rbm

-

Posts

43 -

Joined

-

Last visited

Content Type

Profiles

Forums

Store

Help Articles

Posts posted by rbm

-

-

Shouldn't be a problem to regrind the tip. The easiest and least disturbing to the edge geometry is to regrind from the back of the blade rather than the cutting edge. If you don't have a grinding machine yourself, enlist the help of a friend with one or a professional machine shop. Reshape the back edge so that it gracefully meets the cutting edge at a point again, but lower down the edge than when it was new. So now, your 10 foot Shaaf will only have a 9 foot - 11 15/16 inch blade.

TIP: Only use aluminium oxide stones (white), not carborundum (grey) as the latter will quickly heat up the tip and ruin the temper in the metal. Also, if at all possible, use a slow RPM grinder (1725 RPM) instead of a high RPM machine (3250 RPM) because the lower RPM machine will keep the heat buildup in check and save the temper on the edge. If you haven't a choice, use a very light touch and cool the blade often. If you get a slight blue tinge to the metal after grinding, you've ruined the temper and the blade may have to be rehardened.

-

A mirror edge means the metal at the point of meeting is smooth. The advantage to a smooth edge is that it is a sharper edge that will last longer.

Much of the advantages and disadvantages to the two schools of thought are covered very thoroughly in Chad's Knife Sharpening Tutorial. I am a proponent of the smooth edge school because of my woodworking background.

When you rub metal on a sharpening stone, you scratch the surface, creating a ragged edge where the two surfaces meet, much like a microscopic serrated steak knife. As you cut through food (or wood in the case of woodworking blades), you break off the teeth causing the blade to go thick and flat, i.e. dull. The surfaces on a mirror finished edge have no microscopic serrated teeth, therefore there are no teeth to break off, therefore the blade parts the cells of the food/wood cleaner with less effort on the part of the user and the edge lasts longer (i.e. won't go flat and thick).

The life of the edge is dependant on the bevel between the two surfaces (how much metal is backing up the edge), the quality of steel used on the edge (wear resistance is related to brittleness of the metal), the pressure applied to the edge during use, the resistance offered by the material being cut, and the clearance angle between the work and the cutting edge and the way the edge is offered up to the work (a sawing motion vs. a planing motion). As Chad points out, sharpening is optimizing performance under a given set of conditions. You are balancing several performance factors -- the ease of use vs. life of the edge vs. time required to reestablish the edge when it dulls. The design and performance envelope of the knife, the metal used in its execution and the way the knife is used will all effect this performance balance. If you exceed the performance envelope of the knife (for example, cut a bone using a Japanese usuba hocho), it will catastrophically fail -- the edge will chip.

-

thanks again for the updates rbm.. actually I only soak the stones in water when I'm ready to use... should I have them in all the time, what happens if I don't?

Nothing actually happens to them if you store them dry. They should soak at least 1/2 hour before use. If they are stored in water, then you save that half hour. If not, no damage occurs to the stone. Don't store 6000/8000/12000 grit finishing stones in water as they should be stored dry and water dripped on them when you use them (like with a baby bottle or spray bottle).

-

PJ,

I am a bit obsessive about my hand tools. I know what you mean when you work wood with a perfectly sharp blade. I own a 1914 Norris A13 smoother. What a plane! I'm talking woodworking porn here!!

Check out this picture of the plane blade.

Check out this picture of the plane blade.

A massive blade, razor sharp edge and paper thin mouth (0.5mm). You can even see the reflection of the camera in the blade. With that beauty, I get tissuepaper thin shavings from even the most difficult woods.

If you want shavings that look like chocolate, try planing wenge (aka. pango-pango). It's a deep, dark brown African hardwood with lovely tan streaks in the elongated cells of the wood. It looks exactly like rich dark chocolate!

-

Hi SG,

Don't obsess about the angles! Like Obi-wan says "Relax! Use the force, Luke". Really!!! You will be really surprised at how much leaway you have with sharpening angles and how accurate you can hold an angle without using a guide. Guides like the one Sam recommended are fine for a while but IMO they take time to setup and get in the way. You'd probably laugh if you were a golfer or tennis afficiado and saw someone using some mechanical machine to maintain their swing, right? That's why you hire a trainer when you're a beginner -- to give you the confidence to memorize the way your muscles should be placed for a perfect swing. After a while, you discard the trainer because your muscles have been programmed with the correct positions. The same goes for sharpening. After a few sharpening sessions, your muscles know the correct positions to assume.

First off, maintaining the correct angles for single bevel knives is a no-brainer! Just keep the edges flat to the stone. The manufactured angles will determine the sharpening angle. You only have to worry about angles if you want to put a microbevel on the edge. But this is obsessive, IMO.

As for westeren style knives, I read the Korin site info just now and they recommend setting the height of the back of the blade two US pennies above the stone. Personally, I use my thumbs to gauge the height. I assume two positions when sharpening.

