boilsover

participating member-

Posts

918 -

Joined

-

Last visited

Content Type

Profiles

Forums

Store

Help Articles

Everything posted by boilsover

-

Not earth-shaking, but a cool refinement on induction

boilsover replied to a topic in Kitchen Consumer

Does a 1500 or 1800 watt single hob fulfill all your stovetop needs? Is your Max Burton acceptably even-heating under your cookware? If so, this makes sense. I have 3 different induction hotplates, and I would be very unhappy if I had to give up my ranges. I think for 80% of what I do, 90% of the time, I could probably accept a double induction hob, and there are some good commercial versions that are stowable. But I would want 220v/3500W, and I would definitely want it built in. Everyone thinking of the "lab" concept should also consider case height and clearances. The 220v commercial units worth getting are tall (mine stands >6" off the counter and has a 39" overhead clearance to combustibles). They need big cases and wide clearances for ventillation/cooling/longevity reasons, so many home cooks would be disappointed to learn there isn't a lot of flexibility as to where you can put them. 6" above your existing counter, with a tall pot isn't fun or safe for a short cook; nor is building out all your counters 6" too low. Even if you want to go this route, it makes sense to put the appliance on a shorter table or in a well space built into the regular-height countertop. In any case, I think most cooks, home or pro, would end up using the appliance in only one place, even if they had more locations to choose from. Then there's home resale value to consider... -

Not earth-shaking, but a cool refinement on induction

boilsover replied to a topic in Kitchen Consumer

Sorry, I think in general this is product aimed less at cooking than it is decor and design. No serious restaurant is going to be firing regularly on a 110v/1500W hotplate that works like a tiny Murphy bed on 3 spindly legs. There are plenty of stout commercial 220v/3600W single hobs that can be moved and stowed as needed. Perhaps I'm outmoded, but the idea that a restaurant has to decide "If you need to cook" is outre. Cooking stations will always have a place. -

Not earth-shaking, but a cool refinement on induction

boilsover replied to a topic in Kitchen Consumer

This is not yet in the market, correct? The concept is fine, but it will probably be tippy. The original induction hobs introduced were designed to be placed under stone countertops. So if that can still be done, why would anyone want their hobs to hang on a wall? -

Ruhlman / Dalton Spoons, Utensils, and Kitchen Accessories

boilsover replied to a topic in Kitchen Consumer

I've never done it myself, but I've spent some time in foundries that make larger foodservice items, e.g., the clamshell griddle bodies for burger chains. Why would you want to work in cast iron if you didn't need to? -

Well, you can retherm soup on a $75 PIC with bad temperature control, too. It's where you need, e.g., 193F (and 189 and 198 won't do) that precision control would be nice. Have you plugged the Control Freak into a watt meter to see whether the draw is constant? And how often does the software sample the temp? My new Panasonic all-metal induction hob has 10F temperature granularity and is pretty accurate with pans that have SS's emissivity. I haven't felt any need for finer control than that.

-

Ruhlman / Dalton Spoons, Utensils, and Kitchen Accessories

boilsover replied to a topic in Kitchen Consumer

I await your response. You probably already know this, but aluminum is pretty easy to cast. -

Ruhlman / Dalton Spoons, Utensils, and Kitchen Accessories

boilsover replied to a topic in Kitchen Consumer

Do share. I work in cookware development. Send an NDA. It might be worth something. A variant of this, perhaps? -

Ruhlman / Dalton Spoons, Utensils, and Kitchen Accessories

boilsover replied to a topic in Kitchen Consumer

Kinda tough on a stovetop... -

Ruhlman / Dalton Spoons, Utensils, and Kitchen Accessories

boilsover replied to a topic in Kitchen Consumer

-

Ruhlman / Dalton Spoons, Utensils, and Kitchen Accessories

boilsover replied to a topic in Kitchen Consumer

Yup, that looks right. Fairly heavy and resists bending! -

Ruhlman / Dalton Spoons, Utensils, and Kitchen Accessories

boilsover replied to a topic in Kitchen Consumer

Dang, I'm not sure, I threw out the packaging. I was in a town last weekend with an outlet and this thread came to mind. Saw these on the Clearance table. -

