EMG

participating member-

Posts

38 -

Joined

-

Last visited

-

Buy a counter-top 18-bottle analogue wine cooler (Danby coolers go as low as 6C). Make sure your water bath and circulator fit inside the wine cooler with the racks off. Have a timer setup for shutoff 15-30 minutes before the circulator turns on. Voila! lol. There's your complete DIY fully automated sousvide setup. Too much messing around for my taste though.

-

I'm more interested about the 1500 watt heater. I just sent Vacmaster an email asking them circulation rate and lowest temperature setting. I have an Anova. Love it! I mostly make home made cheese with it. The 1000w heater on the Anova is great, but not powerful enough to make "Thermophilic" cheeses like italian and swiss cheeses. To make those, I have to "cheat" and add hot water to the bath. A 1500w circulator would be a charm!

-

The problem with sous-vide is the word "sous-vide". Even in french it doesn't mean much and needs an explination on why it's such a great cooking method. This is a problem if you want to sell to the general public, there's a whole lot of misconceptions about what sous-vide cooking is. How many time I've heard a person say "isn't that the cooking method where you boil your food?" Anova is rebranding the term with "Precision Cooking". This term is much more self-explanitory. The potencial of precision cooking is HUGE! a precision cooker has the potential of being just as common as the microwave. It's that appealing! So why isn't it picking up yet? Marketing. Rebranding from "sous-vide" to "precision cooking" is a step in the right direction.

-

I'm real glad they added the 2-pack pledges! I just pledged $230. That's $115 per unit, pretty darn good IMO!

-

Congrats on such a quick Kickstarter success, Jeff! Will you still be selling the old units when the new one is launched? I`m asking because I really like the one I bought last Fall, the 1Kw heater and 12L/min circulation are important features for the type of use I need it for.

-

-

I built the curd cutter myself. I posted the instructions on how to build one at a cheese making forum. I'll post a pic. I'll also include a pic of the whole vat setup disassembled. I made a caerphilly cheese yesterday, it's sitting in the brine for a few more hours and then will age for about 8 weeks. Next weekend, I'll make a Jalapeno Jack.

-

Over the years, I've dropped my cell phone in a puddle of water twice. Both time I immediately took off the battery and sealed it in a ziplock covered with uncooked rice. Let the rice absorb water in the device for 48 hours undisturbed. It worked both time. Maybe this could be done with a circulator that was dropped in water.

-

$70 sounds like a lot for shipping, but it only comes down to $44 if you exclude the included HST. So it's not bad at all. Plus, you get it 2 days later.

-

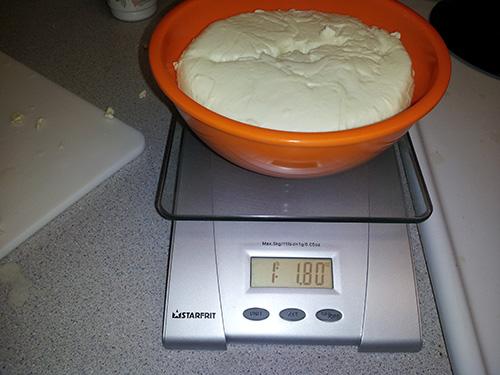

I made some mozz yesterday using the sous-vide setup. It went really well! Adjusting the temperature every 5 minutes during the "cooking" step was a bit tricky though. When I did the "water" test a few weeks ago, I didn't factor in that the milk becomes a solid. So there's a slight learning curve there. I also over acidified the cheese, but that was my own fault. I put the curd mass in the refrigerator to finish it the following morning (the cold slows down the acidification), but I put the curd in the fridge when it was still too warm, so it probably still acidified for an hour or so in the fridge. I was still able to pull a stretch for the pasta filiata though. The taste test passed. It's smooth, creamy and squeeky and is developing a nice piquante flavor since I added lipase (an enzime that gives an italian taste in cheese. Takes a day or two to kick in) All-in-all, this was THE easiest cheese batch I've ever made. The circulator really simplifies things when making cheese! Sorry for the lack of pics... here are a few:

-

I only bought 2 infomercial kitchen gadgets in the past and I rather like them both: Magic Bullet: I don't use it as much as I used to, but I still make smoothies out of it. That's about it though. Geoge Foreman Grill: Used it a lot for about 4 years. Recently threw it away. Will not replace. I sous-vide and then sear meat now, countertop grills are a thing of the past

-

Yes, raw milk makes a richer cheese. The second best milk source (if raw is not available) is low-pasteurized/non-homogenized milk. Homogenization is the worst possible thing that could be done to milk. Almost all commercial cheeses are from pasteurized/non-homogenized milk. As consummers, we are quite used to the richness in that taste range. A lot of home cheese makers will start out doing cheese with store bought milk (pasteurized AND homogenized). Those cheeses lack richness and quality. But once a home cheese maker uses a better milk source, the cheese has a real good chance to be even tastier than commercial cheeses, depending on the cheese makers ability to make a consistent batch of course. Cheese can only be as good as the milk source will allow, the rest is up to the cheese maker.

-

Nice! What I like about SousVideMagic is the fact that you have no limit on the size of your vat. You can easily devise a 40 gallon vat. You'd only need a restaurant style SS sink on legs and a barrel warmer strapped around it and plugged into the SousVideMagic. I'll certainly consider a PID or SousVideMagic if I'm compelled to bring my cheese making hobby to another level.

-

It takes quite a bit of experience to become a good cheese maker. It's really rewarding though! Here are the basics of making a typical cheese (you'll see why a sous-vide device facilitates cheese making). this is just an example: 1. Bring milk temperature to 88F 2. Add culture (can use buttermilk or yogurt for this step) and let sit at 88F for 45 minutes 3. Add calcium chloride 4. Add coagulant (rennet) and let sit at 88F for 45 minutes to 1 hour 5. cut the curd mass in 1/2 inch cubes and let sit at 88F for 10 minutes 6. Raise temperature by 2F every 5 minutes until you reach 102F, stirring the whole time. 7. Empty the whole content of the vat in a colander. Only keep the solids (curd), discard the liquids (whey). 8. return the curds (now a slab) to the empty vat and keep at 102F for 40 minutes, turning the slab of curds every 10 minutes. 9. .... There are other steps in order to finish the cheese making process, but these first 8 steps are the ones involved with temperature control in the vat. This was just an example. A lot of cheeses have the exact same ingredients, but they slightly differ in the making process. It's quite intriguing how milk mixed with a bit of buttermilk and a coagulant can have so many different results.

-

Problem with my setup solved! I got some hooks from Ikea, peeled off the foam backing and inserted a 1/2" dowel cut to the right size. Now I just need to hook 2-3 lbs on each whenever I need to keep the vat from floating.