 shells contracted from the mold. With the other test I begun with the same process, but I let the chocolate set in my chocolate fridge at 16°. In this case, only 6 of the shells have contracted as they've cooled down.

What do you think? I must also say that earlier I just haven't cared about the temperature in the room. It have been at around 22-23°. Can it be that I don't agitate the chocolate enough while tempering it on my counter top? That it cools down much faster with less movement, due to the lower temperature? Should I don't bother with heating the molds? I'm thinking that maybe the chocolate I'm using also have done all the heavy lifting it can do - it's a 5 kg bag I've used for a while and re-tempered many times. Maybe a few too many? People usually state that chocolate can be re-tempered "forever" (okay, I might be reaching,) but maybe there is a limit after all?

Well, I'm going to try some more tomorrow without heating up the mold. Just to see if I get a different result. If I still have problems, I think it's time to open a new bag of chocolate.

You may ask why I even do this when it worked earlier? Well, I just want to try other things I guess - also since people say that 20° is the temperature to work at. 😁

Among the top reasons why shells won't contract are: not properly tempered chocolate and a shell too thin. If you heat your mold before pouring chocolate in it, you may end up with that problem depending on the fluidity of your chocolate. (I work in a room at 18C and I never heat my mold before ''shelling'')

It's important to let your shells crystallize a little bit at room temp before placing them in a cold place. As soon as the chocolate start setting (normally it should take like 2 mins, if it's taking more than that, maybe your chocolate is not well tempered enough) you can place it in a colder place to help the shells contract. Your chocolate fridge at 16C is perfect.

For your next batch, before pouring your chocolate in the mold, make sure your chocolate is properly tempered by dipping a piece of parchment paper in it, place it on the marble countertop and let it set at room temp. If it takes more than 2 mins to set and doesn't have that nice velvet shine, you gotta re-temper, otherwise you will waste your time afterwards with shells that wont come out of the molds.

-

I have a general question for you guys. Is there a minimum waiting time before you pour the chocolate after painting your molds? In fact I'll go ahead and ask: What are the general waiting times in between steps for you. Do you follow a precise guideline?

Personally, I know you have to wait 12 hours for fillings to crystallize and maybe 1 hour before unmolding, but I've never really though about how long I have to wait after painting or how long I have to wait before filling the shells.

-

14 minutes ago, Kerry Beal said:

Try not heating them at all!

Oh! I read that wrong! 😵 Good thing you caught it!

-

1

1

-

-

7 minutes ago, Kerry Beal said:

Shell doesn't look to thin to me. Why not try not heating the shells before capping and see what result you get.

Okay I’ll try heating them a little more! Thank you!

-

28 minutes ago, Kerry Beal said:

The crack appears to be happening where the interface between the two chocolates is happening. Two questions - are you heating your shells before you back them off. Does the same thing occur when you back off in milk chocolate?

Thank you for responding Kerry!

Yes I do heat them before capping. I almost never use the same type of chocolate for shelling and capping so I'm not sure...but most of them turns out just fine.

I feel like the shell is not that thin either... could it be a filling that is too soft even when fully crystallized?

Water Activity/Shelf LIfe

in Pastry & Baking

Posted

I was away for quite a while and I can't believe I've almost missed this. Thank you so much for sharing all your experiments! This issue had been puzzling me for so long. You are the real MVP