sarah72

participating member-

Posts

16 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Any tips for moulded chocolates in hotter weather? Normally have no problems with them coming out of the moulds but my kitchen is a constant 73-75 F at the moment and I've suddenly got cocoa butter sticking to moulds and bonbons not releasing without time in the chiller. After painting moulds i normally just let them set up at room temperature and that works fine when the room is at 66 F. Do I need to chill the cocoa butter after painting when it's hotter? Thanks x

- 22 replies

-

- Confections

- Dessert

-

(and 1 more)

Tagged with:

-

Thanks everyone for the replies. Did a few more tests with the bars and think you're right about having to close them before the first layer has released.

-

Hi all. My chocolate bars are usually pretty basic, just chocolate with nuts or other flavouring sprinkled on top. Yesterday I had some homemade shortbread lying around and thought it might be nice in a bar. I wanted it to stay crunchy so broke it up and mix it through the chocolate rather than having it on top and exposed to the air. I just did a small amount to see if it would stay crisp, and poured it out onto some parchment. This morning the top looked perfect, but when I turned it over the bottom was covered in oil. It looks like the shortbread pieces sank and created pinholes in the chocolate where they touched the parchment, then when the chocolate contracted it must have squeezed the fat out of the cookie pieces and through those holes. The result was a very tasty snack for me but if that happens on parchment I guess it would do the same if I tried it in a tablet mould. I'm not used to mixing inclusions through my bars but I'm trying to do some more interesting flavors and was hoping this would be one of them. Is this a common problem with high fat inclusions? Is there any way it can be prevented? I also tried to do a caramel filled tablet and it was a disaster. I treated it like a bonbon mould and tipped out the excess chocolate to form a shell, then filled it with caramel and left it overnight before capping it off. The cap seemed to contract so much that it bent the whole bar into a crescent shape! I was planning to do some with caramel and some with praline like tablets I've seen from French chocolatiers, but how do you get them to stay flat? Any advice would be much appreciated! Thanks x

-

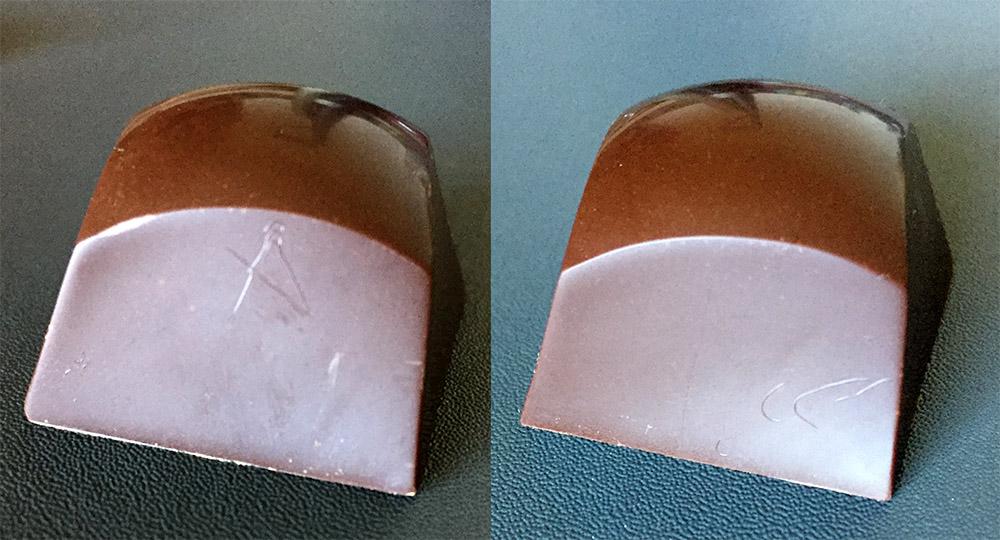

Glad to hear they got your problem sorted out. Unfortunately I'm having some trouble. Chocolate World have looked at the picture I posted here and their response was that those marks are caused by "hairlines" in the polycarbonate which they said were an unavoidable part of the manufacturing process when you have a flat surface such as the ones in that shape. That seemed a bit far fetched given that I have tons of moulds from them and other manufacturers with no such issues, and the marks are exactly the same in each mould. I'm just going to get a refund on these as they said that any replacements they sent out would have the same issues, so apparently they are happy to sell moulds with manufacturing defects

-

Thanks for all the feedback and support. I was honestly starting to think that I was being unreasonably picky, so it's great to hear that I'm not!

