boilsover

participating member-

Posts

918 -

Joined

-

Last visited

Content Type

Profiles

Forums

Store

Help Articles

Everything posted by boilsover

-

Copper vs Stainless Steel Clad Cookware: Is it worth the $$$?

boilsover replied to a topic in Kitchen Consumer

Gee, USDA, WHO, NIOSH, OSHA, all 50 states, and the world's dairy industries must have it wrong. Tin "poisoning" is a lot rarer than nickel sensitivity. Maybe you should reconsider stainless steel, too? http://www.ncbi.nlm.nih.gov/pubmed/23984718 Since you're into "pure scientific facts", care to substantiate a 351F melting point for tin? -

Copper vs Stainless Steel Clad Cookware: Is it worth the $$$?

boilsover replied to a topic in Kitchen Consumer

This is funny, since tin pest (like tin crying) is simply not an issue with linings, and pure tin melts 99F higher than you misbelieve and higher than all but a few oils' smokepoints. Have you lost any linings to tin pest? No place in modern restaurants? Have you not been paying attention to the lists of top-rated restaurants and photos of top chefs whose kitchens use it? -

Maybe too late for you kayb, but I hope the one you got is heavy enough. IME, most "Chinese cleavers" are too light and thin to last long at chopping bones and splitting things like... chops. I recommend people have at least one thick, heavy cleaver that can break bones for making stock, flattening meat, splitting hard squash, etc. Mine's a Fulton Brand by Foster Brothers, Model 1099. About 1/4" thick, with a big convex edge. I had my friend Bob Kramer sharpen and rescale her in cocobolo back before he became immortal. Splits kindling, too You should be able to find something similar on eBay...

-

I seriously doubt that. All their production has always been small (BCC/Hammersmith v1.0 couldn't even fill all its prepaid direct orders), and I'd be shocked if any retailers ever got any that could possibly find its way onto a liquidator's shelves. BCC v2.0 is just now in production, and those are full-on 3mm beauties. Kerry, if you saw copperware at a major liquidator, it was likely Baumalu, and perhaps some odd Mauviel pieces. Maybe in Canada, also Paderno PEI. If you did/do see any BCC wares in Homesense, would you please grab it for me?

-

Copper vs Stainless Steel Clad Cookware: Is it worth the $$$?

boilsover replied to a topic in Kitchen Consumer

Ummm, no. Try 449.5F for pure tin. I hope you didn't give all your copper away because of that mistake. And the melting temperature of a tin lining is substantially higher than that--all that is needed is something in the pan. Roasting at 500F is not a problem. I have actually (and accidentally) boiled tinned saucepans dry, one particular pan three times now. One of those times, the pan was so hot it glowed. While its tin was degraded to some degree, it did not destroy the lining. It was hotter--and for longer--than some pans which I have destructively tested by overheating. Here's what happens to seriously overheated clad. This pan's done. With tinned copper, the worst case is you have it retinned. -

Welcome to eGullet, Toronto. And thanks for your review. Few people here have spent much--if any--time cooking in thick, tin-lined bottoms, so you must excuse them for slamming this construction as antiquated. I believe Mac Kohler's Brooklyn Copper Cookware will succeed in much the same way that my friend Bob Kramer's knives have. Please post again when you've used these fabulous wares--with photos.

-

Copper vs Stainless Steel Clad Cookware: Is it worth the $$$?

boilsover replied to a topic in Kitchen Consumer

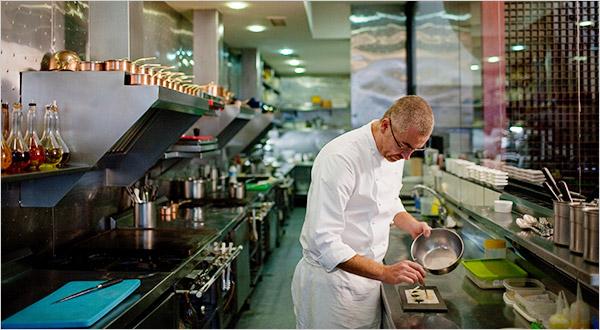

Here's Daniel Humm at Eleven Madison Park... In the background, what, bong water? Here're the Rocas at El Celler de Can Roca... What's that I see, Spanish bongwater? And here's Massimo Bottura at Osteria Francescana. Italian bong water, no doubt. And what's that in Virgilio Martinez's Central in Lima? Andean bong water! Heston Blumethal! What's that bong water doing on Din*ner's cooktops? Alex Atala, you Braziliam bum, what's that at D.O.M? Don't spill that on the carpet! Don't you all know copper cookware is "not for today"? -