Ruhlman / Dalton Spoons, Utensils, and Kitchen Accessories

boilsover replied to a topic in Kitchen Consumer

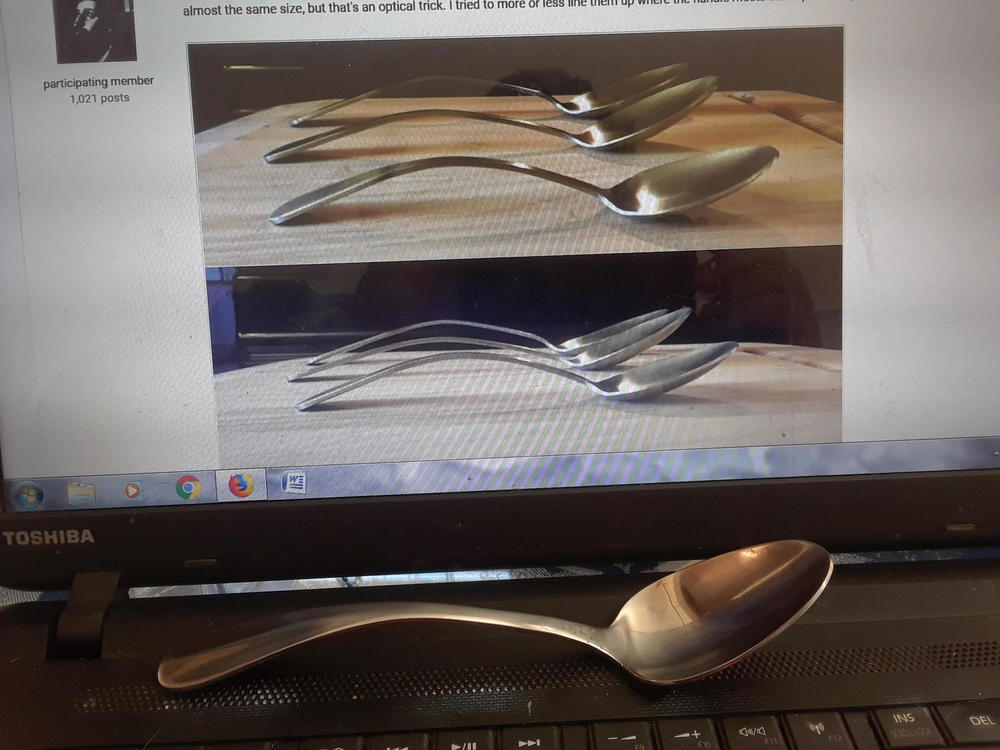

Hi, btbyrd: Here's a photo of the new, exclusive Boilsover Spoon pictured next to yours. Photo credits: btbyrds, boilsover and eGullet. Oneida 6-pack ($5) and a vise. $1 each plus $29.99 each shipping and handling. Reserve yours today! -

I'll try 1L in the same pan on a coil. I don't expect it'll be a lot slower.

-

Try boiling 4 liters of cold tap water on any of these 1500/1800W induction hotplates (about what I use for boiling pasta), and you are in for a long, frustrating experience. I just timed 1L to boil on a fairly wimpy gas hob... 2:52

-

Yard Sale, Thrift Store, Junk Heap Shopping (Part 3)

boilsover replied to a topic in Kitchen Consumer

Thanks, Andie! So were any European makers doing ECI before the Americans? And did the finish of the Griswolds you had hold up? -

Yard Sale, Thrift Store, Junk Heap Shopping (Part 3)

boilsover replied to a topic in Kitchen Consumer

Andie: Sorry, but can you please clarify? Did you have (or have you seen) American ECI from the 1920s? The reason I ask is DRU and Le Creuset seem to have started making ECI in the 1930s, which would be after they were first made here. Thanks! -