The picture above shows the position of my hands when I'm sharpening the lower half of a large knife or a small knife. My right hand grips the handle and holds the angle. My thumbs gauge the height above the stone and the fingers of my left hand maintain pressure on the edge. I lock my wrists once the setup is complete (done in seconds!) and then sharpen from my elbows and shoulders with a smooth back and forth movement. My thumbs now serve the purpose of steadying the blade as I move it back and forth over the stone.

The picture above shows the position I assume when sharpening the tip of a large knife. My thumbs still gauge the height above the stone and fingers maintain the pressure. Though it is very hard to see from this angle, my right hand baby finger is curled around the handle to hold the angle and allow me to move the knife laterally across the stone. As I approach the rounded part of the edge near the tip, I lower the angle to the stone slightly. This has the effect of maintining the same included angle along the entire length of the blade edge.

Since I've invested a lot in different waterstones, I bought a ceramic flattening stone to keep them in tip-top condition. The stone used to be available from Lee Valley Tools but they don't have it in the 2003-4 catalog. But, I see that Japan Woodworker carries it. The flattening stone looks like this:

The channels help with the cutting action and carry away the waste swarf. This is equivalent to a 100 grit waterstone. Since this is a pretty expensive item (USD 75) you can get equivalent results by glueing silicon-carbide sand paper (also known as wet-n-dry) glued to a glass plate. Use 3M spray adhesive to glue the paper. Use 120 grit paper for course stones, 220 grit paper for medium stones and 320 grit paper for fine stones. The paper is reusable two or three times. You can either use the paper wet or dry depending on whether the stone itself is wet or dry. Normally, you should be storing your stones in a bucket of water anyways. You are doing that, aren't you!!!!!

I've read in some woodworking forums that some people use a Leca-block (light concrete building block) to flatten their waterstones but I've never tried this myself.

I've never had problems with sharpening stainless steel on waterstones. I've never read this either. I tried to find your reference on the Korin site but failed to find it. So, I can't really comment except to say that I have not had any bad experiences sharpening my Henkel stainless steel knives on waterstones and I've been doing it for years.

- Robert.

-

If you want to see serious recipes that use the special features of microwave ovens, check out Heston Blumenthal's article in the Guardian for 18 Oct 2003. It's online at the Guardian's web site and is called "We have Blastoff!".

The stuffed profiteroles are absurd! Frozen on the outside and piping hot on the inside. Serve these for desert and have your guests wondering how you did it. But it's all explained in the article. Check it out.

- Robert.

-

Hi,

It's been pointed out on the eGCI knife tutorial that there are two schools of thought when it comes to sharpening knives. One school supports the view that the edge of the knife should be razor sharp. The other school that the edge should be rough, much like a serrated blade. I am a staunch supporter of the first school of thought, mainly because I'm involved with woodworking as a hobby. Woodworkers strive to attain a razor sharp edge on their hand tools so that working wood is safe and easy. A razor sharp plane just glides effortlessly through any wood. I've taken that philosophy to the kitchen and keep my knives razor sharp.

Waterstones will quickly produce a razor sharp edge if used properly. You can get a mirror shine on the blade which is the prime indicator of a sharp edge and you can keep that edge sharp with just 30 seconds of attention to the blade periodically, when you feel the edge has dulled. It's not hard to do if you know how.

I took some photos of my sharpening session when I recently purchased a Japanese usuba hocho knife. I went through the complete flattening and sharpening process and took photos so that others could get an understanding of what's involved when using waterstones to attain an cutting edge.

In woodworking, blades are usually single bevelled. That is, one side of the blade is flat, the other angled to it. Japanese knives are manufactured this way. Western knives usually are double bevelled with two sides of the cutting edge angled relative to each other. The goal when sharpening a single bevel edge is to get the flat edge DEAD FLAT and polished to a mirror finish. Only then, can you possibly begin to shape the angled side to get a sharp cutting edge.

There are a number of grits of waterstones available. The higher the number, the finer the stone and therefore closer to the mirror finish you will get. I personally own three waterstones; a 600/1000 combo, a 4000 and a King brand 8000. The combo is for reshaping blades, for removing nicks and for reshaping the points of worn knives. The 4000 is for flattening and removing scratches produced with the 1000. Finally, the 8000 is for finishing. In addition to the waterstones mentioned above, I own a 350/600 DMT diamond plate. A diamond plate is a nickel plated steel plate with industrial grade diamonds imbedded in it. This I use for rough grinding the flat surface because it works very quickly and is itself dead flat so I know I can skip the 1000 grit and move over to the 4000 directly, working with a properly prepared surface.

Waterstones work because the stone wears at the same rate as the steel being sharpened. The downside to their aggressive sharpening quality is that they must be constantly retrued, that is made flat. You can buy a special truing stone or you can use a lower grit stone to flatten a higher grit stone (a 600 to flatten a 4000, for example). You have to check the flatness of the stone often and correct it.

