douglai,

I had similar problems, but with excellent help and service from HR, our FD is back up and running properly now.

We purchased our FD in Jan 2016 and used it successfully, and nearly continuously, until April when we started exhibiting very long batch processing times. Initially, we could finish a batch in 24-30 hours depending on the type and quantity of food in the batch. The processing times got longer until they were 50 hours or longer and on several occasions, the food never dried properly. The freeze stage always performed properly. My problem was in the drying stage . I watched the temperature and pressure on the screen and observed symptoms similar to those you described. In particular, the temperature would be essentially constant at about -20F and the pressure would hover somewhere above 500 mTorr. As THXCMark pointed out in a separate post, the pressure typically will cycle between 500 and ~900 mTorr during the drying stage. At first, I suspected a problem with the heaters because they did not come on and therefore, the food didn't dry. But the problem was that I had a vacuum leak. The heaters are controlled by the computer (in the HR FD) and are not commanded on until the pressure gets below 500 mTorr. When they turn on, the ice in the food sublimates, water vapor is captured on the chamber walls as ice, and the pressure rises (as it should). When a max temperature threshold is reached, the heaters are turned off and the pressure is pulled back down to 500 mTorr and the cycle repeats. The pressure in my FD was not getting down to the 500 mTorr threshold (due to a vac leak) so the heaters were never switched on by the computer.

I had several phone calls with the service department at HR and the techs were all very helpful. They had me pull the logs from the FD and email them to HR so they could help diagnose the problem. The log is a csv file (comma separated value, plain text file) that can be imported into a spreadsheet. It contains the minute-by-minute details of pressure, temperature, heater status, and the mode in which the FD is operating. The following table contains the first few rows of the csv file from a successful (nominal) freeze drying session.

TimeStart

TimeStamp

Pressure

Heater

Heater State

T1

T2

T3

T4

Heater Secs

Stage

P

I

D

B 006-1

B 006-1

3/12/2016 12:25

3/12/2016 12:25

5000

0

0

76

--

--

--

0

Drain

0

0

0

1

42441.51806

5000

0

0

76

--

--

--

0

Freeze

0

0

0

1

42441.51875

5000

0

0

76

--

--

--

0

Freeze

0

0

0

1

42441.51944

5000

0

0

75

--

--

--

0

Freeze

0

0

0

1

42441.52014

5000

0

0

75

--

--

--

0

Freeze

0

0

0

1

42441.52083

5000

0

0

74

--

--

--

0

Freeze

0

0

0

1

42441.52153

5000

0

0

73

--

--

--

0

Freeze

0

0

0

1

42441.52222

5000

0

0

71

--

--

--

0

Freeze

0

0

0

A table of numbers can be pretty dry, but if you plot the data, it looks like this:

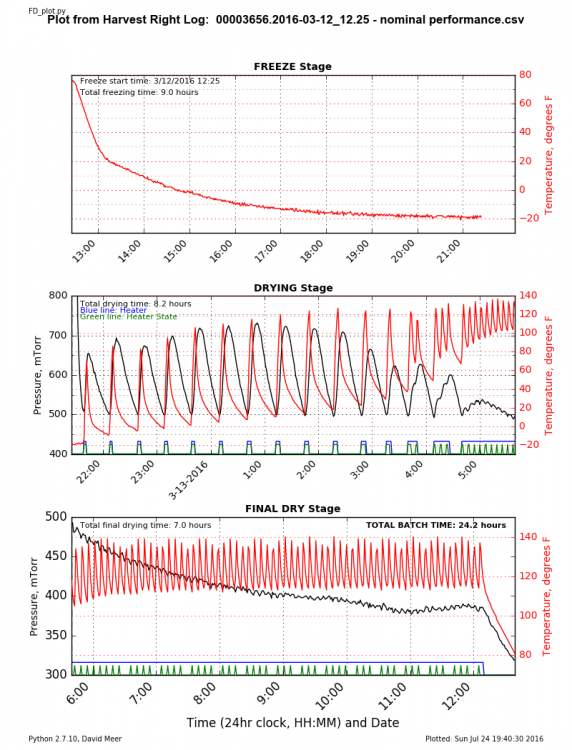

These plots have been useful to me to show how well the system is working. There is a subplot for each of the three stage types. The total batch time was just over 24 hours with the default 9-hour freeze stage and 7-hour final drying stage . Pressures are plotted in black and use the scale on the left. Temperatures are plotted in red and use the scale on the right. The heater is enabled when the blue line on the bottom of each plot is high. The heater is actually on when the green line is high. During the drying stage, note that the heater does not get turned on until the pressure drops to 500 mTorr and it takes about 30 minutes for each temp/pressure cycle during the stage. Also note that the pressure during the final dry stage typically stays under 500 mTorr.