-

Resurrecting this topic because I've just had another shipment of moulds directly from Chocolate World and for the second time in a row I've found scratches in the moulds. Along with a number of small blemishes randomly throughout the moulds, there are a couple of marks which appear in the same place on each mould of a particular design. I contacted the agent I buy them through who said that they only send back around 5-10 moulds per year, so for me to get this many problems back to back is unheard of. They actually downplayed the problem, and suggested that these small marks might just be a fact of life. They even went so far to say that if the moulds aren't up to my standards then Chocolate World "might not be the company for me", which I can't believe is true as just about every chocolatier seems to use them. To make sure the marks I was seeing were actual scratches and not just marks in the polycarbonate, I cast one of the moulds in dark chocolate and have attached a picture of result. The "A" shape mark on the left and the series of "C" shaped scratches on the right are present in the same place in every mould I received in this design, so it's clearly a manufacturing fault. There are also a number of similar marks in random spots on each mould. The simple question is: are small defects like this "normal" and I'm being too picky? Or should these be going straight back to Chocolate World? Would be grateful for any advice as this is driving me (and the agent I bought them through) insane. Thanks x

-

Thanks for the advice, glad to know it's not just me being picky. I got in touch with them again and apparently there was a problem with that batch, so back they go!

-

Hi all, I just received a box of shiny new chocolate moulds from Chocolate World in Belgium, but while giving them their first clean and polish I noticed that a lot of the cavities have light scratches in them. I contacted the manufacturer and they asked for pictures, but the scratches are hard to pick up on a camera. I don't have a huge amount of moulds as my business is tiny, but I've not had this problem with moulds from other manufacturers, or even other Chocolate World moulds I have. The moulds in question are model 2207 (I think a lot of people will be familier with that one as it's a popular dome shape), and I'd say accross all the moulds I received, about 1/4 of the cavities have some sort of light scratch or imperfection. I'm being super picky here, the scratches are very light and a lot of them are at the base so won't be too visible on the product, but you can definitely see and feel them in the cavities, and I don't want that appearing on my chocolates. Has anyone else experienced this problem with Chocolate World moulds? Is it something you just accept or should these be going straight back? If it was just 1 or 2 cavities/moulds I'd pass it off as random scratches and return them, but being so frequent on all the moulds I received has thrown me a bit and I don't know what to make of it. Thanks, Sarah

-

I've tried using the formula from Morato's book, it's pretty difficult to hit his targets some times. It does give good shelf life, in that I've had bonbons filled with a ganache which fits the formula sat on the side for over 3 months with no mold or significant shrinkage, and they have maintained a really good texture. The biggest problem I find with his formula is that for me it generally produces a thick, mayonnaise like ganache which wont settle flat when piped. I've not figured out how to fix this yet and often end up having to scrape peaks off before capping, and my bases end up being thicker at the edges. Because of that I only use the formula when I need ganaches to last a long time, as you can still make a great tasting ganache, but I do feel like it trades off some quality for shelf life.

-

I'm really interested in the pipable "gel" PDF. I saw something (maybe on this board) about blitzing the PDF with something like 10% additional puree, but I'm with Jim on worrying about what this would do to shelf life as I can't see the set PDF dissolving into the puree enough for the sugar to preserve it. I've tried just lowering the amount of pectin I use and not cracked it yet. The other thing I thought of was to not cook it as far but again this might cause shelf life problems.

-

With high cream, low sugar recipes like the one I listed in my previous post, I notice that after 2 weeks the ganache feels firmer presumably due to drying out with there being so much free water in them. After two weeks they start tasting a little less fresh, and if I start going over 3-4 weeks some can start pulling away from the shell inside and start getting moldy. These problems all go away with the recipes I've adapted to have less water and more sugar, but I can't get them in the shells effectively. I'm starting to think the only way I'm going to get around the shelf life issue with dark ganaches is to slab them and dip rather than mould.