Copper vs Stainless Steel Clad Cookware: Is it worth the $$$?

boilsover replied to a topic in Kitchen Consumer

You're funny. Here's a list of institutions and restaurants (you count their and chefs' stars) for which I can instantly find photos of chefs using copper: Palias De L'Elysee (Ch. Joel Normand) Senat (Ch Jean-Jacques Mathou) Assemblee Nationale (Ch. Christian Peccoud) Hotel de Matignon (Ch. Yves Delplace) Arpege (Ch. Alain Passard) Cazaudehore et la Forestiere (Ch. Gaston Haussais) La Closerie Des Lilas (Ch. Fabrice Vulin) Dalloyau (Ch. Pascal Niau) Fouquet's (Bernard Leprince) L'Intercontinental (Patrick Juhel) Le Grand Vefour (Guy Martin) Jacques Cagna (himself) Ledoyen (Ghislane Arabien) Lenotre (Gaston himself) Brasserie Lipp (Jean-Paul Juliard) Lucas Carton (Frederic Robert) Maxim's (Michel Kerever) Potel et Chabot (Jean-Pierre Bifi) Hotel Ritz (Guy Legay) Ritz Club (Domenique Fonseca) Bernard Dufoux (himself) La Cote Saint-Jacques (Michel Lorain) Les Crayers (Gerard Boyer) Au Crocodile (Emile Jung) L'Esperance (Marc Menau) Hotel Martinez (Christian Willer) Residence de la Pinede (Herve Quesnel) Paul Bocuse (himself) Les Pres D'Eugenie (Michel Guerard) Aubere Des Templiers (Francois Randolphe) Troisgros (Pierre and Michel) Georges Blanc (himself) Chez le Baron de Rothschild (Nadine, Robert Palluau) Seems they all are conspirators in this. You might also be surprised how many fans Brooklyn Copper Cookware has among the illuminati right there in New York City. I'll leave it to them to name names in their promotional materials. -

Copper vs Stainless Steel Clad Cookware: Is it worth the $$$?

boilsover replied to a topic in Kitchen Consumer

Yeah, even before Per Se, Keller's been part of the conspiracy perpetuating that top kitchens use copper... He may have even brought down the Towers... Don't actually see him cooking in it... must mean it's all an ornamental hoax! French Laundry must've relied on volunteers to polish it, too, since no one in a working kitchen does that? Hmmm? -

Copper vs Stainless Steel Clad Cookware: Is it worth the $$$?

boilsover replied to a topic in Kitchen Consumer

Yeah, well, they apparently faked the moon landing over at Daniel, too... From https://twitter.com/danielny -

Copper vs Stainless Steel Clad Cookware: Is it worth the $$$?

boilsover replied to a topic in Kitchen Consumer

Well, there's Craft. And Per Se. And Chef's Table at Brooklyn Fare. . According to Craft's Chef Damon Wise: "We use all-copper cookware for the meat because it heats up fast and offers even heat distribution,” Wise explained. “You get a better sear on the meat and it cooks faster.” http://www.craftrestaurantsinc.com/craft-new-york/gallery/ Here are a bunch more chefs, as compiled by Matfer: http://www.matferbourgeatusa.com/chef-spotlight-brendan-collins And Chris Consentino of Cockscomb. -

Copper vs Stainless Steel Clad Cookware: Is it worth the $$$?

boilsover replied to a topic in Kitchen Consumer

Yup, that's the idea--whisks supposedly "fit into the corners" better. While there is a little truth to this, and it makes intuitive sense, I think far too much is made of it. There are still "corners" that no round whisk will fit into. Try it with an empty pan--see how your favorite whisk's bottom radius differs from that of the "saucier"'s internal curvature. The old-style birch (twig and bent-cane) whisks, and many modern flexible or flat whisks reach into the "corners" of straight wall saucepans at least as well... As I said before, the curved "sauciers" have a lot of divergent proportions. Some of them have too-small footprints (which exacerbates poor conductivity), and the curvature means that surface:volume is not as linear as with Windsors when doing reductions. Some function OK as a hybrid saucepan and saute, but it's never a perfect balance. -