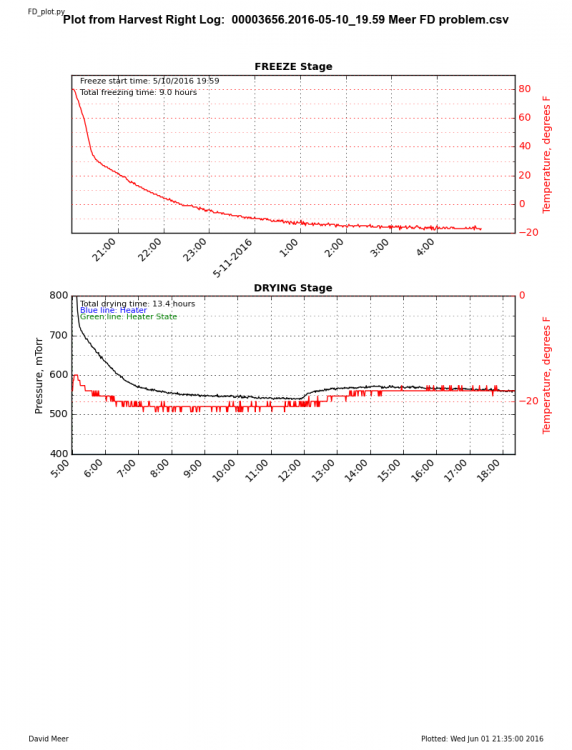

When I had my vac leak problem, my plots looked like the following:

The freeze stage went fine. However, during the drying stage the pressure never got below 500, so the heaters never came on and there was no freeze drying happening. There is no subplot for the final dry stage because the FD never switched over into final dry stage.

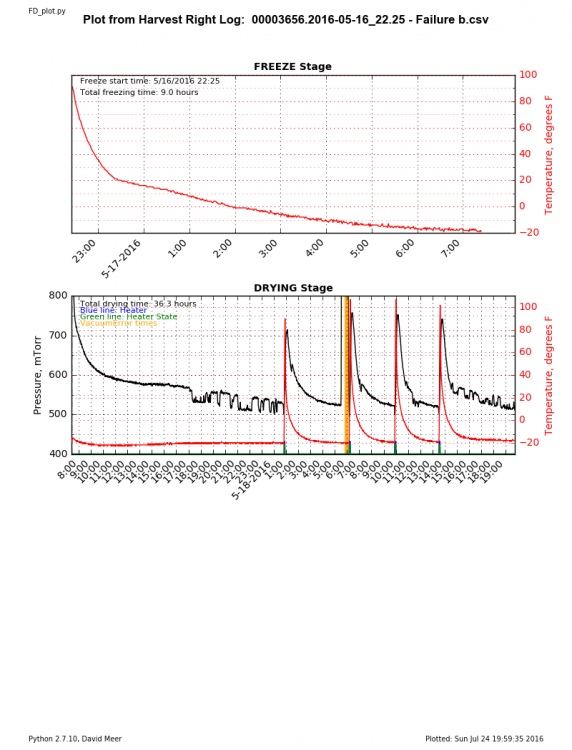

During a separate failed attempt to process a batch, the results were as shown in the plot below:

Again, the freeze stage was fine, but the FD took 17 hours to pull the pressure down to 500 when the vac pump turned on at 8AM and there were only three more cycles completed before I turned the FD off because it clearly was not working properly. These three cycles took an average of about 4 hours each instead of the nominal cycle time of 30 minutes.

I worked through a series of diagnostic steps with the techs at HR to ensure the various vac connections and the hose were not the problem. HR then suspected that the problem was with my door gasket and a replacement gasket solved the problem. There was no smoking gun test result that pointed specifically to the gasket as the culprit, but the other tests narrowed down the possible causes.

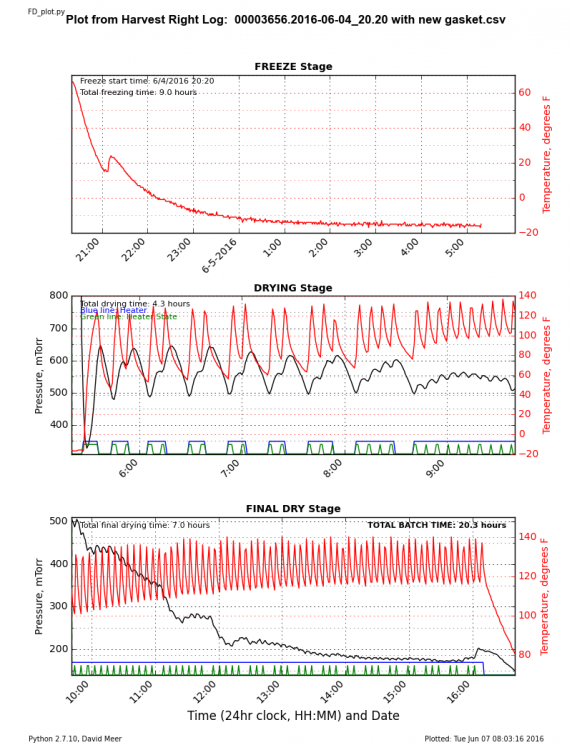

I installed a new gasket and now I'm getting performance like this:

It's interesting to see that the details are different from the first (nominal) plot, but the overall characteristics, thresholds and times are similar. (The "bump" in the temperature just after 9PM in the freeze stage was caused because I pre-chilled the empty FD for an hour before I opened the door and inserted the trays of pre-frozen food.)

So, a long story about my problem and its cure ... back to your question. The problem you described sounds a lot like what is shown in the second plot in which my FD never got down to 500 mTorr due to the vac leak. My leak was caused by a faulty gasket, but unfortunately, there are several other fittings and components where a leak could occur. I encourage you to contact HR tech support and work with them to determine how to fix the problem.

BTW, HR emailed me directions for downloading the logs. There may be different procedures on other HR FDs, but on my FD, I turn off the power, insert a thumb drive into the USB port on the right side of the FD, then turn on the power. Watch the screen. When it's finished downloading the logs, you will see the regular screen appear. You then just remove the thumb drive and move the files to your computer for review.

Good luck.

Dave