To sharpen a knife to a razor edge, I use the following procedure:

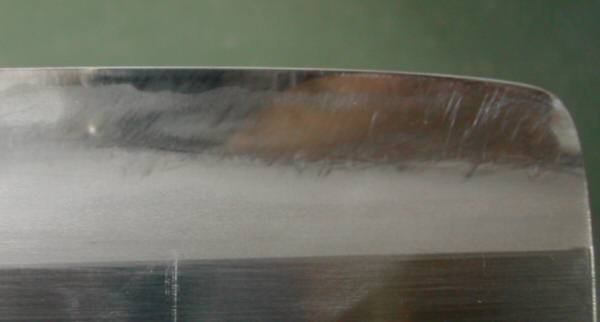

I started off using the DMT diamond plate to reference the flat edge of my knife. About 1 minute of grinding showed me that the blade was flat and I moved over to the 4000. The indication of a flat surface is that the grinding pattern is uniform over the surface; depressions will show up as shiny spots. I spent about 3 minutes or so grinding on the 4000, trying to get a uniform mottled grey tone along the cutting edge of the blade. I concentrated all the pressure on the edge of the blade using both hands and applying lots of pressure. I like the stones to be secured on a bench and at eating table height so that I can use my upper body to bear down on the blade. I use just a little water. The idea is to create a slurry much like a paste from the worn particles of waterstone. It's this slurry that does the cutting and why a waterstone wears so quickly. The edge looked like this when I was finished:

When the back of the blade is done, then I move to the front edge. I don't use any jigs to hold the blade at the proper angle when sharpening. You tend to get a feel for the proper angle and your muscle memory will end up being just as reliable or more reliable than some fancy gadget. Besides, the setup time of the jig is so long. I'm targeting for the same uniform grey appearance and feeling for no burr along the cutting edge. You can feel the burr if you drag your finger nail over the backside of the blade. If there is a burr, alternate sides, drawing the knife blade over the waterstone as if it was a stropping leather. Alternate sides and maintain proper angles at all times. After a couple of passes, the burr will disappear. Then I moved over to the 8000. The 8000 produces the mirror finish and a razor edge. My grinding setup looks like this:

The small white stone is called a nagura stone. It is used before sharpening to produce the slurry on an 8000 grit stone. The baby bottle contains water. Don't use a lot of water on the 8000 and that's why I have a baby bottle -- to control the amount of water I use on the stone. It just needs a few drops. Rub the nagura over the surface until the waterstone is covered in a brown sludge. Then start sharpening. The 8000 will not cut as fast as the 4000 so I spend about 5-10 minutes getting the mirror edge. It's pretty messy but this picture shows the all important slurry:

In the picture above, you can see the impressions where my fingers have been just along the edge of the knife. I use a lot of pressure when grinding, bearing down on the blade with my upper body. Make sure the stone won't move. I use carpet anti-slip padding, a sort of rubber mat with holes to hold the stone stationary. When the edge is polished, it will look something like this:

You can just see the reflection of my thumb in the knife as I took this picture. Once this edge is produced, maintaining it is easy. You don't need to go back to the 4000 unless you've damaged the edge. Just 15-20 seconds per side on the 800 will bring back the sharp edge again.

I know that the magnolia wood used in Japanese knife handles is water resistant but I still soak my handles in tung oil overnight. Then I wipe off the excess and let it dry. A coat of wax applied with 0000 steel wool completes the handle maintenance.

Although I've gone through what's involved in sharpening a Japanese knife, the same principles can be applied to Western knives. I have sharpened all my knives on waterstones to a mirror finish. Here, for example, is my 250mm Henkel:

Although this photo doesn't show it closely, the edge of this blade is mirror sharp. I can take any of my knives and cut through a newsprint page effortlessly. In fact, my heavier knives can do it using only their weight. It's an impressive demo.

I hope this is helpful to those of you who aren't familiar with waterstones.

- Robert.

Sharpening with waterstones

in Kitchen Consumer

Posted

I don't own any globals myself so I can't comment on the bevel on the backside of the blade. If there is a bevel, it would end up giving the edge a more acute angle with more metal behind the edge than a traditional Japanese single bevel knife. This would increase the life of the edge at the expense of harder use. The same can possibly be said of your Misono but since I don't own one, I can't be 100% sure. This backside bevel is a design decision to optimize the life of the edge for the majority of users (who generally abuse their knives).

I checked out Google and found the following post a newsgroup:

I read in another post that manufacturers of western style knives use an 18 degree angle. Thus, you see that you have some leaway in how you grind your knife. The steeper you grind, the more metal you'll have backing the edge with longer edge life but at the expense of ease of use and straightness of the cut. Double beveled knives tend to wander through the cut whereas single bevel knives cut straighter and with less effort. I probably wouldn't go over 25 degrees.

This 22 degree angle on the Globals should probably be maintained since that was what was intended by the designer. You can visualize a 22 degree angle by taking a piece of paper and fold it diagonally corner-to-corner three times. Each time you fold it, you halve the angle (90,45,22.5). Use it as a gauge to visualize how far above the stone the knife back should be maintained.