Copper vs Stainless Steel Clad Cookware: Is it worth the $$$?

boilsover replied to a topic in Kitchen Consumer

This is somewhat funny. I would submit that very high-BTU ranges evolved parallel to the decline in use of copperwares. Even a relatively weak gas hob can keep a copper bottom up and recover it faster. Copper's just far more efficient, and so there's mostly no need for high-output hobs for dry cooking. Again, you can easily go to 480F and above in tinned copper as long as there's fat in the pan by the time you near 437F. And really? For the fats I use in pans, there's no need to go any higher than that. -

Copper vs Stainless Steel Clad Cookware: Is it worth the $$$?

boilsover replied to a topic in Kitchen Consumer

Yes indeed, vessels that are strictly for heating or boiling thin liquids--the vapeurs, couscousiers, bain maries, chocolate and coffee kettles, poachers, etc.--needn't be thick. It doesn't hurt if they are, but thickness just doesn't make them work much better. The reason is that thin liquids develop very efficient convection currents. Thicken them up, though (or if you want to brown bones or sweat mirrepoix for your stock) and you'd better thicken the pan, too. FWIW, I can see value to having iron loop or ear handles on all these, rather than brass. The "ball peen" is called planishing, and is not ornamental, either. That beautiful hammered look actually hardens the copper, making it more resistant to dings and going out of round. Such "work hardening" is still valuable, even "today", as Falk and Mauviel press-form their pans. Your sauciers I would call 'Windsor', 'splayed saucepan' or a 'sauteuse evassee'. 'Saucier' as applied to cookware is a dubious modern term, and the pans which are called that are all over the board in terms of geometry. I think 'sauteuse bombee' would be a better name for the curved-wall "sauciers" being sold today. I have one small, single-pot copper and crockery bain marie. I have never miked the copper bottom, but it's quite thin. Ironically, mine was made by Waldow, to whose tooling Hammersmith and Brooklyn fell heir. Waldow once made a beautiful rotary bain marie holding multiple inserts; I'd like to have one. -

Copper vs Stainless Steel Clad Cookware: Is it worth the $$$?

boilsover replied to a topic in Kitchen Consumer

Now a thick pommes vapeur would not be my first choice to spend my money on, either. But a Tatin or Anna? Worth it to me. BTW, the pan on the work surface in the penultimate photo is new--as are others shown. -

Copper vs Stainless Steel Clad Cookware: Is it worth the $$$?

boilsover replied to a topic in Kitchen Consumer

Great, so they function better, but you deem the expense too high. I get that for tools I don't use much, but not for cooking. Well, if you went in to E. Dehillerin or Mora or A. Simon or Atelier du Cuivre you would likely find new in the >2.5mm range only those tin-lined pans still made by Mauviel. Last I checked, these were the rondeaux and some of the sauteuses. Or the very large, custom-order (80-800L) stockpots. I'm trying to follow your logic... If a pan is not new, it is unworthy? If the finest pans are generally older, then they're somehow not the finest or they shouldn't be in modern kitchens? This thread started with news about new thick, tinned copper, made in USA, being available. Would you be happier if I found photos of restaurants using those specific pans? The BCC pans are workhorses, much like the venerable pans in the photos. I think those pans will still be in service in 2116, when someone else will undoubtedly be branding them "not for today". -

Copper vs Stainless Steel Clad Cookware: Is it worth the $$$?

boilsover replied to a topic in Kitchen Consumer

Yes, sadly, "restaurant grade" (I prefer to call it "hotel grade" or "extra forte") is becoming historical, because so few makers can and will make in that thickness. Brooklyn and DH&M are doing it here in USA, Mazzetti in Italy, and Soye in Turkey, too. Smaller atelliers in France, no doubt. I find it amusing that the photographic proof fails to persuade you that high-end, busy, modern restaurant kitchens are happily using thick tinned copperware. Doubly so the idea that hanging pans is evidence of nonuse. I can assure you they're not ornamental. So, it's the price that makes it "not for today"? The solution to that is pretty easy--I scrounge my copper pieces (now somewhere around 50 pieces), and I've only ever purchased one new pan. None have cost more than their equivalents (not equals) in the premier-grade clad lines like Demeyere. I've had some new (to me) pieces retinned and silvered, but so far not any of the pans I've put into service needed retinning. There are cost and convenience issues with copper that can lead reasonable people to avoid it. But as far as pure performance goes, there's not much of an argument. Even today. However, there will be a new paradigm soon... -