Yard Sale, Thrift Store, Junk Heap Shopping (Part 3)

boilsover replied to a topic in Kitchen Consumer

In this matter, Wiki is not the final authority, I'm sorry to say. There is much uncertainty. I believe lidded cast iron pots were imported into Great Britain from Holland before Darby visited to "borrow" the technology. So it may not be the particular sand-casting process that is the term's origin, but rather the country which first put them into trade. If you really want to research the name, you might locate a copy of "Dutch Ovens Chronicled, Their Use in the United States" by John G. Ragsdale, published by the University of Arkansas Press. -

Yard Sale, Thrift Store, Junk Heap Shopping (Part 3)

boilsover replied to a topic in Kitchen Consumer

DRU did not shut down. They've been in continuous operation since 1754, when 22-year-old Major George Washington was gearing up for the French and Indian wars. But you are correct that DRU produced enameled cast iron from the 1930s to the 1960s. Andie, do you have (or have you seen) any of the 1920s American ECI produced by Griswold, Wagner, Favorite, Lodge, Birmingham Stove & Range Co, Vollrath, or others? -

Yard Sale, Thrift Store, Junk Heap Shopping (Part 3)

boilsover replied to a topic in Kitchen Consumer

Umm, you've never heard of a Dutch oven? -

That, and hams, roasts and turkeys. And anything on 3/4 sheet pans. And hotel pans. And more than one pan at a time... And...

-

Might as well offer all the wedding guests Costco stool softener and CoQ10 at the same time.

-

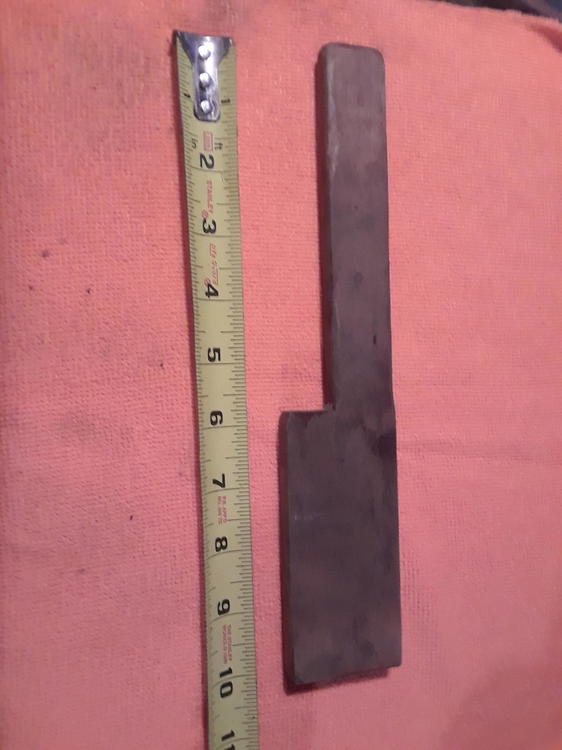

Hmmm, before I posted the photo, I tried posting a few tips from my tablet, and they're not showing up here. So here're shorter versions: 1. Spend extra time at 180 or 200 to get all the pits out. When you go to the next grit and turn 90 degrees, you will immediately see if you didn't get them all. In which case drop back to 180 or 200 at the original direction. Same story as you progress finer--if the current grit/direction isn't removing all the marks from the previous, you must go back. 2. If you use a block or wrap the paper on a file, you're going to be buying a lot of sandpaper. Doing it this way quickly clogs the grit before it can do much work. That's what the stick is for--you keep putting fresh abrasive in between the corner edge of the stick and the steel, and work only a few strokes, then shift the paper to a fresh area. I've found that 1"-wide "shop rolls" of emery cloth work really well, too. 3. The stick is about 1/4" thick. You want to use that short edge as your bearing surface. Such a tiny area under hand pressure and fresh grit is what does the work.

-

Here's a photo of the push stick. You only use the edge at the very corner closest to the "10" on the tape measure.

-

Yes, it looked full. A "rat-tail" tapered tang is a pretty good indicator of a well-made knife.

-

Thanks. Still a nice knife, just thicker than I thought. Does the tang taper back toward the butt end?