-

Bit confused here, did you mean less liquifiers than I'm currently using? My adapted recipes for dark chocolate ganaches all set up quite firm, I don't have as much of a problem with milk or white, it's just the dark ones giving me trouble. My old recipes with low shelf life just use invert, for the ones where I've tried to extend the shelf life I've used a combination of invert, glucose and dextrose, which I've tried to balance to avoid the negative affects of each sugar while not imparting too much sweetness overall. So far I've avoided sorbitol, I know it's popular and the best thing for lowering water activity, but it always struck me as too close to a preservative, although I suppose if I've got to the point of using dextrose I'm already into "weird sugars" territory and should probably reconsider that stance. I've never come across the trehalose that Keychris mentioned. I had that exact problem with this technique the first time I tried it! Only works with moulds where the shape of the cavity stops the shell from shifting when you scrape. I try to aim for very thin shells as this is what is considered ideal for high quality handmade chocolates in my area, so a completely flat 1-2mm base would be ideal, but this only seems achievable if you use a ganache which will level itself off perfectly when piped. So far I've not been able to get a dark chocolate ganache to level off like that without adding so much liquid that it won't last more than 10-14 days.

-

Hi Jim, glad to hear I'm not the only one with this issue (I've been using a small spoon to scrape my peaks off too!). I've done a few butter ganaches, mainly just testing the ones in the Greweling book, but I find them a little sickly compared to a cream ganache. It's the eternal struggle between not wanting to compromise on your product, but also remembering that you're trying to run a business and need to make things practical. Aw meters are a bit beyond my budget, but I'm hoping that by following the guidelines set out by Wybauw and Morato in terms of ratios that I should be able to make something fairly stable and of a high quality, I just can't get it into the moulds without having to scrape the peaks off. I resorted to using the "slam filling" technique where you overfill and scrape off, but I felt that this weakened the bases and was worried that cracks would lead to spoilage. If you don't mind my asking, what sort of percentages do you aim for in your recipes in terms of water and sugar? Morato suggests <20% water and >30% sugars, but adding that much sugar to a dark ganache does affect the flavour significantly and I'm having difficulty getting the water content as low as 20% without creating a ganache which is almost solid when I pipe it.

-

Hi, thanks for the reply, your chocolates look gorgeous! I'd love to put 3 weeks on everything but sadly I don't have the turnover to make that practical. I was hoping to get 6 weeks, which is what a couple of local delis have told me would be the minimum for them to consider stocking my chocolates. I do make pralines and caramels that will last longer than that, but my customers say they can get those anywhere and really seem to want dark ganaches. My go-to ganache recipes are all high in cream so only last 2-3 weeks in good condition. A rough example would be around 500g couverture at 70% cocoa solids, 435g 35% cream, 50g invert sugar, 50g butter (based off a William Curley recipe). That recipe is just about pipeable but with a reasonably high water content, and some couvertures need even more cream to thin them out! If I try to lower the water and increase the sugars to extend shelf life it just gets even thicker! I'm trying to avoid preservatives and alcohols, but can't figure out how to make the ganache more fluid without adding liquid

-

Hi all, I'm a long time lurker on these forums and have learned a lot from reading the discussions. I'm in the process of converting my chocolate making hobby into a little business, and have been adapting my ganache recipes to give them a better shelf life for both myself and my customers. Having read the Wybauw book on shelf life and the various topics on the eG forums, I've been adapting my recipes to reduce the water content and increase the sugars, but this has resulted in real problems with viscosity, particularly with dark chocolate ganaches. I'm using melted and tempered chocolate with the liquids at around 35C, the resulting ganaches are beautifully smooth and shiny, but the texture is more like mayonaise when at piping temperature of 29C-31C. This would be fine for framing, but I make 90% moulded bonbons, and the ganaches are so thick that no amount of vibrating the mould will level it out, so I get peaks which need flattening and thick bases at the edges due to the doming of the ganache. Not ideal! I'm hoping the more experienced chocolatiers can advise on how to make ganaches more fluid at piping temperature, without just adding a load more liquid that would mess up the shelf life. Thanks, Sarah