Copper vs Stainless Steel Clad Cookware: Is it worth the $$$?

boilsover replied to a topic in Kitchen Consumer

Do you own any 3mm tinned copperware? Have you ever used any for any length of time? Let's just say we disagree on most of what you wrote: 1. There certainly is a difference between 3mm pans that have been tinned, and the 2.3mm and 1.8mm pans that Falk, Bourgeat and Mauviel make. Those latter makers may say their wares are 2.5mm thick, but (with a few exceptions within Mauviel) they are not 2.5mm of copper. 2. Tin linings are not "fragile". Even pans used for sauce work will last 10-15 years provided you use birch or coated whisks. 3. Tin linings are great for searing and saute. I don't know how you define heat for searing, but I say it starts at 200C/400F, which is below the melting temperature of 450F. Moreover, you can easily go higher with oil in the pan, and higher yet with food in it. If for you searing is flopping into a bare pan at 550F, then I wish you well. Tin linings, like SS to some degree, "season", but a seasoned tin lining always sticks less than a freshly-scoured SS one. 4. There are substantial and growing numbers of American retinners who do excellent work at reasonable prices. The going rate is $5 x (diameter + height in inches). Considering that the pans are also finely polished, it's not a bad deal. 5. Look in the state kitchens of France--copper predominates. 6. The responsiveness of 3mm tinned is a lot closer to SS-swaddled 2.3mm than you think. Without the evenness. There is a qualitative difference in the heat delivered from sidewalls, too. 7. If you do work out all the physics calculations (including thermal diffusivity and emissivity), copper is clearly superior to clad and aluminum in most applications. Superior enough for you? Maybe not. Bare aluminum wins every time on a cost:benefit analysis. 8. The BCC pans are definitely not just "collector pieces". -

Thanks, Franz: Are you going to include measurements for discontinued lines/pans as well? It might be useful for comparison purposes. Cheers!

-

There will be ridicule, but here's the #1 trick for removing odor from rubber, plastic and silicone. I learned this after nearly driving myself insane trying to remove freezer odors from my $$ silicone "rocks" ice molds. Seal the item in a plastic bag surrounded with... unscented clay cat litter. Leave for 2-3 days.

-

Interesting, thanks Smithy. Lots of variables at work. It would be useful to know how much water a given type of clay pot can hold within its walls, and how much (if any) passes through transpiration as opposed to evaporation around the cover.

-

OK. By the way, has anyone (e.g., Wolfort) done any real testing of the putuative benefits of cooking in clay? I readily understand how a porous clay vessel might soak up moisture (and pot liquor). But it's far less intuitive to me that the resulting prep would be any "moister". And the idea of a cover resulting in "self-basting" or doufeu-like condensation/precipitation just seems...wrong... considering the humidity inside and the thinness of the dripping condensate. I thought the spikes Staub touts were debunked awhile back. No? I propose that someone who loves these unglazed bean pots do a little 'sperimentin' with an accurate scale. But they sure are pretty, and I hope their sale supports some indigenous craftspeople.

-

The website's crazy slow, but there are deals. $80 of the 10.5Q All American pressure canner is the best deal I've seen so far. http://www.chefscatalog.com/product/31600-all-american-pressure-canner.aspx

-

Thank you for the information. I really appreciate it. I remain unclear about how the Mexican pots, by "strategy" or property, hold up to stovetop use better than Emile Henry's Flame line. The latter do not hold up all that well. I'm back to believing that, unless you must use the stovetop, clay vessels are best used in ovens.

-

Great, since you know a lot about clay wares that are suitable for the stovetop (and are not selling them, unlike Rancho) why don't you educatel me about how the Mexican pots are made differently from the Emile Henry--besides the glazing.